|

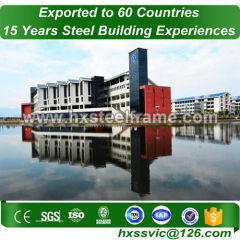

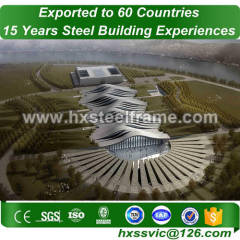

Shandong Huaxing Steel Structure Co., LTD.

|

40x60 steel building made of steel frame bh ASTM verified to Bhutan market

| Price: | 1000.0 USD |

| Payment Terms: | L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

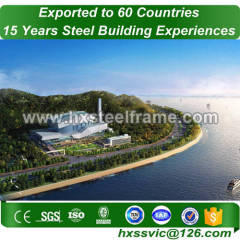

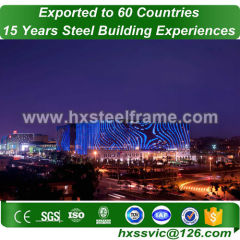

1. Exported to 80 nations UAE, Saudi Arabia, etc

2. Wall& Roof: EPS, Rock wall, PU sandwich etc

3. ISO9000, 14000, 18000 by BV France

1. 40x60 steel building ( made of steel frame ) main components description :

1 ) Mainly made by H - section and box girder .

Wide flanges make H - beam have a higher lateral stiffness fit for compression member .

Flanges of H - section with same thickness parallel with one another have strong resistance to bending , easy to composite and joint with other component for your prefab steel structure workshop .

2 ) Support System

Support system of prefab steel structure workshop mainly consist of purlin , cross bracing and angle brace made by Z - section , C - section or angle , allot the payload of column and pillar , transfer the loading to whole frame .

Support system makes the frame structure stand as a unity ; improve the solidity and stabilization of frame itself .

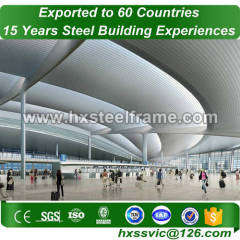

3 ) Roof and wall panel system

Roof and wall panel system mainly made of color steel or color steel sandwich panel .

Roof and wall panel system connected by self-tapping screw , easy and fast to assemble .

Good mechanical property as well as bearing capacity of prefab steel structure workshop .

Multiple color and surface finishing available meet your customization requirement and preference for prefab steel structure workshop .

2. About the product:

1) Product scope:

40x60 steel building ( made of steel frame ), steel structure warehouse / workshop / hangar / garage / poultry house, high rise steel building, industrial steel frame, sandwich panel, welded H steel, C/Z channel, corrugated steel sheet, etc.

2) Products structure type& Service:

Design & fabrication & Engineering Service, Steel Building, Space Frames, lattice steel structure, Tubular Steel Structures, basic building elements( built-up welded H-section, hot-rolled H-section, channel, steel column, steel beam), standard frames, secondary framing, roof & wall materials.

3. Project case- Shandong Weifang Metal Logistics Co., Ltd light steel structure warehouse, 17000 SQM:

Type: Welded H-Section Steel

Forming: Hot-Rolled Steel

Crane:with or Without(1 to 50 Tons)

External Wall Design: EPS/ Rock Wool/ Polyurethane/ MGO/ Cement Foam Panel

Life Time of Steel Frame:More Than 50 Years

Packing Method: Flat Pack, Open Top Container, by Steel Skid, etc.

Raw Materials: Q235/ Q345

Door: Sliding Door, Roller Door, Steel Door etc.

Window: PVC, Aluminium( Sliding and Fix)

4. DESIGN STANDARD& SOFTWARE for 40x60 steel building ( made of steel frame ) :

Standard: America Standard, Australia Standard, England Standard, China Standard, etc.

Software: SAP2000, Auto CAD, PKPM, RSTAB, PROE, MTS, Tekla Structures( Xsteel) , 3D3S, Tarch, etc.

5. Our seaworthy packing system for 40x60 steel building ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) How about the derust grade of your 40x60 steel building ( made of steel frame ) ?

Reply: Ball blasting Sa2.5 on main steel structure or by Galvanized frame;

manual derust St2.5 on secondary steel structure.

2) What kind of panel used for the roof and wall ?

Reply: Color corrugated steel sheet and sandwich panel could be used. Sandwich panel performs well on the heat insulation, sound insulation. Common sandwich materials are EPS, glass wool and PU sandwich panels.

3) Are 40x60 steel building ( made of steel frame ) expensive ?

Answer: The steel structure of our company is economic. Its technology and materials used decreases waste expenses such as wood, decorative stone, brick etc. All the material including the steel frames, wall body and roof for installation are prefabricated during the production process, therefore the labor costs for installation is decreased.