|

Shandong Huaxing Steel Structure Co., LTD.

|

prefab retail buildings made of light steel gauge with ISO for Moscow client

| Price: | 1000.0 USD |

| Payment Terms: | L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. QR code on Half part to ensure quality

2. Flexible layout to satisfy different requirements

3. Wall& roof: color steel board or sandwich pane

1. Technical specs for the prefab retail buildings ( made of steel frame ) :

Item name | Material characteristics | Material Grade | Surface Treatment |

Anchor bolt | Steel rod M24 , M27 | Q235B | |

Steel Column | H shape , Box , steel pipe , Hot rolled sheet | Q235B , Q345B | Paint or Hot dip galvanized |

H shape , steel Truss , Hot rolled sheet | Q235B , Q345B | Paint or Hot dip galvanized | |

Steel Bracing | Steel rod , Steel pipe , Angle steel | Q235B , Q345B | Paint |

Steel Purlin | C or Z shape , steel purlin Thickness :1.8mm ~ 3.0mm | Q235B , Q345B | Hot dip galvanized |

External wall panel , Roof panel | Sandwich panel with EPS , Rock wool , Pu , Glass wool | Steel T = 0.426 ~ 0.8mm , insulation T=50 ~ 150mm | Alu-zinc galvanized then painted |

Door | Sliding or rolling door | Steel or Aluminum sheet , T = 1.0 ~ 1.5mm | Paint or Hot dip galvanized |

Window | alloy-Glass , Aluminium alloy - shutter | T = 1.0 ~ 2.0mm | Alloy |

Day-lighting panel | FRP , T = 1.5mm or T = 1.8mm | Coefficient of thermal expansion : 2.2 x 10 - 5 / cm | Light transmittance 85% |

Ventilator | Turbine ventilator, ventilator along a slope | Steel , stainless steel , PC | Paint , 304 |

Gutter | Galvanized Steel plate , stainless steel plate | T = 2.0mm | Paint , 304 |

Downpipe | PVC pipe , T = 0.5mm | Φ110 , 160 , 200 | |

Bolt | Ordinary , high strength | 10.9S , 4.8s | Bluing for high strength bolts |

2. Why choose us as your steel structure supplier:

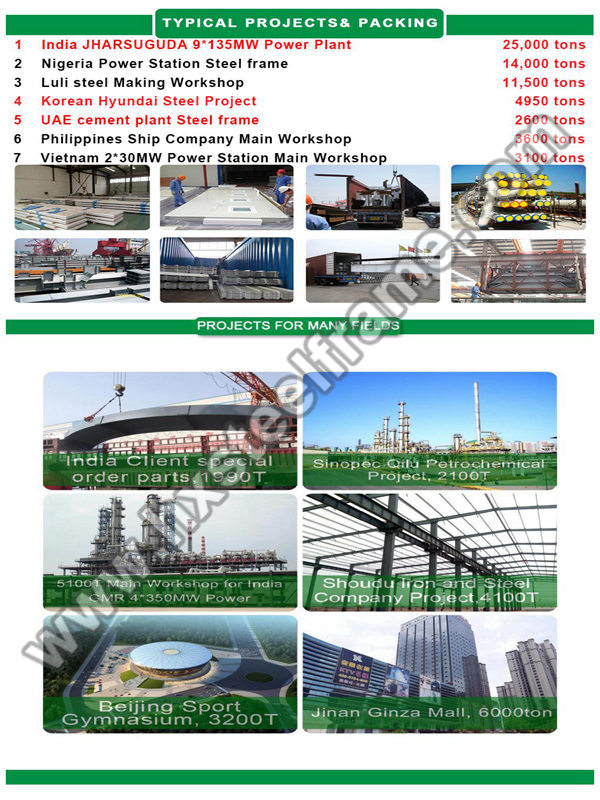

Founded in Shandong province, we are a professional manufacturer of steel structure building, workshop, warehouse, high rise building, industrial steel structure, civil steel structure, sandwich panel and profiled steel with ISO9001, SGS and CE certification.

We once made 30, 000 SQM prefabricated building in 16 days for a major buyer in Saudi Arabia. And, we manufactured 200, 000 square meter of prefabricated steel building monthly for post-Wenchuan Earthquake reconstruction. Our daily capacity is large 5, 0000 square meter and this is how we manage it:

1) 200, 000 square meter of factory space

2) 10 production lines for our prefabricated building series, 960 workers

3) 200 workers in charge of overseas construction

4) Our sales representatives can reply to your inquiries within eight hours in English, French and Japanese.

5) Two hundred workers oversee overseas construction.

6) We passed quality tests by India Adani Power, Hyundai Steel, China Construction Group, China Railway Construction Group and other biggest companies in the world.

3. Project case- Argentina Wugan warehouse, 2012:

Description: This project comprises a high specification industrial unit, factory and warehouse for a company producing electronic systems for industry. The building features an integrated two storey office facility, composite panel wall cladding and a curved roof with a standing seam system, barrel vault roof lights and a 10t travelling crane.

The client choose us after visited 6 China suppliers, when they came to our factory, we are producing and delivering steel structure for 9 countries, more than 20 containers are stuffing for 4 countries. No need more words, seeing is believing!

4. Our service for the product of prefab retail buildings ( made of steel frame ) :

1) We provide free design and technical support work: according to the plan, size requirements, use function and load conditions provided by the owner; we will provide free architecture scheme drawings, component detail drawings, installation instruction drawing, installation instructions files.

2) Coordination in product transportation

We' ll track products' transportation in whole course, and actively help customers solve all problems during product transportation.

3) Installation guidance

If our customer needs, we will assign engineers for on-site installation guidance work.

5. Our seaworthy packing system for prefab retail buildings ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Are you manufacturer or trader ?

We are manufacturer. Welcome to visit us at any time!

2) How can you avoid size error in supplying us the prefab retail buildings ( made of steel frame ) ?

We select international size error standards;

Use specified equipment to cut shear and rectify steel plate according to steel thickness;

Standard weld and installation order to lessen deformation.

3) What is the cost if we ask your engineers to assemble ?

Round-trip air tickets, eating, living, translation fee, visa fee and salary.

Our team include senior engineers with professor titles, first-class registered constructors, first-class registered structural engineers, first-class registered cost engineer, registered architect, American CWI engineer, EN TWI engineer, EN IWE welding engineer, American NACE painting engineer and various technicians with senior and medium professional titles.