|

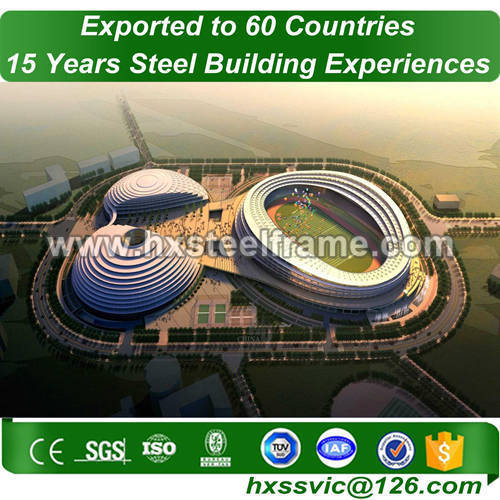

Shandong Huaxing Steel Structure Co., LTD.

|

modular education buildings made of heavy steel with ISO for project in Kenya

| Price: | 1000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Service: Design, fabrication, erection

2. Surface: hot dip galvanize, anti rust coating

3. Branded and reputed consumables are used

1. Specifications for the modular education buildings ( made of steel frame ) :

Items | Specification |

Length | Single slope , double slope , muti slope |

Width | Single span , double-span , Multi-span |

Height | single floor , double floors |

Column | Q235 , Q345 welded H section steel |

Beam | Q235 , Q345 welded H section steel |

Purlin | Q235 C channel or Z channel |

Knee brace | Q235 angle steel |

Vertical and traversal support | Q235 angle steel , round bar or steel pipe |

Tie bar | Q235 steel pipe |

Brace | Q235 round bar |

Cladding system | EPS , PU , Fiber glass wool sandwich panels or corrugated steel sheet with fiber glass wool insulation . available in Different colors & gauge |

Partition wall | sandwich panels ( EPS , PU , Fiber glass wool etc . ) available in Different colors & gauges |

Door | sandwich panel sliding door or roller door |

Gutter | stainless steel or color steel sheet |

Rainspout | PVC |

Live load on roof | In 120kg / Sqm ( Color steel panel surrounded ) |

Wind resistance grade | 12 grades |

Earthquake-resistance | 8 - 9 grades |

Structure usage | Up to 50 years |

Finishing options | vast array of colors and textures available |

Paint Options | Gray paint , red paint , white paint , epoxy zinc etc . Or Galvanized |

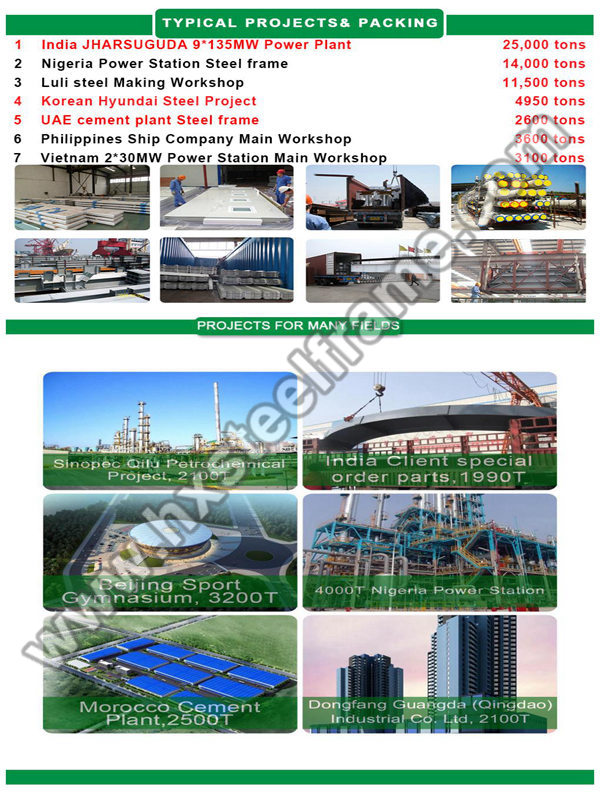

2. About our company:

1) We have a group of professional engineers, most of whom has more than 10 years' experiences in architecture field.

2) Established for more than ten years, our company has got a various of experiences in all kinds of steel structure& steel building design, manufacture, installation and so on. The work staffs have excellent skills. Some of them had helped customers to install the warehouse around the world.

3) We have the capacity of annually 200,000 tons steel structure. We also have possessed more than 300 sets of large precise and advanced processing equipment, including large gantry planning machines, automatic submerged arc welding machines, assembling machines, shot blasting machines and so on.

3. Project case- warehouse construction for Brazil Hidu logistics Park, 2014, 19, 200SQM:

Warehouse size is 160m length* 120m width* 15m height. Because the schedule is very tight, the contractor require to be completed within one month. Our company try our best to only use 25 days finish the project. Get government and Hidu Group highly praise.

Technical specification:

1) Column spacing: 6 m

2) Steel column: Q345, H500 * 200 * 10 * 12( GB)

3) Steel beam: Q345, H( 300-600) * 200 * 8 * 12( GB)

4) Roof purlin: C160 * 60 * 20 * 2.3( GB)

5) Wall purlin: C160 * 60 * 20 * 2.3( GB)

6) Column bracing: 25 steel round

7) Horizontal bracing: 25 steel round

8) Gutter water system: 3mm steel sheet, 160 PVC downpipe

9) Roof panel( outside): V-760, 0.5mm single board+ 75mm fiberglass+ aluminum foil

10) Wall panel: V-820, 0.5mm single board

11) Components paint: main structure sprayed 3 times, secondary frame for 2 times with iron red acrylic anti-rust paint and a medium gray alkyd primer

The client hired the SGS as the 3rd party QC, all WPS and QAP are adopting the highest international standard. We perfectly finish this project and won the trust of the client. Client told us, this is the real win-win business. Because we help them win the trust and profit from the owner due to our quick delivery with best quality.

4. Service we provided for the modular education buildings ( made of steel frame ) :

1) Pre-Sales Service:

Inquiry and consulting support.

View our Factory.

2) After-Sales Service:

Training how to install the steel structure, training

Engineers available to do some instruction of steel structure overseas.

5. Our seaworthy packing system for modular education buildings ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Why should I build steel building using steel structure ?

Steel has the higher strength.

80% recyclable, Steel is the most recycled material in the world.

No warping, no cracking, no chemical treatments.

Stronger connection.

Lower transport costs due to lightweight frames.

Steel frames will not burn, fire proof.

Lightning will not affect a steel framed house since steel creates a positive earth. Lightning energy is conducted straight to the ground.

Each steel structure is a independent engineered.

2) How difficult is it to install modular education buildings ( made of steel frame ) ?

Too easy! Some customers who purchase prefabricated steel building choose to install their own warehouse using local erection team.