|

Shandong Huaxing Steel Structure Co., LTD.

|

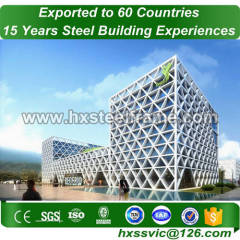

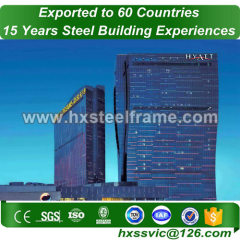

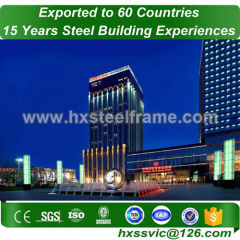

steel shop buildings and pre engineered metal buildings modern designed

| Price: | 1000.0 USD |

| Payment Terms: | L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. QR code on Finished part to ensure quality

2. Roof panel colour: white, blue, green, etc

3. Lead Time: Within 20days after receive deposit

1. Our excellent design team will design the steel shop buildings ( made of steel frame ) for you . If you give the following information:

1 ) Location ( where will be built ? ) _____ country , area

2 ) Size : Length * width * height _____ mm * _____ mm * _____ mm

3 ) wind load ( max . Wind speed ) _____ kn / m2 , _____ km / h , _____ m / s

4 ) snow load ( max . Snow height )

_____ kn / m2 , _____ mm

5 ) anti-earthquake _____ level

6 ) brick wall needed or not If yes , 1.2m high or 1.5m high

7 ) thermal insulation If yes , EPS, fiberglass wool , rock wool , PU sandwich panels will be suggested ; If not , the metal steel sheets will be ok . The cost of the latter will be much lower than that of the former .

8 ) door quantity & size _____ units , _____ ( width ) mm * _____ ( height ) mm

9 ) window quantity & size _____ units , _____ ( width ) mm * _____ ( height ) mm

10 ) crane needed or not If yes , _____ units , max . Lifting weight ____ tons ; Max . Lifting height ___m

2. Our Products Scope:

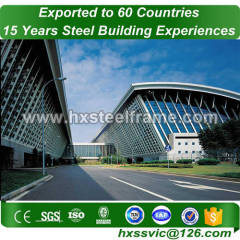

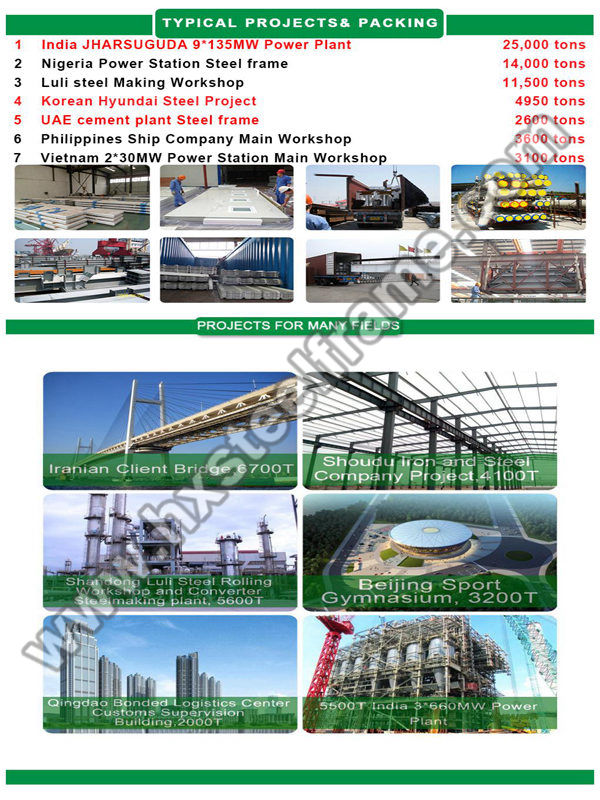

1) Steel Structure for industrial and power fields, such as power plant, steel mill, solar industry, hydroelectric plant, petrochemical fields, oil and gas pipeline, etc.

2) Steel Structure for civil fields, like high-rise building, heavy Steel Structure, workshop& warehouse, etc.

3. Project case- Qilu Petro-chemical Heavy Steel Workshop:

Size: 55000 square meter workshop, Single Span 39m, eave height 18m, mainly loading bear steel member over 100Ton, totally quantity of steel 6000Ton.

Steel Column: Q345B Four tube lattice column. Painted: 120um epoxy zinc painted.

Roof Structure: Q235B Pipe Truss Structure. Painted: 120um epoxy zinc painted.

Crane Beam: Q345B H section Steel Beam. Painted: 120um epoxy zinc painted.

Secondary Structure

Roof Horizontal Bracing: Q235B Angle Steel, Painted: three layer white color anti-rust Alkyd painted

Wall X Cross Bracing: Q235B Double Angle Steel, Painted: three layer white color anti-rust Alkyd painted

Tie Beam: Q235B Welding Pipe, Painted: three layer white color anti-rust Alkyd painted.

Roof Purlin: Galvanized C section steel

Wall Purlin: Galvanized C section steel

Steel Rod: Galvanized Steel Rod.

Panel system

Roof: 0.5mm Single Color sheet

Wall: 0.5mm Single Color sheet

4. The surface treatment for our steel shop buildings ( made of steel frame ) :

We have pretty good preservative treatment for steel frame as follows as per the highest international surface treatment code:

1) Clean the steel( reach to Sa2.5 Grade, China Code) , then we will spray paint:

Two layer epoxy zinc rich primer and 2 layer anti-rust paint( total thickness: 100-120um) ; Warranty period: 18-20 years under normal conditions.

2) Hot-dipped galvanized, when the thickness of parts is less than 5mm, thickness of hot-dipped gal is more than 65um; when equal to or more than 5mm, that is more than 86um. Warranty period: 45-50 years under normal conditions.

5. Our seaworthy packing system for steel shop buildings ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Are you manufacturer or trader ?

We are manufacturer. Welcome to visit us at any time!

2) How can you avoid size error in supplying us the steel shop buildings ( made of steel frame ) ?

We select international size error standards;

Use specified equipment to cut shear and rectify steel plate according to steel thickness;

Standard weld and installation order to lessen deformation.

3) What is the cost if we ask your engineers to assemble ?

Round-trip air tickets, eating, living, translation fee, visa fee and salary.

Our team include senior engineers with professor titles, first-class registered constructors, first-class registered structural engineers, first-class registered cost engineer, registered architect, American CWI engineer, EN TWI engineer, EN IWE welding engineer, American NACE painting engineer and various technicians with senior and medium professional titles.