|

Shandong Huaxing Steel Structure Co., LTD.

|

metal self storage buildings and structral steel workshop multi-story

| Price: | 1000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. 10 lines for steel frame produce, 960 workers

2. Lower cost and easy to maintenance and conserve.

3. We are an ISO 9001: 2000 certified com

1. Technical specs for metal self storage buildings ( made of steel frame ) :

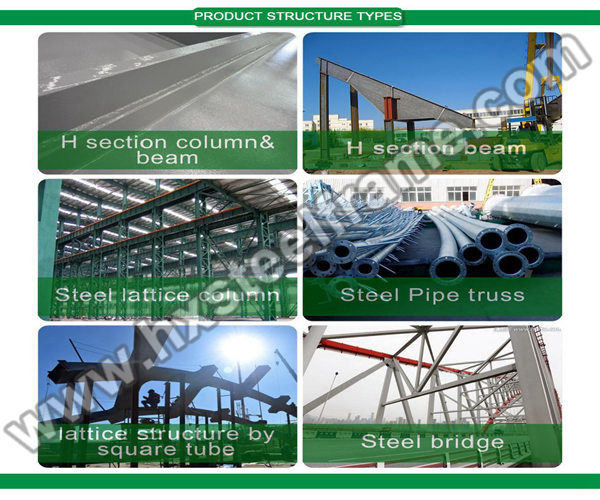

Specification | Structure type | |

Design standard | AISI / ASTM / BS / DIN / GB / JIS | |

Length | With customer's requirement | |

Width | Single span , double-span , multi-span | |

Height | With customer's requirement | |

Components | Bolt | Steel grade 45 |

Column | Q235B , Q345B welded H section steel | |

Beam | Q235B , Q345B welded H section steel | |

Tube | Steel Q235B , Q345B | |

High strength bolt | Cr 40 , 10.9S , 9.8S , galvanization | |

Sleeve | Steel Q235B , Q345B , galvanization | |

Purlin | Q235B C channel or Z channel , galvanization | |

Roof & Wall panel | Sandwich panels , Corrugated steel sheet , FRP sheet |

2. Why Our metal self storage buildings ( made of steel frame ) is your Right Choice:

1) Stable and deep financial capacity

Any investment is an important decision and should be realized through a financially stable company. Our deep community roots and stout economic strength gives us an exceptional advantage in hiring experienced professionals who will complete your project to your expectations.

2) Competitive Prices

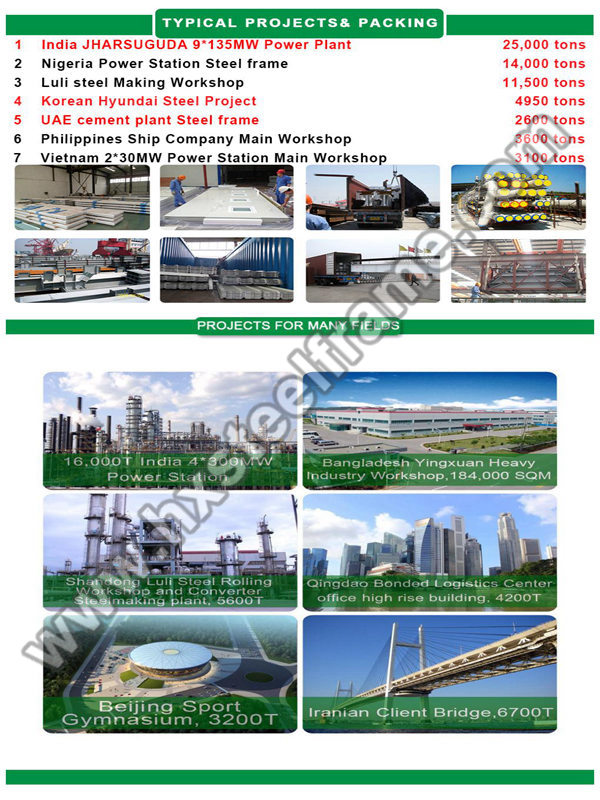

Our production capacity(approximately 200,000 metric tons annually) together with effective and economic engineering and manufacturing methods enable us to offer the most competitive prices in the industry.

3) Fast Quotations

Quotations for simple buildings can be submitted quickly due to vast experience of our staff and the advanced design software we use.

4) Fast Delivery

We are able to design, detail, fabricate and supply simple steel buildings in approximately 4 weeks. Most of our buildings are delivered and erected within 8 weeks(this relies on various factors such as site position, weather etc).

5) Site Supervision

A site supervisor is always present at site to ensure that work is being carried out satisfactorily. Any problems that arise are quickly dealt with to minimize any delays. Safety on site is also made a priority.

3. Project case- warehouse construction for Brazil Hidu logistics Park, 2014, 19, 200SQM:

Warehouse size is 160m length* 120m width* 15m height. Because the schedule is very tight, the contractor require to be completed within one month. Our company try our best to only use 25 days finish the project. Get government and Hidu Group highly praise.

Technical specification:

1) Column spacing: 6 m

2) Steel column: Q345, H500 * 200 * 10 * 12( GB)

3) Steel beam: Q345, H( 300-600) * 200 * 8 * 12( GB)

4) Roof purlin: C160 * 60 * 20 * 2.3( GB)

5) Wall purlin: C160 * 60 * 20 * 2.3( GB)

6) Column bracing: 25 steel round

7) Horizontal bracing: 25 steel round

8) Gutter water system: 3mm steel sheet, 160 PVC downpipe

9) Roof panel( outside): V-760, 0.5mm single board+ 75mm fiberglass+ aluminum foil

10) Wall panel: V-820, 0.5mm single board

11) Components paint: main structure sprayed 3 times, secondary frame for 2 times with iron red acrylic anti-rust paint and a medium gray alkyd primer

The client hired the SGS as the 3rd party QC, all WPS and QAP are adopting the highest international standard. We perfectly finish this project and won the trust of the client. Client told us, this is the real win-win business. Because we help them win the trust and profit from the owner due to our quick delivery with best quality.

4. Drawings & Quotation for the metal self storage buildings ( made of steel frame ) :

1) Customized design to welcome.

2) As long as you like, we can design and provide drawings for you. Just give the technical data and your demand, we will give you the best offer.

3) In order to give you an exactly quotation and drawings, please tell us the Length, width, eave height and local weather. We'll quote for you prompt.

5. Our seaworthy packing system for metal self storage buildings ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Q: How could I control the cost of building a metal self storage buildings ( made of steel frame ) ?

A: Firstly, the designing scheme should be mutually discussed and then accepted. Then, the kinds of building materials should be confirmed since different types and qualities make various prices. After that, we will send you a detailed quotation.

2) Q: How Long does it take to build a metal self storage buildings ( made of steel frame ) ?

A: It depends on the size of the warehouse. Generally, the construction period of is 1 month of a 2000-square-meter workshop by a construction team of 8-10 people. It only costs 2-3 weeks to build the steel structure frame.

3) Q: Is it difficult to build a metal self storage buildings ( made of steel frame ) ?

A: totally not, you can let your local teams build it according to the construction drawings and erection guiding video provided by us.