|

Shandong Huaxing Steel Structure Co., LTD.

|

metal storage building kits and structral steel workshop with SGS certificate

| Price: | 1000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Exported to 80 countries UAE, Saudi Arabia, Iraq etc

2. Lower cost and easy to maintenance and conserve.

3. Structure connected with high in

1. Data of the metal storage building kits ( made of steel frame ) :

Specification | |

Material : | Grade Q235 , equivalent to ASTM A36 Grade Q345 , equivalent to ASTM A572 |

Section : | Any product shape according to customer's requirements |

Certification : | ISO quality system , Chinese GB50221 - 2001 |

Sand Blast : | SA 2.5 Sand blasting |

Welding Technology : | Single level butt welding , fillet welding by electric arc welding , and Gas shielded welding |

Surface treatment : | Hot dip galvanized , Epoxy zinc rich primer Standard : ISO1461 ( 1999 ) , JIS H 8641 - 1999 , ASTM A 123 / A 123M-02 |

Welding Testing | Ultrasonic Testing , X-ray Testing |

Manufacturing Technology | Drilling , Cutting , Assembling , Welding , Rectification , Testing etc |

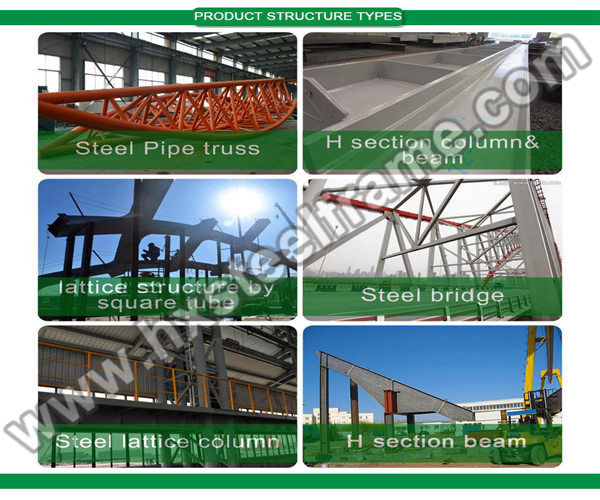

2. Our Products Scope:

1) Steel Structure for industrial and power fields, such as power plant, steel mill, solar industry, hydroelectric plant, petrochemical fields, oil and gas pipeline, etc.

2) Steel Structure for civil fields, like high-rise building, heavy Steel Structure, workshop& warehouse, etc.

3. Project case- Argentina Steel Structure workshop Building:

We are the largest steel structure building materials supplier and manufacturer in Shandong, China.

This steel structure building used for workshop built in 2010 year for our Argentina Customer.

Project Conditions:

1) Size: 5930M2

Main workshop area 80m long* 60m wide* 9m Eaves height( ridge height 10m)

Affiliated workshop area: 1130 square meter.

2) Wall & roof material: V-960 light steel sandwich panel

3) Thermal Insulation: 50mm EPS foam, 12kg/ m3

4) Wind load: 0.79kn/ M2

5) Crane: 8 cranes( lifting capacity: 2 ton)

6) Windows and doors: electrical rolling window&doors, aluminium alloy

4. The surface treatment for our metal storage building kits ( made of steel frame ) :

We have pretty good preservative treatment for steel frame as follows as per the highest international surface treatment code:

1) Clean the steel( reach to Sa2.5 Grade, China Code) , then we will spray paint:

Two layer epoxy zinc rich primer and 2 layer anti-rust paint( total thickness: 100-120um) ; Warranty period: 18-20 years under normal conditions.

2) Hot-dipped galvanized, when the thickness of parts is less than 5mm, thickness of hot-dipped gal is more than 65um; when equal to or more than 5mm, that is more than 86um. Warranty period: 45-50 years under normal conditions.

5. Our seaworthy packing system for metal storage building kits ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Is there a clear service life of your metal storage building kits ( made of steel frame ) ? If have, how long ?

Under conventional climate and environment, steel structure whole building 30 years, main structure 50 years, protecting system 30 years.

2) What designs do you have in different climates? How can the metal storage building kits ( made of steel frame ) adopt to different climates?

Strong wind region: improve the wind-resisting ability of the internal structure.

Cold region: increase the thickness of the wall, or use good insulation material, improve anti-pressure ability of the structure.

High corrosion region: use corrosion resistant material, or paint anti-corrosive coating.