|

Shandong Huaxing Steel Structure Co., LTD.

|

steel metal fabrication formed 30x60 metal building with CE at Nairobi area

| Price: | 1000.0 USD |

| Payment Terms: | L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Delivery time: strictly based on contract

2. Good environmental protection effect

3. Door for workshop: Rolled up door or Sliding door

1. Steel building ( made of steel metal fabrication ) main components description :

1 ) Mainly made by H - section and box girder .

Wide flanges make H - beam have a higher lateral stiffness fit for compression member .

Flanges of H - section with same thickness parallel with one another have strong resistance to bending , easy to composite and joint with other component for your prefab steel structure workshop .

2 ) Support System

Support system of prefab steel structure workshop mainly consist of purlin , cross bracing and angle brace made by Z - section , C - section or angle , allot the payload of column and pillar , transfer the loading to whole frame .

Support system makes the frame structure stand as a unity ; improve the solidity and stabilization of frame itself .

3 ) Roof and wall panel system

Roof and wall panel system mainly made of color steel or color steel sandwich panel .

Roof and wall panel system connected by self-tapping screw , easy and fast to assemble .

Good mechanical property as well as bearing capacity of prefab steel structure workshop .

Multiple color and surface finishing available meet your customization requirement and preference for prefab steel structure workshop .

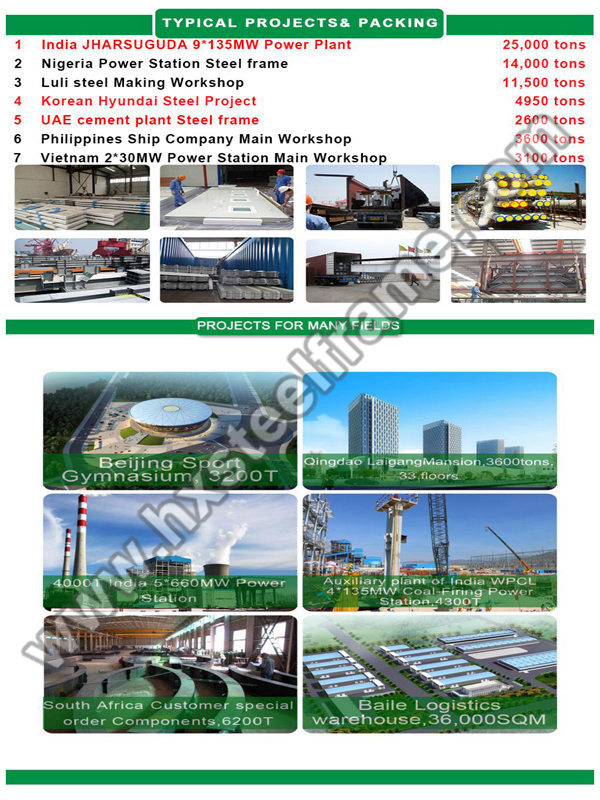

2. Our products scope include:

Single layered light and MID-sized workshops and warehouses, Steel building ( made of steel metal fabrication ), single layered heavy duty workshops, wide-span public buildings, high-layered and super high-layered buildings, muti-layered industrial workshops, office buildings and houses, bridges, wide-span highway bridges and bridges in city, viaducts; industrial platform and support; structures that can be dismantled and transported, etc

3. Project case- Qilu Petro-chemical Heavy Steel Workshop:

Size: 55000 square meter workshop, Single Span 39m, eave height 18m, mainly loading bear steel member over 100Ton, totally quantity of steel 6000Ton.

Steel Column: Q345B Four tube lattice column. Painted: 120um epoxy zinc painted.

Roof Structure: Q235B Pipe Truss Structure. Painted: 120um epoxy zinc painted.

Crane Beam: Q345B H section Steel Beam. Painted: 120um epoxy zinc painted.

Secondary Structure

Roof Horizontal Bracing: Q235B Angle Steel, Painted: three layer white color anti-rust Alkyd painted

Wall X Cross Bracing: Q235B Double Angle Steel, Painted: three layer white color anti-rust Alkyd painted

Tie Beam: Q235B Welding Pipe, Painted: three layer white color anti-rust Alkyd painted.

Roof Purlin: Galvanized C section steel

Wall Purlin: Galvanized C section steel

Steel Rod: Galvanized Steel Rod.

Panel system

Roof: 0.5mm Single Color sheet

Wall: 0.5mm Single Color sheet

4. Engineering design advantage for the Steel building ( made of steel metal fabrication ) :

Our people have a good knowledge and full grasp of various PEB specifications and international codes, which are predominant building specifications and standards in America, Europe and worldwide, such as BS, MBMA, AISC, AISI and so forth. We have fully developed a proprietary technical system that targets the tasks of PEB engineering, engineering optimization, and further engineering. Our engineering people are also versed in utilization and application of main-stream commercial design software including STAAD, SAP2000, PKPM, STRUCAD, XSTEEL etc.

Our company owes its competitiveness, in great part, to its flexibility, efficiency and optimization of designs for structure and cladding. Our structural engineers are not only masters in terms of structural design, but also extremely professional and skillful in cladding system design. They are intimately familiar with categories, functions, combinations and applications of different types of roof and wall panels. Therefore the building system we offer our customers is simply more human-friendly, safer and more cost-effective and features greater architectural beauty.

5. Our seaworthy packing system for Steel building ( made of steel metal fabrication ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) I just need a small Steel building ( made of steel metal fabrication ), do you accept small order ?

It' s no problem, we would like to grow up with you together.

2) I am a designer; Can you help me to produce the steel structure which we designed ?

Our mission is to help customers to be successful. So it' s welcome if we can help you solve problem and make your design come true.

3) Can you offer Door to Door service ? Because i do not know how to do customs clearance.

Yes. We can make Door to Door service to help you save much time of shipping. Also we have big discount with shipping company because we have do much of this every day. So it will save your time also money.