|

Shandong Huaxing Steel Structure Co., LTD.

|

modular retail buildings made of welded H column ISO verified provide to Egypt

| Price: | 1000.0 USD |

| Payment Terms: | L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

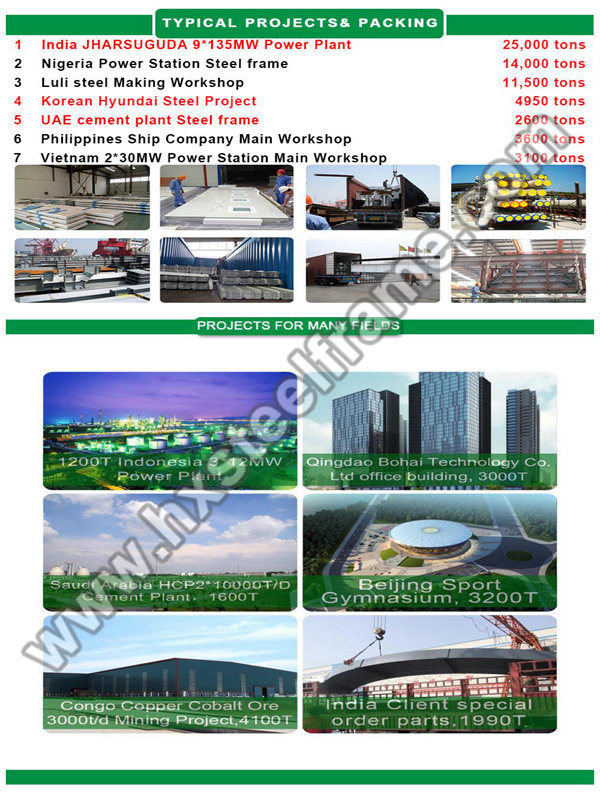

1. Top serviced client like SIEMENS, GE, Adani, Hyundai

2. Save time: All the items are factory-made

3. Structure connected with high intensity

1. Technical specs of the modular retail buildings ( made of steel frame ) :

The modular retail buildings ( made of steel frame ) were designed , constructed and installed by us who are professional on designing , processing and installing of steel structure building . You may give us your own drawings to enable us construct as per your request or you might just give us your ideas , we can design the project based on your ideas . Buildings of steel structure are safe , easy to install and disassemble . This steel structure can be used multiple times without special tools .

1 ) size :

MOQ is 1000 square meter , length X width X eave height , roof slope

2 ) type :

single slope , double slope , muti-slope ; single span ,

double-span , Multi-span , single floor , double floors

3 ) base :

Concrete and steel foundation bolts

4 ) column and beam :

material Q345 ( S355JR ) or Q235 ( S235JR ) steel , all bolts connection , straight cross-section or Variable cross-section

5 ) bracing :

X or V or other type bracing made from angle , round pipe etc .

6 ) c or z purlin ,

size from C100 ~ C320 , Z160 ~ Z300

7 ) roof and wall panel :

single colorful corrugated steel sheet 0.326 ~ 0.6mm thick , YX26-205-820 ( 820mm wide )

single colorful corrugated steel sheet 0.326 ~ 0.6mm thick , YX15-225-900 ( 900mm wide )

single colorful corrugated steel sheet 0.326 ~ 0.6mm thick , YX35-125-750 ( 750mm wide )

single colorful corrugated steel sheet 0.376 ~ 0.6mm thick , YX51-380-760 ( 760mm wide )

single colorful corrugated steel sheet 0.376 ~ 0.6mm thick , YX51-470 ( 470mm wide )

sandwich panel with EPS , rock wool , glass wool , PU etc insulation thickness around 50mm ~ 150mm , width 950mm or 960mm !

8 ) accessories :

Semi - transparent skylight belts , Ventilators , down pipe , out gutter etc

9 ) surface :

Paint or hot dip galvanized

10 ) packing :

main steel frame without packing load in 40'OT , roof and wall panel load in 40' HQ

2. Company Advantages:

Our Corporation is able to offer complete services for pre-engineered buildings and steel structure projects including: design, fabrication, erection and after-sales services. This integrated production process will bring to our customers huge advantages of an optimal solution, high-quality products and perfect services.

WHAT MAKES US DIFFERENT ?

1) Competitive price

The advanced self-contained high automatic design production line along with experienced and professional staffs help us to bring out the most competitive price.

2) Quality assurance

We produces all structural components of pre-engineered buildings, steel structure projects at the factory with ISO 9001: 2008 quality control system. we have a Quality Control Department who guarantees our products to meet international standards.

3) Fast delivery

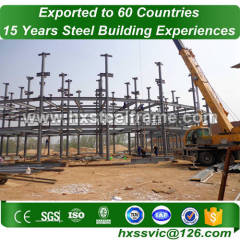

With 200, 000 m2 of manufacturing factory and a professional highly trained erection team who is strictly supervised by project management board, we are committed to manufacturing and provide products on schedule.

3. Project case- Russia Office Building, workshop and warehouse Project, 2012:

Detailed introduction

Project Scale: 3-floor heavy office building, 10ton crane in workshop and warehouse, total 3 buildings, tonnage 1240ton

Project scope: Construction drawings design, shop-drawing design, material procurement, steel structure fabrication and painting, and floor deck

4. Our service for the product of modular retail buildings ( made of steel frame ) :

1) We provide free design and technical support work: according to the plan, size requirements, use function and load conditions provided by the owner; we will provide free architecture scheme drawings, component detail drawings, installation instruction drawing, installation instructions files.

2) Coordination in product transportation

We' ll track products' transportation in whole course, and actively help customers solve all problems during product transportation.

3) Installation guidance

If our customer needs, we will assign engineers for on-site installation guidance work.

5. Our seaworthy packing system for modular retail buildings ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Q: How could I control the cost of building a modular retail buildings ( made of steel frame ) ?

A: Firstly, the designing scheme should be mutually discussed and then accepted. Then, the kinds of building materials should be confirmed since different types and qualities make various prices. After that, we will send you a detailed quotation.

2) Q: How Long does it take to build a modular retail buildings ( made of steel frame ) ?

A: It depends on the size of the warehouse. Generally, the construction period of is 1 month of a 2000-square-meter workshop by a construction team of 8-10 people. It only costs 2-3 weeks to build the steel structure frame.

3) Q: Is it difficult to build a modular retail buildings ( made of steel frame ) ?

A: totally not, you can let your local teams build it according to the construction drawings and erection guiding video provided by us.