|

Shandong Huaxing Steel Structure Co., LTD.

|

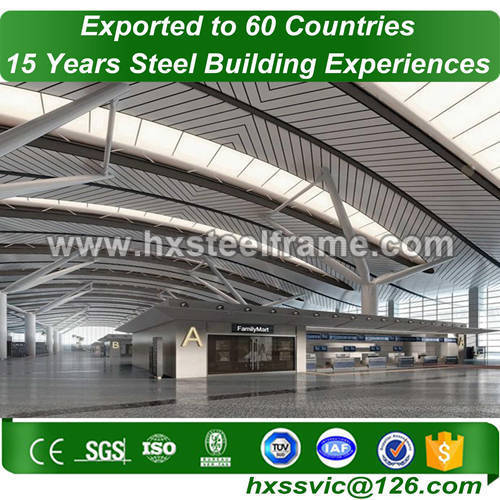

prefab hotels and modular commercial buildings on sale to Iraq customer

| Price: | 1000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Main frame shipped in bulk carrier or container

2. Free to design architectural drawings for you;

3. High quality welding process are used

1. prefab hotels ( made of steel frame ) main components description :

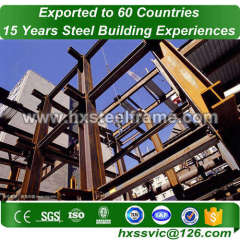

1 ) Mainly made by H - section and box girder .

Wide flanges make H - beam have a higher lateral stiffness fit for compression member .

Flanges of H - section with same thickness parallel with one another have strong resistance to bending , easy to composite and joint with other component for your prefab steel structure workshop .

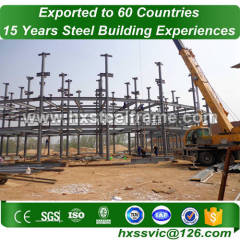

2 ) Support System

Support system of prefab steel structure workshop mainly consist of purlin , cross bracing and angle brace made by Z - section , C - section or angle , allot the payload of column and pillar , transfer the loading to whole frame .

Support system makes the frame structure stand as a unity ; improve the solidity and stabilization of frame itself .

3 ) Roof and wall panel system

Roof and wall panel system mainly made of color steel or color steel sandwich panel .

Roof and wall panel system connected by self-tapping screw , easy and fast to assemble .

Good mechanical property as well as bearing capacity of prefab steel structure workshop .

Multiple color and surface finishing available meet your customization requirement and preference for prefab steel structure workshop .

2. Why Our prefab hotels ( made of steel frame ) is your Right Choice:

1) Stable and deep financial capacity

Any investment is an important decision and should be realized through a financially stable company. Our deep community roots and stout economic strength gives us an exceptional advantage in hiring experienced professionals who will complete your project to your expectations.

2) Competitive Prices

Our production capacity(approximately 200,000 metric tons annually) together with effective and economic engineering and manufacturing methods enable us to offer the most competitive prices in the industry.

3) Fast Quotations

Quotations for simple buildings can be submitted quickly due to vast experience of our staff and the advanced design software we use.

4) Fast Delivery

We are able to design, detail, fabricate and supply simple steel buildings in approximately 4 weeks. Most of our buildings are delivered and erected within 8 weeks(this relies on various factors such as site position, weather etc).

5) Site Supervision

A site supervisor is always present at site to ensure that work is being carried out satisfactorily. Any problems that arise are quickly dealt with to minimize any delays. Safety on site is also made a priority.

3. Project case- Angola Dashan workshop, 2014:

Description: This project consists of a 50m wide x 160m long x 9m to eaves, twin portal frame building, comprising steelwork and roof and wall cladding. Including insulated gutters, siphonic drainage system and roller shutter doors. The scheme also includes the supply and installation of 6 no 10t overhead travelling cranes, high bay lighting and general electrics.

4. Our service for the product of prefab hotels ( made of steel frame ) :

1) We provide free design and technical support work: according to the plan, size requirements, use function and load conditions provided by the owner; we will provide free architecture scheme drawings, component detail drawings, installation instruction drawing, installation instructions files.

2) Coordination in product transportation

We' ll track products' transportation in whole course, and actively help customers solve all problems during product transportation.

3) Installation guidance

If our customer needs, we will assign engineers for on-site installation guidance work.

5. Our seaworthy packing system for prefab hotels ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Are you manufacturer or trader ?

We are manufacturer. Welcome to visit us at any time!

2) How can you avoid size error in supplying us the prefab hotels ( made of steel frame ) ?

We select international size error standards;

Use specified equipment to cut shear and rectify steel plate according to steel thickness;

Standard weld and installation order to lessen deformation.

3) What is the cost if we ask your engineers to assemble ?

Round-trip air tickets, eating, living, translation fee, visa fee and salary.

Our team include senior engineers with professor titles, first-class registered constructors, first-class registered structural engineers, first-class registered cost engineer, registered architect, American CWI engineer, EN TWI engineer, EN IWE welding engineer, American NACE painting engineer and various technicians with senior and medium professional titles.