|

Shandong Huaxing Steel Structure Co., LTD.

|

workshop and steel warehouse construction to ISO code preeminently created

| Price: | 1000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Steel structure component be in nude package

2. Connection of steel structure: weld or bolt

3. Guarantee: The main structure over 35 to 50 years

1. components and materials of the workshop ( made of steel frame ) :

Main structure | Welded H section , Lattice structure , Tubular column or beam , space frame etc |

Purlin | C Section Channel or Z Section Channel |

Roof Cladding | Sandwich Panel or Corrugated Steel Sheet with Fiber Glass Wool Coil |

Wall Cladding | Sandwich Panel or Corrugated Steel Sheet |

Tie Rod | Circular Steel Tube |

Brace | Round Bar |

Column & Transverse Brace | Angle Steel or H Section Steel or Steel Pipe |

Knee Brace | Angle Steel |

Roof Gutter | Color Steel Sheet |

Rainspout | PVC Pipe |

Door | Sliding Sandwich Panel Door or Metal Door |

Windows | PVC/Plastic Steel/Aluminum Alloy Window |

Connecting | High Strength Bolts |

Packing | Decided by you , loaded into 1X 40ft GP , 1X20 ft GP , 1X40 ft HQ |

Drawing | We can make the design and quotation according to your require or your drawing |

2. Applications of steel structure:

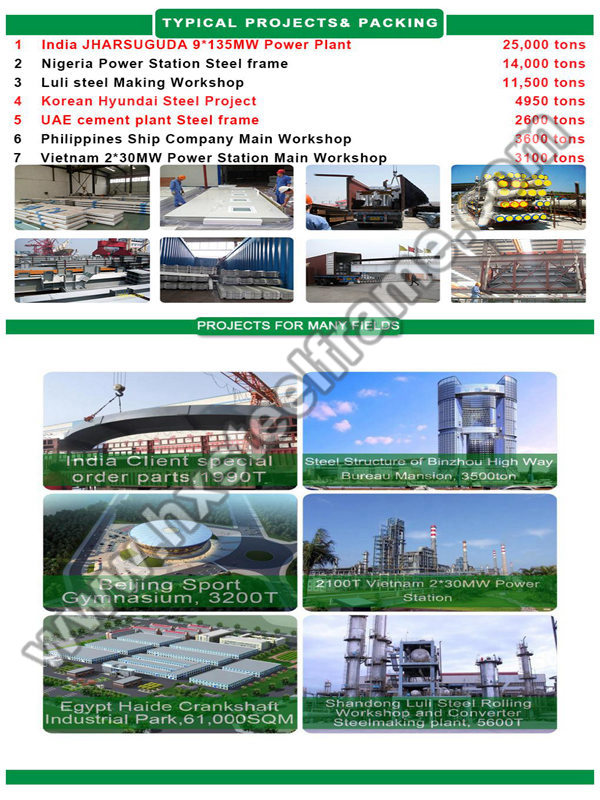

Structural steel fabrication have become increasingly and widely used at the workshops, warehouse, workshop ( made of steel frame ) and other industrial and civil architectures. For example, single-span and multi-span gantry light-frame structures, exhibition Hall, industrial steel frame, Office buildings, Garage, Multy-story building, Hanger, Agricultural storage, Logistic centers, and all kinds of steel construction, etc.

3. Project case- West Chuang Company Steel Structure Workshop / Light steel structure warehouse:

1) Roof: Color-coated Corrugated Steel Sheet with skylight panel

2) Wall: Color-coated Corrugated Steel Sheet

3) Main Steel Framework: Steel Column, Beam, Purlin and other supporting parts with shot blasting and painting process.

4) Material: Q345

5) Window: Plastic Steel Window

6) Door: Sliding Door plus Canopy(all are made by sandwich panel)

7) PVC Downpipe

8) Total 3000tons

4. What you can get from us for your demanded workshop ( made of steel frame ) :

1) Steel structure special designing and processing

2) EPS sandwich panel( for wall, roof, floor)

3) All construction & decoration materials &downpipe are strictly selected.

4) Designing & Installation drawings( in details)

5) Full support in installation technology & guidance

6) Engineers' guidance on-site in your place is available

7) Custom-made service is available

5. Our seaworthy packing system for workshop ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Is there a clear service life of your workshop ( made of steel frame ) ? If have, how long ?

Under conventional climate and environment, steel structure whole building 30 years, main structure 50 years, protecting system 30 years.

2) What designs do you have in different climates? How can the workshop ( made of steel frame ) adopt to different climates?

Strong wind region: improve the wind-resisting ability of the internal structure.

Cold region: increase the thickness of the wall, or use good insulation material, improve anti-pressure ability of the structure.

High corrosion region: use corrosion resistant material, or paint anti-corrosive coating.