|

Shandong Huaxing Steel Structure Co., LTD.

|

prefab buildings made of steel stuctures by Q235 Q345B accurately processed

| Price: | 1000.0 USD |

| Payment Terms: | L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Customers or us specifying freight forwarder

2. Material: steel frame, sandwich panel, Q235

3. Our products have been export to 50 countries

1. Data of the prefab buildings ( made of steel frame ) :

Specification | |

Material : | Grade Q235 , equivalent to ASTM A36 Grade Q345 , equivalent to ASTM A572 |

Section : | Any product shape according to customer's requirements |

Certification : | ISO quality system , Chinese GB50221 - 2001 |

Sand Blast : | SA 2.5 Sand blasting |

Welding Technology : | Single level butt welding , fillet welding by electric arc welding , and Gas shielded welding |

Surface treatment : | Hot dip galvanized , Epoxy zinc rich primer Standard : ISO1461 ( 1999 ) , JIS H 8641 - 1999 , ASTM A 123 / A 123M-02 |

Welding Testing | Ultrasonic Testing , X-ray Testing |

Manufacturing Technology | Drilling , Cutting , Assembling , Welding , Rectification , Testing etc |

2. Company Brief:

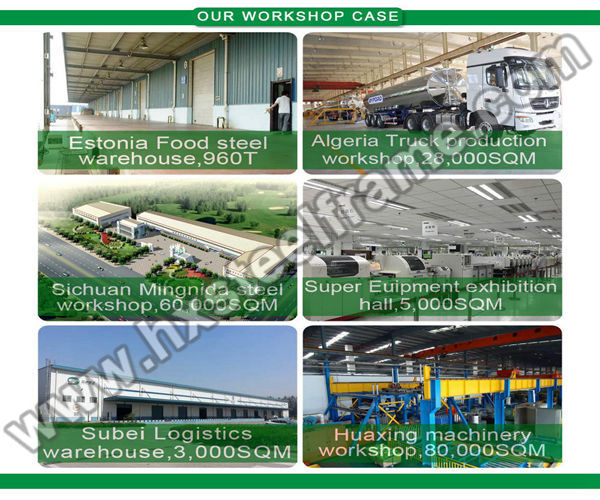

Founded in Shandong, we are one of the most powerful enterprises of steel building and steel structure in China.

Area of Main factory: 360,000 square meters and the 200,000 square meters' workshops.

Total number of staff: 960 persons, details are as follow:

Number of Admin Staff: 140.

Number of Marketing and Sales: 102.

Number of Architectural Designers: 58

Number of In Line QC: 38.

Number of regular workers for production and installation of prefab buildings ( made of steel frame ) : 600

We have the experience to do the big projects with the top rank construction company in the world, we are always showing our best service and professionalism, and we have exported the steel structure buildings to more than 110 countries.

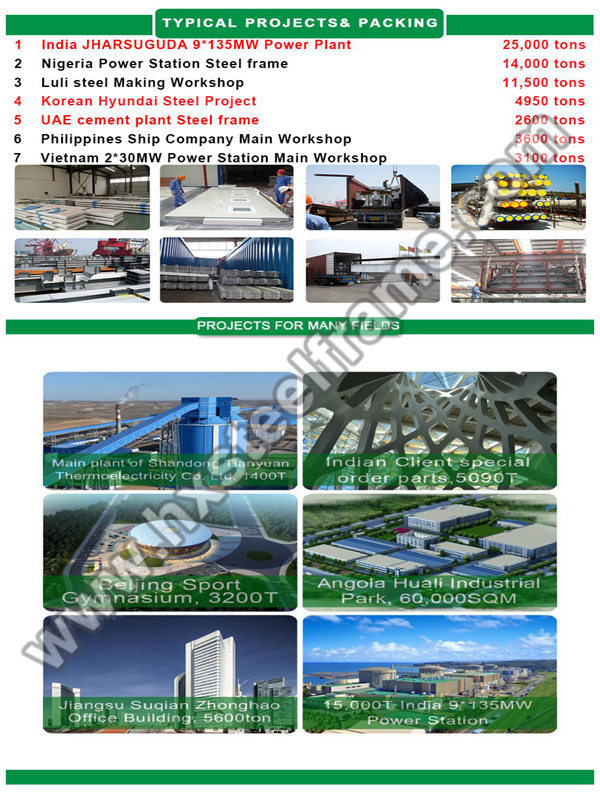

3. Project case- Angola steel structure project, 18800m2:

In 2003, Our company took over the workshop steel structure project of an Angola company, the steel structure building has been completed by now. The whole steel structure building area is 18800m2. This steel structure is particularly special, it has a certain technical difficulties. In order to carry on the project installing smoothly, Our company sent an outstanding engineer to direct the installation of the steel structure building. With 3 months hard work, we completed the project perfect finally. The customer was very satisfied with our work and gave the new steel structure workshop project drawing to us, we were excited about this. This indicates that the customer is well accepted with our steel structure production and they trust Our company. Therefore, we will work harder to make more satisfying steel structure for customers.

4. We found international surface treatment system for the prefab buildings ( made of steel frame ) :

We got NACE 1 and 2 level certificate as per American standard.

We build professional enclosed shot blasting workshop, enclosed sand blasting room, 34000m2 fully-enclosed painting workshop and 20, 000 m2 enclosed packing workshop.

5. Our seaworthy packing system for prefab buildings ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) How can I install these prefab buildings ( made of steel frame ) together as a building after cargo arrived ?

Normally, most clients choose to install the steel building structure frame themselves or ask local technical engineer for further instruction.

If local technical support is not available or cost too much, we could also provide technical support engineer cross over-seas for installation guide even with our installation engineering team.

2) How to maintain my prefab buildings ( made of steel frame ) years of using ?

prefab buildings ( made of steel frame ) are built for long-time, reliable, steady usage purpose, the maintenance process is easy to operate and complete, most our product can live 10-15 years with minimal maintenance work like gel filled and paint spray. We will keep tracking the usage performance of our products and provide maintenance instruction for our clients.