|

Shandong Huaxing Steel Structure Co., LTD.

|

metal steel buildings made of stell frame with A36 A572 steel at Uganda area

| Price: | 1000.0 USD |

| Payment Terms: | L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. 200 worker in charge of overseas construction

2. Material: steel frame, sandwich panel, Q235

3. Workshop Column: Welded or Hot rolled H-section

1. metal steel buildings ( made of steel frame ) main components :

SIZE(m) | LENGTH * WIDTH * EAVE HEIGHT |

TYPE | SINGLE SPAN , DOUBLE SPAN , MULTI - SPAN |

ONE FLOOR , TWO FLOORS , THREE FLOORS | |

BUILDING FOUNDATION | STEEL FOUNDATION WITH ANCHOR BOLTS |

COLUMN & BEAM | MATERIA L :Q235B & Q345B |

BRACING | X or V TYPE BRACING MADE BY ANGEL STEEL , ROUND Bar etc |

Wall & Roof C or Z PURLINE | SIZE :C120 ~ C320mm ; Z100 ~ Z300mm |

WALL & ROOF PANEL | SINGLE CORRUGATED STEEL SHEET |

SANDWICH PANEL INSULATION WITH EPS , PU , ROCK WOOL etc | |

WINDOW & DOOR | PVC or ALUMINIUM ALLOY WINDOW |

ELECTRIC ROOL - UP DOOR | |

SLIDING DOOR BY SANDWICH PANEL OR SINGLE CORRUGATED STEEL SHEET | |

SURFACE TREATMENT | HOT GALVANIZED COATING COLD GALVANIZING |

Spray - Painting , Any color , or according to your request | |

ACCESSIORES | SEMI - TRANSPARENT SKYLIGHT BELTS |

VENTILATORS ; DOWN PIPE ; GUTTER | |

STANDARD BOLTS |

2. About the product:

1) Product scope:

metal steel buildings ( made of steel frame ), steel structure warehouse / workshop / hangar / garage / poultry house, high rise steel building, industrial steel frame, sandwich panel, welded H steel, C/Z channel, corrugated steel sheet, etc.

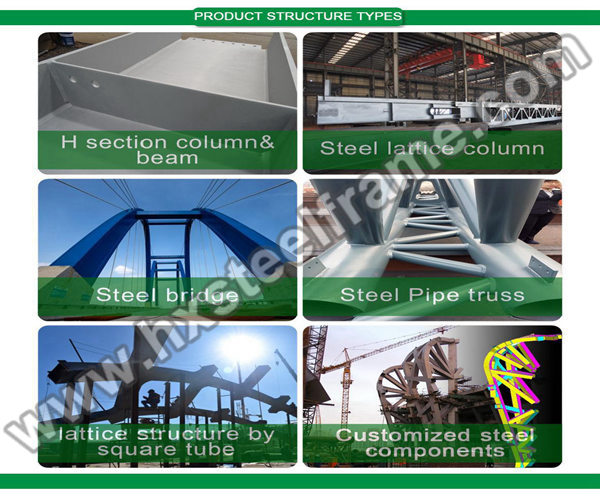

2) Products structure type& Service:

Design & fabrication & Engineering Service, Steel Building, Space Frames, lattice steel structure, Tubular Steel Structures, basic building elements( built-up welded H-section, hot-rolled H-section, channel, steel column, steel beam), standard frames, secondary framing, roof & wall materials.

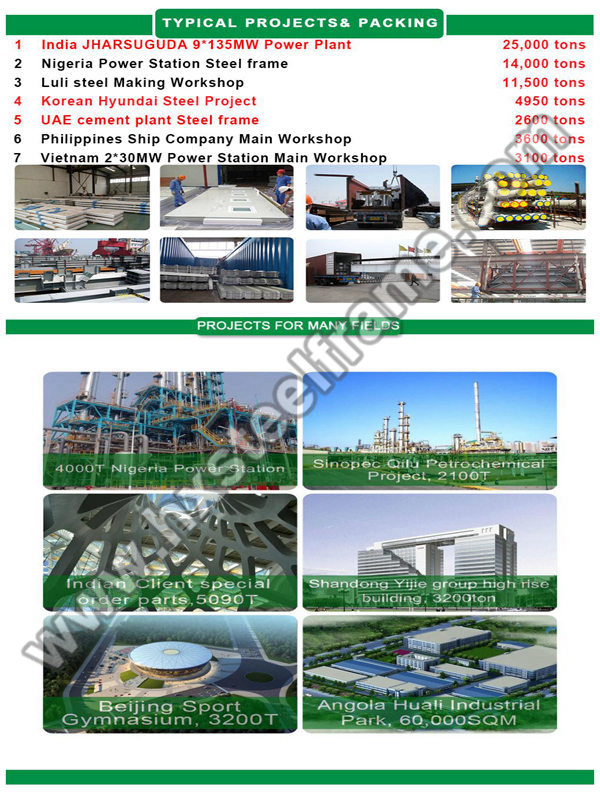

3. Project case- Heavy Steel Structure Building in Qingdao, 60, 000 SQM:

The Project - metallurgical automatic transmission equipment assembly base steel structure project. Located in Qingdao China High-tech Zone, total span is 120 meters, total length is 198.1 meters; eave height is 13.2 meters; the ridge height is 18.6 meters.

1) Trims,flashing: color steel sheet;

2) Gutter: color steel sheet;

3) Downpipe: PVC;

4) Door: sandwich panel door;

5) Window: Aluminium window( single glass)

This project is the national important investment project, the government, 3rd party QC consultant and the owner track the quality and progress very strictly in the whole process, finally they are satisfied with our quality and performance, and issue 5% extra bonus for our one month advance delivery which save them too much cost and make their production beginning earlier.

4. We found international surface treatment system for the metal steel buildings ( made of steel frame ) :

We got NACE 1 and 2 level certificate as per American standard.

We build professional enclosed shot blasting workshop, enclosed sand blasting room, 34000m2 fully-enclosed painting workshop and 20, 000 m2 enclosed packing workshop.

5. Our seaworthy packing system for metal steel buildings ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Why choose us ?

Because we are professional on the steel structure and steel building, and have the quality guarantee with the strength of design & installation.

2) How can we be sure of your products of " metal steel buildings ( made of steel frame ) " are with superior quality, as you promised?

One of the reasons for our good quality products of structural steel work is our quality inspection system which is the best of its kind.

3) Can you offer designing service for metal steel buildings ( made of steel frame ) ?

Yes, we have more than 89 design engineers. We could design full solution drawings as per your requirements. They use software: Auto CAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures( Xsteel) V16.etc.