|

Shandong Huaxing Steel Structure Co., LTD.

|

prefab steel pre engineered steel buildings Grand magnificent

| Price: | 1000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Components clearly marked according to dwg

2. Connection of steel structure: weld or bolt

3. Guarantee: The main structure over 35 to 50 years

1. Specifications of the Steel building ( made of prefab steel ) :

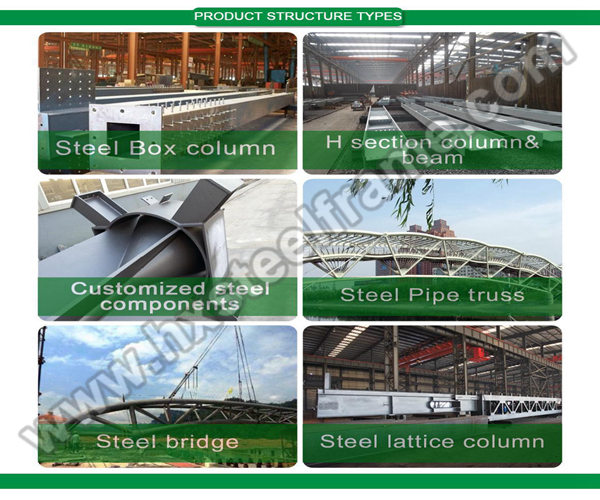

Main steel frame : | H section steel beam and columns |

Secondary frame : | Galvanized C / Z purlin , steel bracing , tied bar , knee brace , edge cover etc . |

Roof & Wall panel : | Sandwich panel , corrugated steel sheet or skylight panel |

Tie Rod : | Circular Steel Tube |

Brace : | Round Bar |

Knee Brace : | Angle Steel |

Roof Gutter : | Color Steel Sheet or galvanized Steel sheet |

Rainspout : | PVC Pipe |

Door : | Swing door , sliding door or roller door |

Windows : | PVC steel or Aluminum Alloy Window |

Connecting : | Anchor bolt , high-strength bolt , common bolt |

Drawing : | We can make the design and quotation according to your requirement or your drawing |

Installation : | Provide full set of construction drawings and video to direct installation ; Engineer are able to stay at site to direct construction |

2. Why Our Steel building ( made of prefab steel ) is your Right Choice:

1) Stable and deep financial capacity

Any investment is an important decision and should be realized through a financially stable company. Our deep community roots and stout economic strength gives us an exceptional advantage in hiring experienced professionals who will complete your project to your expectations.

2) Competitive Prices

Our production capacity(approximately 200,000 metric tons annually) together with effective and economic engineering and manufacturing methods enable us to offer the most competitive prices in the industry.

3) Fast Quotations

Quotations for simple buildings can be submitted quickly due to vast experience of our staff and the advanced design software we use.

4) Fast Delivery

We are able to design, detail, fabricate and supply simple steel buildings in approximately 4 weeks. Most of our buildings are delivered and erected within 8 weeks(this relies on various factors such as site position, weather etc).

5) Site Supervision

A site supervisor is always present at site to ensure that work is being carried out satisfactorily. Any problems that arise are quickly dealt with to minimize any delays. Safety on site is also made a priority.

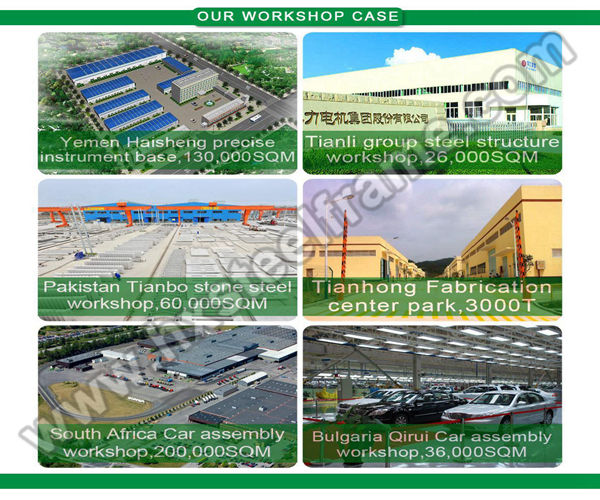

3. Project case- West Chuang Company Steel Structure Workshop / Light steel structure warehouse:

1) Roof: Color-coated Corrugated Steel Sheet with skylight panel

2) Wall: Color-coated Corrugated Steel Sheet

3) Main Steel Framework: Steel Column, Beam, Purlin and other supporting parts with shot blasting and painting process.

4) Material: Q345

5) Window: Plastic Steel Window

6) Door: Sliding Door plus Canopy(all are made by sandwich panel)

7) PVC Downpipe

8) Total 3000tons

4. Our hardware and design team strength on the Steel building ( made of prefab steel ) :

We have a number of experienced intermediate and senior technical personnel of steel structure. Our design team ensure that the stress analysis and structural calculation of all design schemes, construction drawings must be performed by professional design software, such as PKPM, 3D3S, X-Steel, Tekla, SAP2000 and AUTOCAD, etc. Therefore, the best plan can be provided to our customers efficiently and readily.

The advanced production equipment and production line ensures our production efficiency, perfect production system assures product process and quality. Our highly precise equipment including gantry planers, automatic submerged arc welding equipment, assembling machines, slitting machines, and shot blasting machines, corrugated steel sheet production line, C section steel production line, Z section steel production line, floor deck section production line, etc. We have professional QC inspectors rigorously check every stage of production to ensure only qualified products reach our customers.

5. Packaging& Shipping for Steel building ( made of prefab steel ) :

1) All the structure components, panels, bolts and sorts of accessories will be well packed with standard package suitable for ocean transport and loaded into 40' HQ.

2) All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers, who will prevent the goods to be damaged.

3) Good relationship with many vessel companies to make sure the transportation smooth.

6. FAQ:

1) Would you send engineers to the site to guide for working when installed ?

Re: Yes, Usually we will send two engineers to the site, and the cost shall be in the customer account.

2) Can you design for Steel building ( made of prefab steel ) ?

Re: Sure, we have excellent design team, our mainly design software are Auto CAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures( Xsteel) V12.0.etc

3) Are you a factory, Can we visit your factory ?

Re: Yes, We are a professional manufacture of steel structure factory which has better cost advantage than trading company. Welcome you to visit our company.