|

Shandong Huaxing Steel Structure Co., LTD.

|

standard structural steel sections and construction steel frame export to Oman

| Price: | 1000.0 USD |

| Payment Terms: | L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Sandwich panels covered with plastic film

2. Strong anti-vibration( earthquake)

3. We are an ISO 9001: 2000 certified company

1. Technical parameters for Steel building ( made of standard structural steel sections ) :

Size | According to customer's requirements |

Standard | GB , DIN , JIS , BS , ASTM |

Material | Q235 ; Q345 |

Surface treatment | Painted with epoxy paint or zinc rich paint |

Package | In bundle or pallet or according to the requirements of customers |

Delivery | Container or Bulk |

Shipment Time | According to the quantity and specification of each order |

Production Usage | Used in industrial or civil fields |

Product Characteristics | 1 . Fine gloss exterior , anti-corrosive 2 . High strength , satisfactory property of the steel 3 . Anti-seismic , wind resistance , environmental protection 4 . Fire- resistant , clean and health 5 . 50-year-long life expectancy |

Remark | Payment terms : T/T, L/C |

Terms of trade | FOB , CFR , CIF , EXW |

2. Who we are:

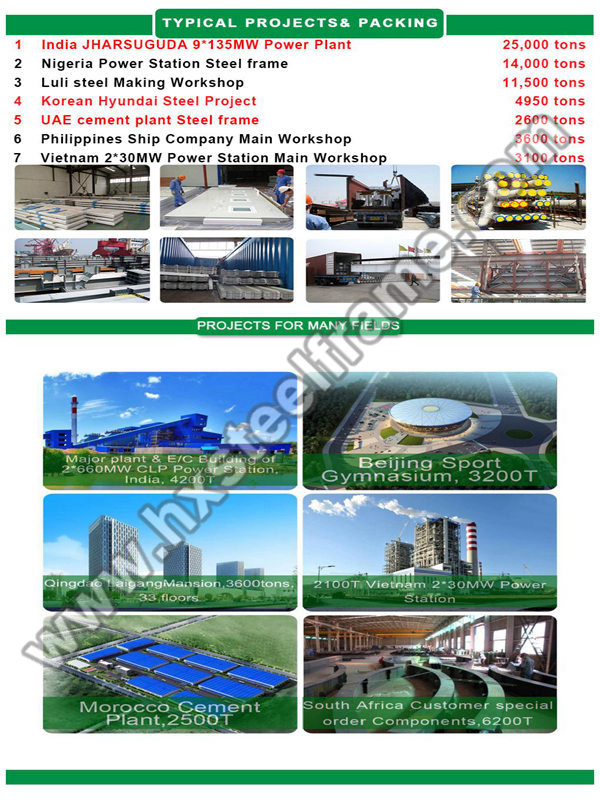

We are mainly specially steel structure construction company undertaking the design, fabrication, assembly, and after-sales service of various types of Steel building ( made of standard structural steel sections ), civil construction, heavy steel structures, stadiums, industrial workshops and warehouse building, steel structures high-rise building.

Now we have 3 heavy steel production line, six light steel production lines, 3 H-beam secondary processing lines, and advanced digital-controlled multi-head cutting machine,automatic submerged arc welding machine, assembly machine, calibrating machines, full-automatic shot blasting machines, totaling 200 equipment or more.

3. Project case- Singapore Ship Manufacturing Yard, 1100ton:

Detailed introduction

Location: Singapore

Tonnage: 1100ton

Structure Type: 40m x150m, lattice column and truss girder with 30MT crane capacity.

Function: Ship Manufacturing/ Repair Yard

Execution: Feb 2011~ April, 2013

This client pay much attention on the product surface quality, after they check our welding like quality and the smooth surface after painting, they made the decision to work with us without any hesitation.

Our good surface quality is due to we found international surface treatment regulation for many years.

We got NACE 1 and 2 level certificate as per American standard. We build professional enclosed shot blasting workshop, enclosed sand blasting room, 34000M2 fully-enclosed painting workshop and 20,000 SQM enclosed packing workshop.

4. We found international surface treatment system for the Steel building ( made of standard structural steel sections ) :

We got NACE 1 and 2 level certificate as per American standard.

We build professional enclosed shot blasting workshop, enclosed sand blasting room, 34000m2 fully-enclosed painting workshop and 20, 000 m2 enclosed packing workshop.

5. Our seaworthy packing system for Steel building ( made of standard structural steel sections ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) How about the derust grade of your Steel building ( made of standard structural steel sections ) ?

Reply: Ball blasting Sa2.5 on main steel structure or by Galvanized frame;

manual derust St2.5 on secondary steel structure.

2) What kind of panel used for the roof and wall ?

Reply: Color corrugated steel sheet and sandwich panel could be used. Sandwich panel performs well on the heat insulation, sound insulation. Common sandwich materials are EPS, glass wool and PU sandwich panels.

3) Are Steel building ( made of standard structural steel sections ) expensive ?

Answer: The steel structure of our company is economic. Its technology and materials used decreases waste expenses such as wood, decorative stone, brick etc. All the material including the steel frames, wall body and roof for installation are prefabricated during the production process, therefore the labor costs for installation is decreased.