|

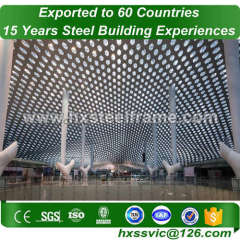

Shandong Huaxing Steel Structure Co., LTD.

|

offshore steel structures formed new steel buildings with fashionable outlook

| Price: | 1000.0 USD |

| Payment Terms: | L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. 200 worker in charge of overseas construction

2. AWS& EN welder, CE, ensure production quality

3. High quality welding process are used

1. Technical specifications of Steel building ( made of offshore steel structures ) :

Steel building ( made of offshore steel structures ) is an pre-engineered steel structure which is formed by the main steel framework linking up H section , Z section , and C section steel components, roof and walls using a variety of panels . The steel frame is widely used for the large-scale workshop , warehouse , office building , steel shed , aircraft hangar etc.

Technical parameters | Main steel structure | welded H steel |

Column and Beam | Welding H section steel | |

Purlin | C or Z section steel | |

Wall and Roof insulation | Single colour sheet , Colour sheet with Glass-wool , EPS Sandwich panel , for customers choose | |

Crane | 5T , 10T , 15T , etc . | |

Door | 1 Sliding Door 2 Swing door 3 roll-up door | |

Window | Aluminum Window | |

Brace | round steel | |

Lateral and column bracing | round steel | |

Knee brace | hot- rolled angle steel | |

Trims , flashing | color steel sheet | |

Gutter | color steel sheet | |

Downpipe | PVC | |

Tie bar | round tube | |

Engineering Design Software | AutoCAD , PKPM , MTS , 3D3S , Tarch , Tekla Structures ( Xsteel ) V12.0. etc | |

Certificate | ISO9001 : 2000 ; ISO14001 : 2004 and OHSAS18000 | |

2. Why choose us as your steel structure supplier:

Founded in Shandong province, we are a professional manufacturer of steel structure building, workshop, warehouse, high rise building, industrial steel structure, civil steel structure, sandwich panel and profiled steel with ISO9001, SGS and CE certification.

We once made 30, 000 SQM prefabricated building in 16 days for a major buyer in Saudi Arabia. And, we manufactured 200, 000 square meter of prefabricated steel building monthly for post-Wenchuan Earthquake reconstruction. Our daily capacity is large 5, 0000 square meter and this is how we manage it:

1) 200, 000 square meter of factory space

2) 10 production lines for our prefabricated building series, 960 workers

3) 200 workers in charge of overseas construction

4) Our sales representatives can reply to your inquiries within eight hours in English, French and Japanese.

5) Two hundred workers oversee overseas construction.

6) We passed quality tests by India Adani Power, Hyundai Steel, China Construction Group, China Railway Construction Group and other biggest companies in the world.

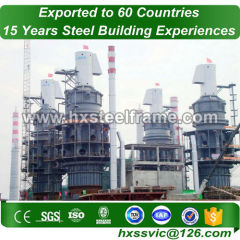

3. Project case- 10000 tons heavy steel structure for Indian cement plant Project:

Description:

The whole steel consumption of this is more than 10000 tons, Among which, the steel consumption of steel roofing truss for steel structure homogenization silo and structural steel bunker is about 7000 tons.

Raw materials silo, clinker materials silo, electricity dust removal, pre-heater and other structures, together with steel structure buildings for subsidiary equipment, total steel structure components reach approximately 3, 000 tons.

4. We found international surface treatment system for the Steel building ( made of offshore steel structures ) :

We got NACE 1 and 2 level certificate as per American standard.

We build professional enclosed shot blasting workshop, enclosed sand blasting room, 34000m2 fully-enclosed painting workshop and 20, 000 m2 enclosed packing workshop.

5. Our seaworthy packing system for Steel building ( made of offshore steel structures ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) How about the derust grade of your Steel building ( made of offshore steel structures ) ?

Reply: Ball blasting Sa2.5 on main steel structure or by Galvanized frame;

manual derust St2.5 on secondary steel structure.

2) What kind of panel used for the roof and wall ?

Reply: Color corrugated steel sheet and sandwich panel could be used. Sandwich panel performs well on the heat insulation, sound insulation. Common sandwich materials are EPS, glass wool and PU sandwich panels.

3) Are Steel building ( made of offshore steel structures ) expensive ?

Answer: The steel structure of our company is economic. Its technology and materials used decreases waste expenses such as wood, decorative stone, brick etc. All the material including the steel frames, wall body and roof for installation are prefabricated during the production process, therefore the labor costs for installation is decreased.