|

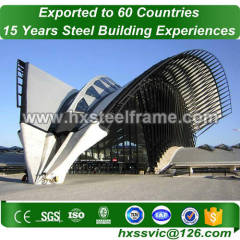

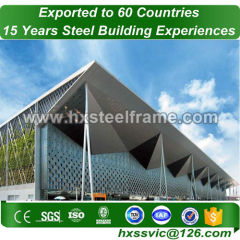

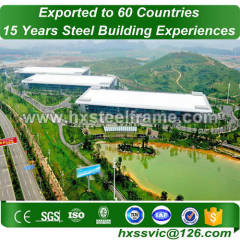

Shandong Huaxing Steel Structure Co., LTD.

|

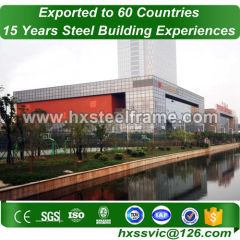

modular prefabricated buildings and custom metal buildings china good selling

| Price: | 1000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Number of Architectural Designers: 58

2. Connection of steel structure: weld or bolt

3. Foundation connected by anchor bolt

1. Design parameters of the modular prefabricated buildings ( made of steel frame ) need to be provided :

1) Live load on roof ( KN/M2 ) |

2) Wind speed ( KM/H ) |

3) Snow load ( KG / M2 ) - If Applicable |

4) Crane ( if you have ) , Crane span , Crane lift height , max lift capacity , max wheel pressure and min wheel pressure |

5) Size : width X length X eave height , roof slope |

6) Or your idea ! |

BUT maybe you are unsure about what type or what needs you have regarding your warehouse / workshop , or this project is your first one . Don't worry , we will teach you to choose the right style and the finest design within your budget . |

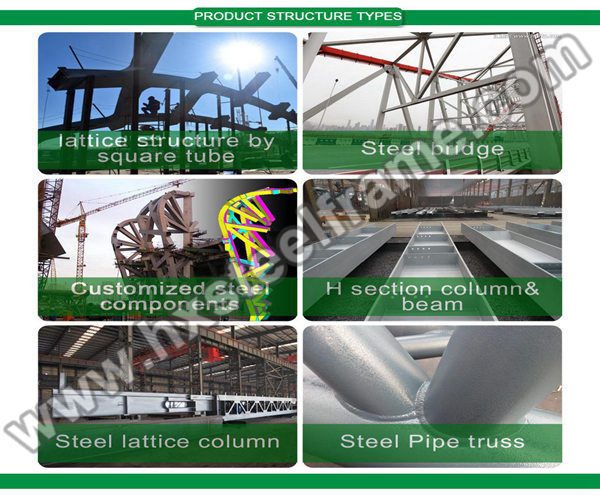

2. We supply both common steel building and the special steel structure:

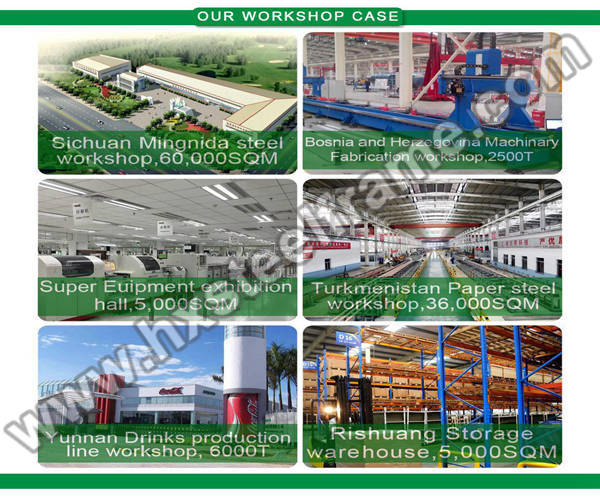

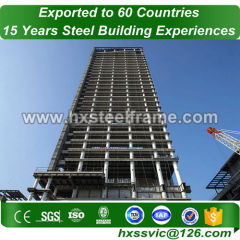

Besides structural steel building like workshop, warehouse, high rise building, modular prefabricated buildings ( made of steel frame ) etc, we can also do nonstandard structural steel member fabrication according to client' s sample or drawings, like special shape structures, board girder, industrial steel frames, belt conveyor and other supporting frames, steel gallery, reclaimer and deck parts etc.

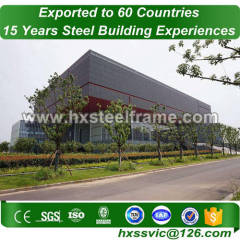

3. Project case- Description of Hengda steel structure workshop building:

The axis area for this steel structure workshop building is 19578m2

Axis dimension is 180m, 108m, the eave height is 14.15meters.

The primary member is Q345B, all are sand-blasting,

The surface treatment quality required meets GB 8923 SA 2 1/2 Grade

Painting is two coats of anti-corrosive primer and two alkyd finish

Crane runway girder is equipped in each span, install 32mt and 16mt overhead crane

4. We can provide shop and installation drawing for modular prefabricated buildings ( made of steel frame ) :

1) After reaching a contract, we will carry out a detailed design in terms of the structural drawing and architectural drawing, build a three-dimensional model system by Tekla Structures( Xsteel) , and work out the shop drawing of each component efficiently and accurately. This not only can benefit future precise manufacturing but also can avoid component collision during construction in later stage.

2) We produce according to the process drawing and make delivery according to the shipping list.

3) We provide a complete set of installation drawings. If the customer has requirements, we can provide installation guiding services.

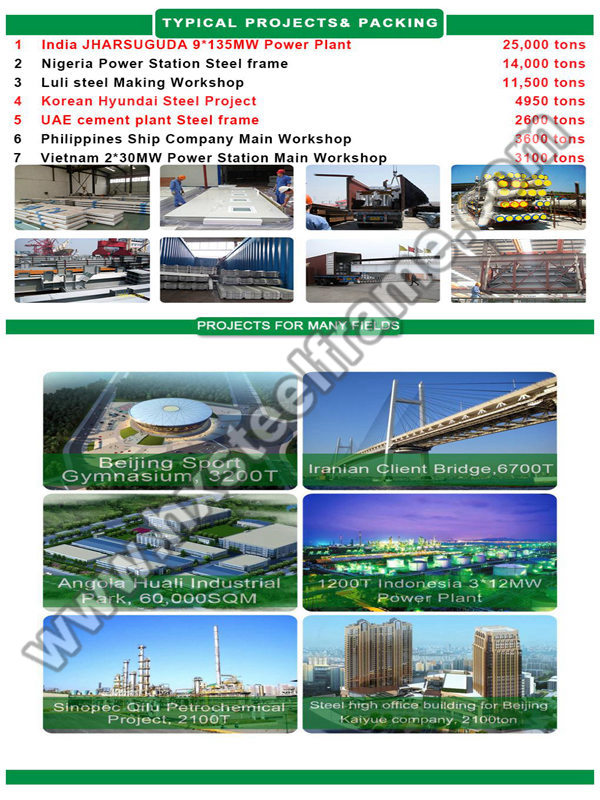

5. Our seaworthy packing system for modular prefabricated buildings ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Why I should choose your company ?

A: Firstly, we are the real factory, all range of steel structure products are manufactured on our production line. Now we already have two production base, we can guarantee our product and ensure the delivery time. We can manufacture the products which meet your special demand and we will do everything in our power to turn out the satisfaction to you. Secondly, we have professional foreign trade team with high efficiency communications and we can give you professional solutions. We will work hard and strive towards our service concept of " Zero-Defect Quality, Zero-Distance service and Zero-Complaint Service ". Thirdly, we have good business relationship with our partners and we have extends business to over thirty countries in Western Europe, Southeast Asia, Africa and South America. We will keep researching and developing, to provide more and more excellent products and perfect service to all customers.