|

Shandong Huaxing Steel Structure Co., LTD.

|

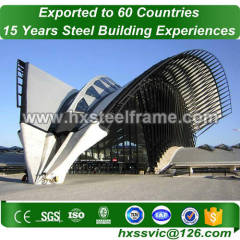

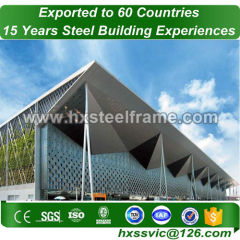

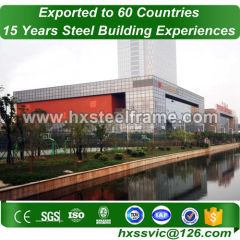

pre constructed buildings and custom metal buildings hot Sell sale to Luanda

| Price: | 1000.0 USD |

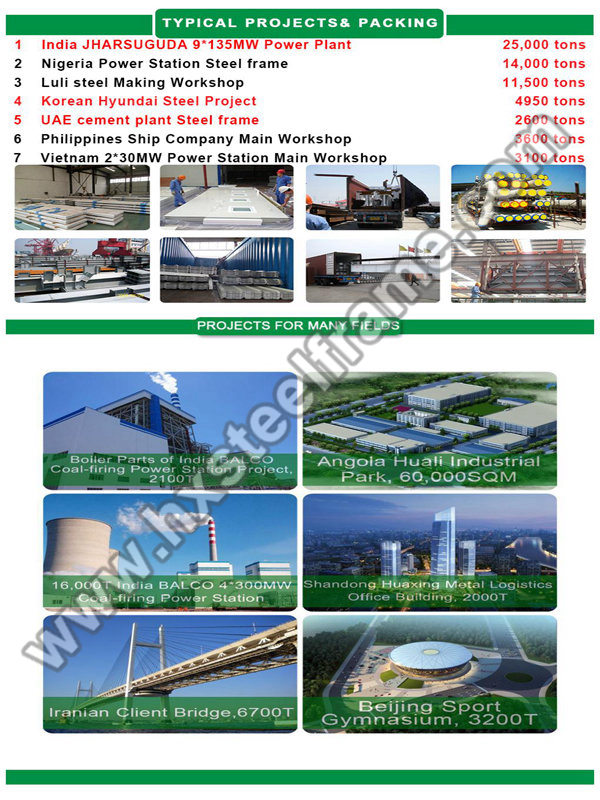

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. 300 sets of advanced processing equipment

2. Scope: warehouse, workshop, poultry shed etc

3. Building Type: warehouse, workshop, Agricultural

1. Data of the pre constructed buildings ( made of steel frame ) :

Specification | |

Material : | Grade Q235 , equivalent to ASTM A36 Grade Q345 , equivalent to ASTM A572 |

Section : | Any product shape according to customer's requirements |

Certification : | ISO quality system , Chinese GB50221 - 2001 |

Sand Blast : | SA 2.5 Sand blasting |

Welding Technology : | Single level butt welding , fillet welding by electric arc welding , and Gas shielded welding |

Surface treatment : | Hot dip galvanized , Epoxy zinc rich primer Standard : ISO1461 ( 1999 ) , JIS H 8641 - 1999 , ASTM A 123 / A 123M-02 |

Welding Testing | Ultrasonic Testing , X-ray Testing |

Manufacturing Technology | Drilling , Cutting , Assembling , Welding , Rectification , Testing etc |

2. Wide Fields of Steel Structure be used:

1) Industrial steel structure warehouse, pre constructed buildings ( made of steel frame )

2) Steel workshop / hangar / garage

3) prefabricated steel structure shed, Exhibition Hall, Office buildings

4) Garage, Musty-story building, Agricultural storage

5) Logistic centers and all kinds of steel structure buildings etc

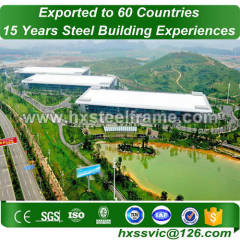

3. Project case- warehouse construction for Brazil Hidu logistics Park, 2014, 19, 200SQM:

Warehouse size is 160m length* 120m width* 15m height. Because the schedule is very tight, the contractor require to be completed within one month. Our company try our best to only use 25 days finish the project. Get government and Hidu Group highly praise.

Technical specification:

1) Column spacing: 6 m

2) Steel column: Q345, H500 * 200 * 10 * 12( GB)

3) Steel beam: Q345, H( 300-600) * 200 * 8 * 12( GB)

4) Roof purlin: C160 * 60 * 20 * 2.3( GB)

5) Wall purlin: C160 * 60 * 20 * 2.3( GB)

6) Column bracing: 25 steel round

7) Horizontal bracing: 25 steel round

8) Gutter water system: 3mm steel sheet, 160 PVC downpipe

9) Roof panel( outside): V-760, 0.5mm single board+ 75mm fiberglass+ aluminum foil

10) Wall panel: V-820, 0.5mm single board

11) Components paint: main structure sprayed 3 times, secondary frame for 2 times with iron red acrylic anti-rust paint and a medium gray alkyd primer

The client hired the SGS as the 3rd party QC, all WPS and QAP are adopting the highest international standard. We perfectly finish this project and won the trust of the client. Client told us, this is the real win-win business. Because we help them win the trust and profit from the owner due to our quick delivery with best quality.

4. Our engineer team for pre constructed buildings ( made of steel frame ) :

We owns 36 TEKLA professional designers, by applying computer work station.

They make the model for steel structure items assembling, define the assembly dimension and inspect the connection status of each joint in three-dimensional way through difference perspectives,

which has optimized the design for realizing 100% successful bolt installation, greatly enhancing working efficiency.

We owns 15 professional STAAD-Pro designers.

As for secondary design and partition treatment of drawings, our design team applies STAAD-Pro together with Ram Connection module to optimize joint design to establish scientific and reasonable assembly design scheme.

5. Our seaworthy packing system for pre constructed buildings ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Are you manufacturer or trader ?

We are manufacturer. Welcome to visit us at any time!

2) How can you avoid size error in supplying us the pre constructed buildings ( made of steel frame ) ?

We select international size error standards;

Use specified equipment to cut shear and rectify steel plate according to steel thickness;

Standard weld and installation order to lessen deformation.

3) What is the cost if we ask your engineers to assemble ?

Round-trip air tickets, eating, living, translation fee, visa fee and salary.

Our team include senior engineers with professor titles, first-class registered constructors, first-class registered structural engineers, first-class registered cost engineer, registered architect, American CWI engineer, EN TWI engineer, EN IWE welding engineer, American NACE painting engineer and various technicians with senior and medium professional titles.