|

Shandong Huaxing Steel Structure Co., LTD.

|

pre engineered construction and custom metal buildings with CE at Cairo area

| Price: | 1000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Exporte to Philippines, Malaysia, Australia

2. Door for workshop: Rolled up or Sliding door

3. Products passed through strict quality checks

1. Characteristics of pre engineered construction ( made of steel frame ) :

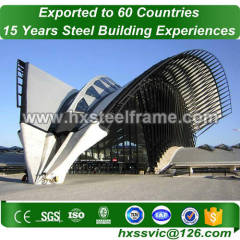

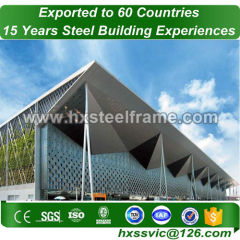

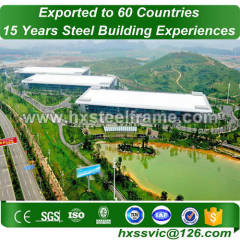

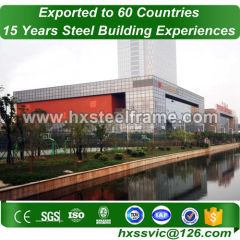

Steel structure is widely used as warehouse , factory , hotel , church , garage etc . It is durable , economic and environmental .

Main Grade : Q345B , Q235B

Standard : ISO9001 : 2008

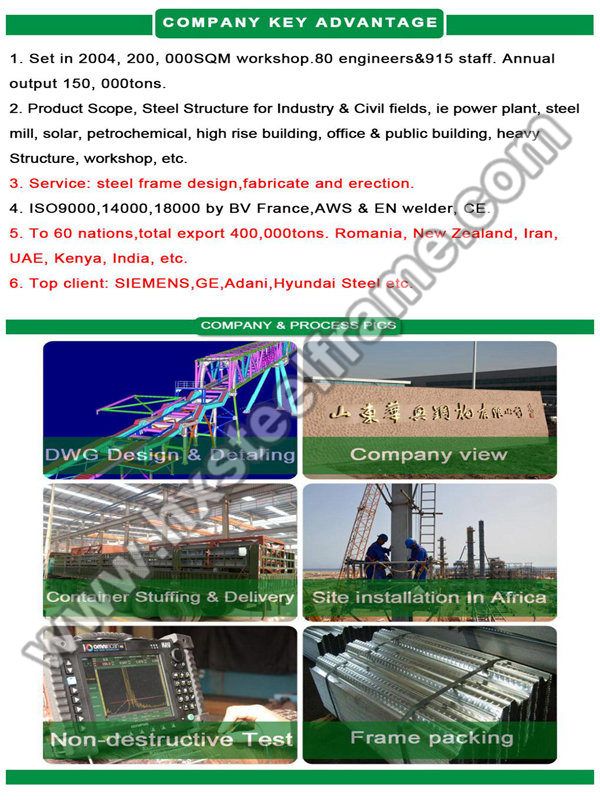

We are a Factory-direct provider of all kinds of steel structure buildings and material plant . We specialize in design , fabricate construction , install and related technology guide . Our competitive price and high quality have got customers from all over the word .

Applications :

Used as Steel workshop / warehouse / shed , Exhibition Hall , Office buildings , Garage , Multi-story building , Hanger , Agricultural storage , Logistic centers , and all kinds of steel materials etc .

Specifications :

Main Steel : Q345B , Q235B

Column&Beam : Welded or Hot rolled H-section

Wall&Roof : EPS , Rock wall , PU sandwich , corrugated steel sheet

Door : Rolled up door or Sliding door

Window : Plastic steel or Aluminum alloy window

Surface : Hot dip galvanized or painted . ( all colors we can do )

Crane : 5T , 10T , 15T , etc .

2. Our Products Scope:

1) Steel Structure for industrial and power fields, such as power plant, steel mill, solar industry, hydroelectric plant, petrochemical fields, oil and gas pipeline, etc.

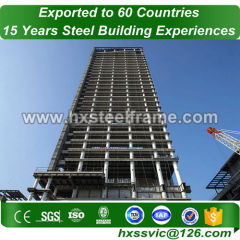

2) Steel Structure for civil fields, like high-rise building, heavy Steel Structure, workshop& warehouse, etc.

3. Project case- Qilu Petro-chemical Heavy Steel Workshop:

Size: 55000 square meter workshop, Single Span 39m, eave height 18m, mainly loading bear steel member over 100Ton, totally quantity of steel 6000Ton.

Steel Column: Q345B Four tube lattice column. Painted: 120um epoxy zinc painted.

Roof Structure: Q235B Pipe Truss Structure. Painted: 120um epoxy zinc painted.

Crane Beam: Q345B H section Steel Beam. Painted: 120um epoxy zinc painted.

Secondary Structure

Roof Horizontal Bracing: Q235B Angle Steel, Painted: three layer white color anti-rust Alkyd painted

Wall X Cross Bracing: Q235B Double Angle Steel, Painted: three layer white color anti-rust Alkyd painted

Tie Beam: Q235B Welding Pipe, Painted: three layer white color anti-rust Alkyd painted.

Roof Purlin: Galvanized C section steel

Wall Purlin: Galvanized C section steel

Steel Rod: Galvanized Steel Rod.

Panel system

Roof: 0.5mm Single Color sheet

Wall: 0.5mm Single Color sheet

4. Our company' s design and quotation capability for pre engineered construction ( made of steel frame ) :

1) We make visual architectural drawings and 3D effect drawings according to customers' demand, enabling customers to see the products they desire clearly. Therefore, the best plan dwgs can be sent to customers efficiently.

2) After deciding the scheme, we will begin to design the building structure. We will carry out stress analysis and structural calculation through " 3D3S " and " PKPM ". Then we conduct secondary optimization of the scheme based on calculation report, and ensure the safety performance of building structure with the most reasonable steel quantity and connection method.

3) After designing the structure, our quotation specialist will make the engineering material bill according to structural design drawings, and provide the final engineering quotation list after referring and adjusting to the material price information on the market.

5. Our seaworthy packing system for pre engineered construction ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Q: How could I control the cost of building a pre engineered construction ( made of steel frame ) ?

A: Firstly, the designing scheme should be mutually discussed and then accepted. Then, the kinds of building materials should be confirmed since different types and qualities make various prices. After that, we will send you a detailed quotation.

2) Q: How Long does it take to build a pre engineered construction ( made of steel frame ) ?

A: It depends on the size of the warehouse. Generally, the construction period of is 1 month of a 2000-square-meter workshop by a construction team of 8-10 people. It only costs 2-3 weeks to build the steel structure frame.

3) Q: Is it difficult to build a pre engineered construction ( made of steel frame ) ?

A: totally not, you can let your local teams build it according to the construction drawings and erection guiding video provided by us.