|

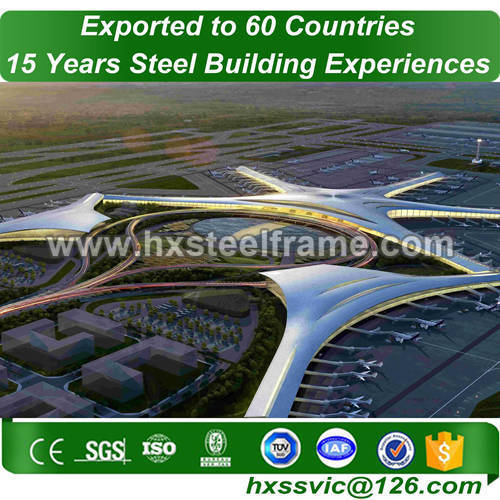

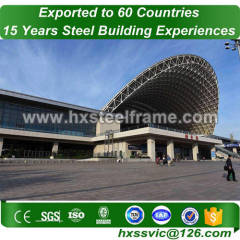

Shandong Huaxing Steel Structure Co., LTD.

|

big steel buildings made of built-up steel column cost-saving export to Banjul

| Price: | 1000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Shipping depended on order quantity

2. Material: steel frame, sandwich panel, Q235

3. With ISO9001, CE and SGS approval.

1. Typical Surface treatment for big steel buildings ( made of steel frame ) :

Surface Treatment |

Hot dip galvanize |

Standard : JIS , DIN , ASTM B695 - 2000 |

Hot dip galvanizing hole cutting good looking on surface |

Galvanizing process : Steel structural components → Degreasing → Rinsing→ Pickling → Rinsing → Fluxing → Galvanizing → Quenching → (Passivation) → Inspecting → Finished Product |

Paint |

1 . Primer paint one coat 20 - 30 um |

2 . Middle paint two coat 40 - 60 um |

3 . Finish paint one coat 20 - 30 um Paint type : 1 . red primer 2 . zinc primer 3 . Alkyd primer |

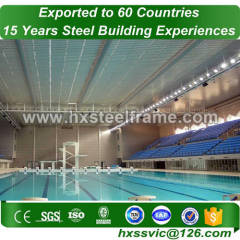

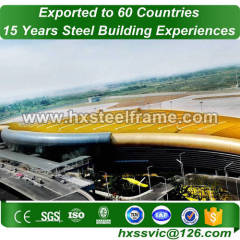

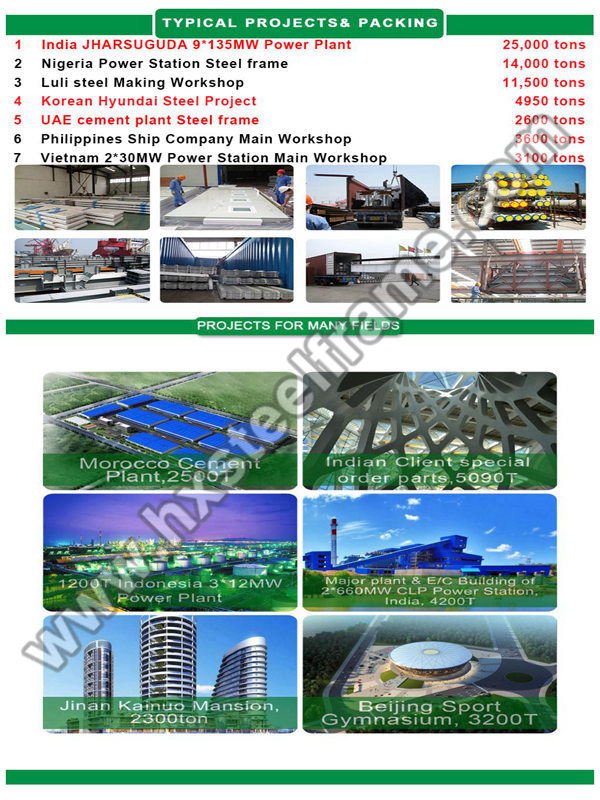

2. China Steel Structure Solution Leader :

310+ Projects/ 40+ Countries/ 300,000 MT Exported

American& European Certification System

We could fabricate all kinds of steel structure for industrial and civil fields, like Power Plant [ Incl. HRSG( NPP) & Ducts; ACC; Conveyor], Oil Gas & Chemicals, Metal & Mining, Commercial Building, steel workshop, high rise building, Theme Park, Modularization and Fireproofing, etc.

3. Project case- Qilu Petro-chemical Heavy Steel Workshop:

Size: 55000 square meter workshop, Single Span 39m, eave height 18m, mainly loading bear steel member over 100Ton, totally quantity of steel 6000Ton.

Steel Column: Q345B Four tube lattice column. Painted: 120um epoxy zinc painted.

Roof Structure: Q235B Pipe Truss Structure. Painted: 120um epoxy zinc painted.

Crane Beam: Q345B H section Steel Beam. Painted: 120um epoxy zinc painted.

Secondary Structure

Roof Horizontal Bracing: Q235B Angle Steel, Painted: three layer white color anti-rust Alkyd painted

Wall X Cross Bracing: Q235B Double Angle Steel, Painted: three layer white color anti-rust Alkyd painted

Tie Beam: Q235B Welding Pipe, Painted: three layer white color anti-rust Alkyd painted.

Roof Purlin: Galvanized C section steel

Wall Purlin: Galvanized C section steel

Steel Rod: Galvanized Steel Rod.

Panel system

Roof: 0.5mm Single Color sheet

Wall: 0.5mm Single Color sheet

4. Our Design Software adopted for big steel buildings ( made of steel frame ) :

We use a series of advanced computation, analysis, design software, and dwgs detailing& mapping software, it including American SAP2000, American STAAD-Pro connection calculation software, Korean Midas gen software of finite element analysis, PKPM, 3D3S, Finland Xsteel, and AUTOCAD, etc.

We use computer workstation to Build 3D model, optimize the design scheme, which increase the product accuracy and material use ratio effectively.

5. Our seaworthy packing system for big steel buildings ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Why choose us ?

Because we are professional on the steel structure and steel building, and have the quality guarantee with the strength of design & installation.

2) How can we be sure of your products of " big steel buildings ( made of steel frame ) " are with superior quality, as you promised?

One of the reasons for our good quality products of structural steel work is our quality inspection system which is the best of its kind.

3) Can you offer designing service for big steel buildings ( made of steel frame ) ?

Yes, we have more than 89 design engineers. We could design full solution drawings as per your requirements. They use software: Auto CAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures( Xsteel) V16.etc.