|

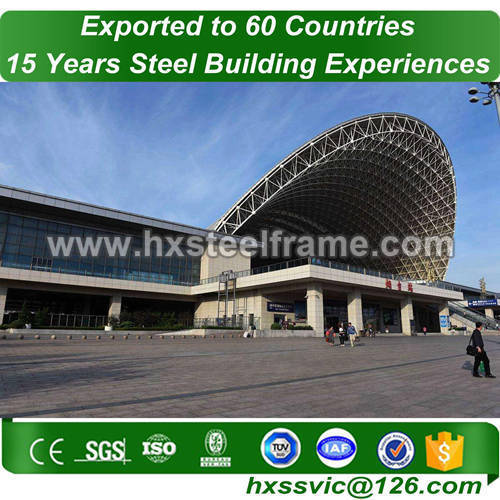

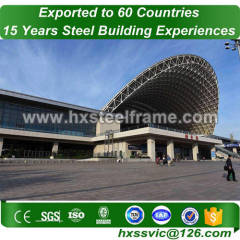

Shandong Huaxing Steel Structure Co., LTD.

|

clearance steel buildings and steel building kits hot Sell for Belgrade client

| Price: | 1000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Windows protected by the bubble papers

2. SGS, BV and other test are available for us

3. Lead Time: Within 20days after receive deposit

1. clearance steel buildings ( made of steel frame ) products description :

Dimensions | Length | H beam : 4000 - 15000mm |

Thickness | web plate : 6 - 32mm wing plate : 6 - 40mm | |

Height | 200 - 1200mm | |

Color | Depend on customers' needs | |

Advantages | 1 . Design according to customers' requirements | |

2 . Manufacture under complete quality control system --- ISO9001 | ||

3 . Installation with instruction of experienced engineers | ||

4 . Easy to assemble and dismantle | ||

5 . Eco-friendly material: can be used for several times and recyclable | ||

6 . Short construction period , long using time | ||

7 . High strength and stiffness , high weight bearing. | ||

8 . Sound insulation and heat insulation ; antisepsis and damp proofing ; waterproof and aseismatic | ||

Main components | Main frame | H beam |

Purlin | C or Z section steel purlin | |

Brace | Anchor , ordinary , high strength bolt | |

Bolt | Sandwich panel or steel plate | |

Roof &wall | PVC or aluminum alloy door | |

Door | Sliding or rolling door | |

Insulation panel | EPS , Rock wool , PU sandwich | |

Material | Q235B Q345B China standard steel | |

Sheet | 0.5mm or 0.6mm galvanized sheet | |

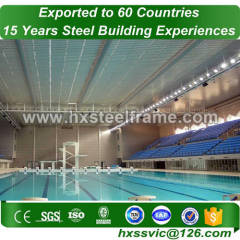

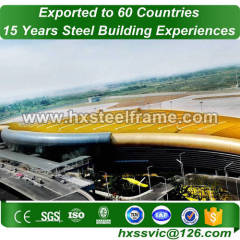

2. Wide Fields of Steel Structure be used:

1) Industrial steel structure warehouse, clearance steel buildings ( made of steel frame )

2) Steel workshop / hangar / garage

3) prefabricated steel structure shed, Exhibition Hall, Office buildings

4) Garage, Musty-story building, Agricultural storage

5) Logistic centers and all kinds of steel structure buildings etc

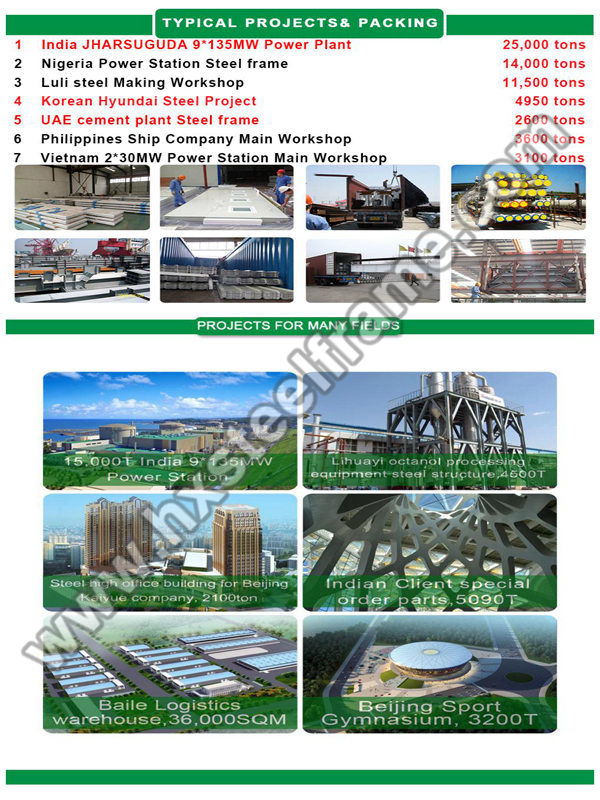

3. Project case- Congo Hebe Fabrication Petro-chemical Plant Module:

Product Description

Type 1 steel warehouse( 2500 m2) details:

A. Length: 130m

B. 10 meters between the 7 main frames

C. Height: 10 meters inside

D. Slope for roof: 23%

E. Aluminium panels for Roof with 35um coating thickness

F. 10T Overhead bridge Crane( also known as dual-beam bridge / gantry crane bridge

G. The Congo client need the side walls( only 3 sides) , for the 4th side, quoting a self collapsing gate

4. Our engineer team for clearance steel buildings ( made of steel frame ) :

We owns 36 TEKLA professional designers, by applying computer work station.

They make the model for steel structure items assembling, define the assembly dimension and inspect the connection status of each joint in three-dimensional way through difference perspectives,

which has optimized the design for realizing 100% successful bolt installation, greatly enhancing working efficiency.

We owns 15 professional STAAD-Pro designers.

As for secondary design and partition treatment of drawings, our design team applies STAAD-Pro together with Ram Connection module to optimize joint design to establish scientific and reasonable assembly design scheme.

5. Our seaworthy packing system for clearance steel buildings ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) How about the derust grade of your clearance steel buildings ( made of steel frame ) ?

Reply: Ball blasting Sa2.5 on main steel structure or by Galvanized frame;

manual derust St2.5 on secondary steel structure.

2) What kind of panel used for the roof and wall ?

Reply: Color corrugated steel sheet and sandwich panel could be used. Sandwich panel performs well on the heat insulation, sound insulation. Common sandwich materials are EPS, glass wool and PU sandwich panels.

3) Are clearance steel buildings ( made of steel frame ) expensive ?

Answer: The steel structure of our company is economic. Its technology and materials used decreases waste expenses such as wood, decorative stone, brick etc. All the material including the steel frames, wall body and roof for installation are prefabricated during the production process, therefore the labor costs for installation is decreased.