|

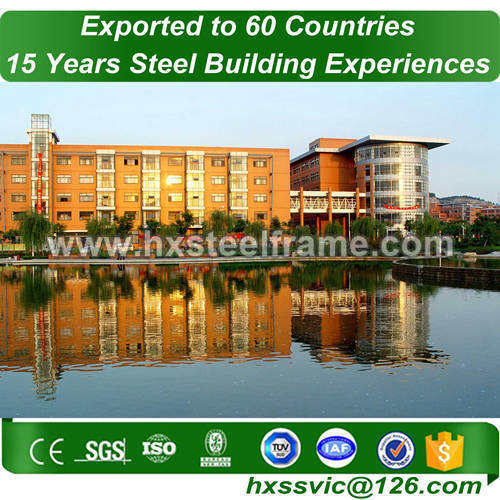

Shandong Huaxing Steel Structure Co., LTD.

|

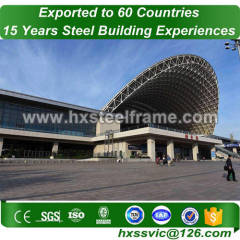

crown steel buildings and steel building kits hot-galvanized sale to Peru

| Price: | 1000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

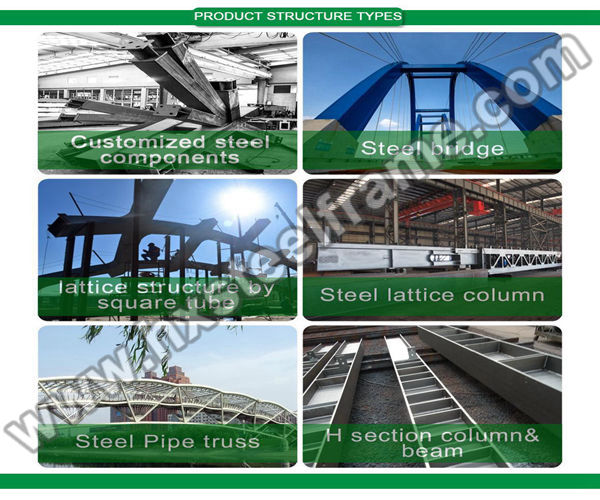

1. Pass approval of ISO, CE, ASME, CWI, SGS, BV

2. Scope: warehouse, workshop, poultry shed etc

3. Our products have been export to 50 countries

1. Typical Surface treatment for crown steel buildings ( made of steel frame ) :

Surface Treatment |

Hot dip galvanize |

Standard : JIS , DIN , ASTM B695 - 2000 |

Hot dip galvanizing hole cutting good looking on surface |

Galvanizing process : Steel structural components → Degreasing → Rinsing→ Pickling → Rinsing → Fluxing → Galvanizing → Quenching → (Passivation) → Inspecting → Finished Product |

Paint |

1 . Primer paint one coat 20 - 30 um |

2 . Middle paint two coat 40 - 60 um |

3 . Finish paint one coat 20 - 30 um Paint type : 1 . red primer 2 . zinc primer 3 . Alkyd primer |

2. Why choose us:

1) Workshop covers an area of 200, 000 square meters;

2) Owning 10 professional production lines, annual output reaches 150, 000tons for all kinds of crown steel buildings ( made of steel frame )

3) More than 80 senior & middle rank engineers; .

4) Products pass the approval of ISO9001, CE, ASME, CWI, SGS, BV etc;

5) Products have already exported to Philippines, Malaysia, Australia, the United States, Chile, the United Arab Emirates, Saudi Arabia, Russia, Niger etc more than 60 countries and regions.

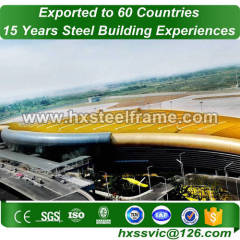

3. Project name: Pakistan Ceramic Tile Factory, 2015, 49050 m2:

Location: Pakistan

Area: 49050m2

Project time: the year of 2015

This workshop is used for ceramic tile production, all use steel frame with an area of 49050 m2. Main materials are as following:

Steel truss: Q345B

Column: Q345B

Roof & wall purlin: galvanized Z280X75X20X2.5

Horizontal bracing: 25 round steel

Wall cladding: corrugated steel sheet+glass wool+corrugated steel sheet

Roof cladding: corrugated steel sheet+glass wool, skylight panel, ventilator

Door: electric rolling door, electric sliding door

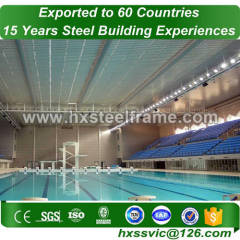

4. DESIGN STANDARD& SOFTWARE for crown steel buildings ( made of steel frame ) :

Standard: America Standard, Australia Standard, England Standard, China Standard, etc.

Software: SAP2000, Auto CAD, PKPM, RSTAB, PROE, MTS, Tekla Structures( Xsteel) , 3D3S, Tarch, etc.

5. Our seaworthy packing system for crown steel buildings ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Q: How long is your delivery time for crown steel buildings ( made of steel frame ) ?

A: Generally it is within 15-30 days after get the deposit and final drawing, definitely according to quantity and your requirements of crown steel buildings ( made of steel frame ).

2) Q: What is the colors of your sandwich panels usually used ?

A: Off-white, ivory white, blue, green and red color.

3) Q: How can I get the quotation of the project ?

A: If you have drawing, we can offer you the quotation as per your dwgs. If you have no design, Our engineer make your idea to real warehouse and will design some drawings for you to confirm. And then offer you a quotation under your material demand and drawing.