|

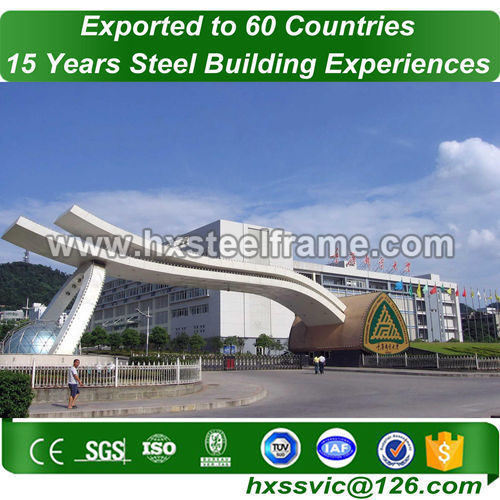

Shandong Huaxing Steel Structure Co., LTD.

|

building prefabrication and steel building kits good price export to China

| Price: | 1000.0 USD |

| Payment Terms: | L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

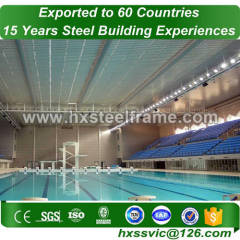

1. Non-destructive test, fully equipped

2. Span:single span or multi span

3. Wall& roof: color steel board or sandwich panel

1. Typical Surface treatment for building prefabrication ( made of steel frame ) :

Surface Treatment |

Hot dip galvanize |

Standard : JIS , DIN , ASTM B695 - 2000 |

Hot dip galvanizing hole cutting good looking on surface |

Galvanizing process : Steel structural components → Degreasing → Rinsing→ Pickling → Rinsing → Fluxing → Galvanizing → Quenching → (Passivation) → Inspecting → Finished Product |

Paint |

1 . Primer paint one coat 20 - 30 um |

2 . Middle paint two coat 40 - 60 um |

3 . Finish paint one coat 20 - 30 um Paint type : 1 . red primer 2 . zinc primer 3 . Alkyd primer |

2. We can supply the service for the follow products:

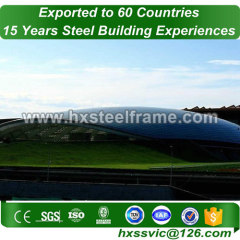

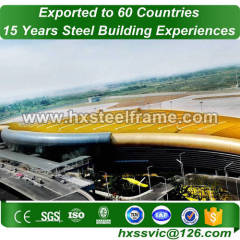

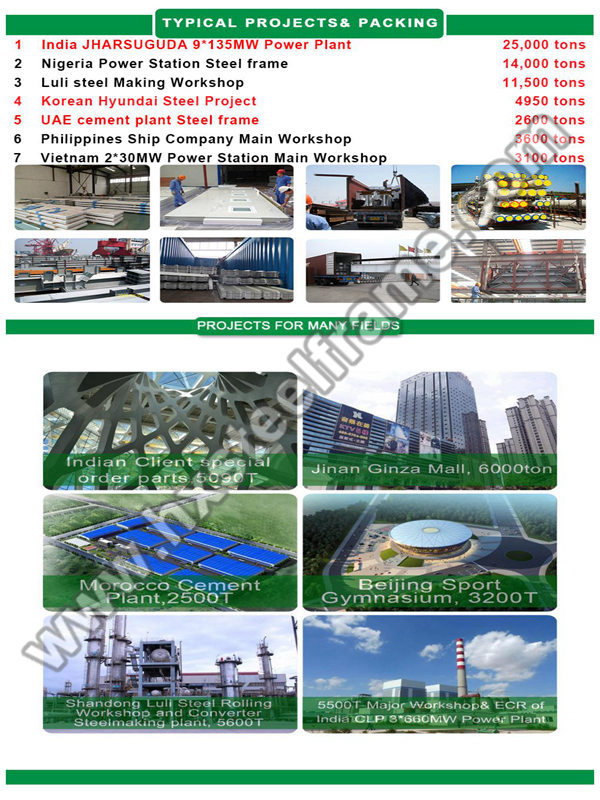

Steel Structure for industrial field, steel structure for civil fields, building prefabrication ( made of steel frame ) , steel buildings, steel workshop, high rise building steel warehouse, steel frame, steel portal frame, etc.

Our best service:

1) You are very welcome to visit our factory before the order, or during the production or after the production before loading.

2) We are very professional in all the kinds of different payment term, FOB, CIF, CFR by sea container or by train.

3) For the steel frame you require, you are very welcome to offer your own design, or you give us your idea, we provide our design, the production, the loading all for you.

3. Project case- Heavy Structure Steel Welding Fabrication for New Zealand, 5900 tons:

Port: Tianjin

Place Of Origin: China

Brand Name: HX

Model Number: OEM And Design

Application: Industrial Usage

Production: H beam, Purlin, Bracing, Bolts

Price: USD 1200 / Ton

Delivery Time: 86 Days

Price Condition: FOB Tianjin Port

Packaging Details: In Seaworthy Packing

Package Weight: 5900tons

4. Our Design Software adopted for building prefabrication ( made of steel frame ) :

We use a series of advanced computation, analysis, design software, and dwgs detailing& mapping software, it including American SAP2000, American STAAD-Pro connection calculation software, Korean Midas gen software of finite element analysis, PKPM, 3D3S, Finland Xsteel, and AUTOCAD, etc.

We use computer workstation to Build 3D model, optimize the design scheme, which increase the product accuracy and material use ratio effectively.

5. Our seaworthy packing system for building prefabrication ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) What will client provide before factory offers good quotation ?

A: When we receive inquiry from client, client need to fills purchasing intention sheet, providing us with information of steel workshop dimensions, draft drawing, wind load etc for prefabricated steel building. We will design the drawings and offer competitive quotation with the above information.

2) What are main materials of building prefabrication ( made of steel frame ) ?

A: Its materials mainly include light steel structure, sandwich panel, roof tile, door, window, covers, screws and other accessories.

3) Could you please design a new and unique building prefabrication ( made of steel frame ) for me ?

A: Absolutely! We are able to provide you with construction scheme

and structural drawings as per your specific demand and favors. Besides, detailed drawings and 3Dmodels are surely included. One-stop service is our outstanding superiority with no doubt.