|

Shandong Huaxing Steel Structure Co., LTD.

|

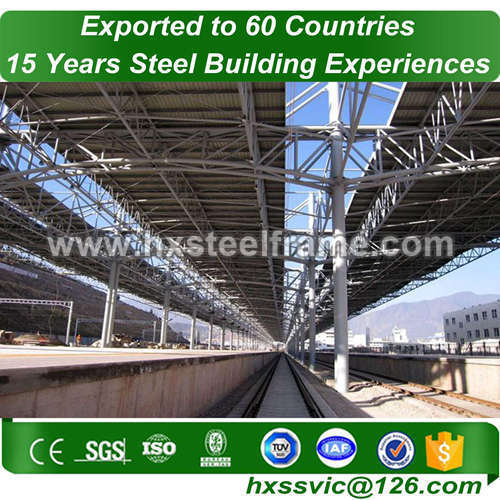

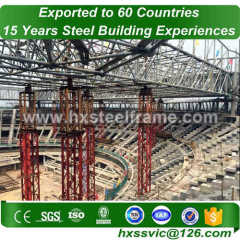

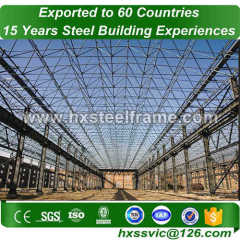

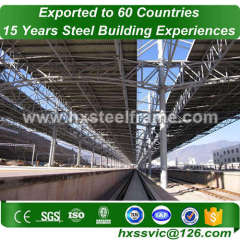

space frame roof construction and steel space frame structures big-Span

| Price: | 1000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. 960 workers, including 50 engineers

2. Building Type: warehouse, workshop, Agri

3. Materials are procured from reputed suppliers

1. Design data of the space frame roof construction ( made of steel frame ) that we need for price evaluation:

We can design the project in 3 days , kindly inform us all the necessary data and information to help us offer the best price and service for you. Such as : | |

Size | Length , width , height , eave height , roof pitch , etc |

Design load | Max wind speed ( KM / H ) , Max snow load ( KG / M2 ) Earthquake |

Roof and Wall material | We can supply single corrugated color steel sheet and EPS sandwich steel panel |

Windows and gates | Size quantity and location |

Surface treatment | Paint or hot dip galvanized |

Any other requirements | |

We believe our best quality steel structure , excellent service and good credibility are worth your trust . If you have needs , please contact us for more information! Looking forward to cooperating with you ! | |

2. Why Our space frame roof construction ( made of steel frame ) is your Right Choice:

1) Stable and deep financial capacity

Any investment is an important decision and should be realized through a financially stable company. Our deep community roots and stout economic strength gives us an exceptional advantage in hiring experienced professionals who will complete your project to your expectations.

2) Competitive Prices

Our production capacity(approximately 200,000 metric tons annually) together with effective and economic engineering and manufacturing methods enable us to offer the most competitive prices in the industry.

3) Fast Quotations

Quotations for simple buildings can be submitted quickly due to vast experience of our staff and the advanced design software we use.

4) Fast Delivery

We are able to design, detail, fabricate and supply simple steel buildings in approximately 4 weeks. Most of our buildings are delivered and erected within 8 weeks(this relies on various factors such as site position, weather etc).

5) Site Supervision

A site supervisor is always present at site to ensure that work is being carried out satisfactorily. Any problems that arise are quickly dealt with to minimize any delays. Safety on site is also made a priority.

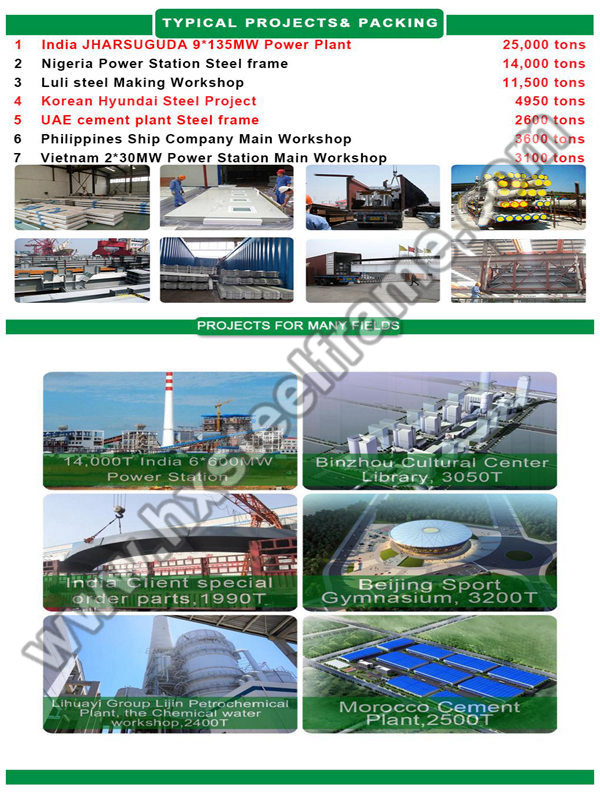

3. Project case- Extended Ship Manufacturing/ Repair Yard& Office Building-Singapore:

Detailed introduction

Location: Singapore, heavy steel structure fabrication work

Tonnage: 2000ton( Including All Main frame and Secondary Structures)

Structure Type: lattice column and truss girder with crane capacity 2x 50T, 1x 32T, 2x 30T, 2x 20T, 2x 15T, 2x 5T.

Execution: October.15, 2012

Difficulty: Material Substitution From British Standard Into Chinese standard and Make the converting and output all the shop-drawings accordingly.

This project, the fabrication standard is as per American standard, all the welders shall have the AWS welder certificate, the 3rd party QC will stay in our factory track the whole fabrication process. Finally after 50 days efforts, our products pass the inspection by client 100% at once. Client feel happy to work with us. Now we are the VIP supplier in client' s list.

4. Service we provided for the space frame roof construction ( made of steel frame ) :

1) Pre-Sales Service:

Inquiry and consulting support.

View our Factory.

2) After-Sales Service:

Training how to install the steel structure, training

Engineers available to do some instruction of steel structure overseas.

5. Our seaworthy packing system for space frame roof construction ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Why should I build steel building using steel structure ?

Steel has the higher strength.

80% recyclable, Steel is the most recycled material in the world.

No warping, no cracking, no chemical treatments.

Stronger connection.

Lower transport costs due to lightweight frames.

Steel frames will not burn, fire proof.

Lightning will not affect a steel framed house since steel creates a positive earth. Lightning energy is conducted straight to the ground.

Each steel structure is a independent engineered.

2) How difficult is it to install space frame roof construction ( made of steel frame ) ?

Too easy! Some customers who purchase prefabricated steel building choose to install their own warehouse using local erection team.