|

Shandong Huaxing Steel Structure Co., LTD.

|

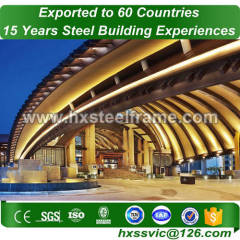

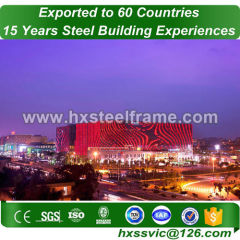

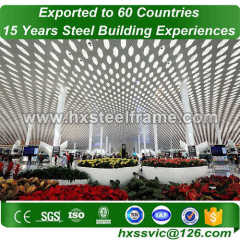

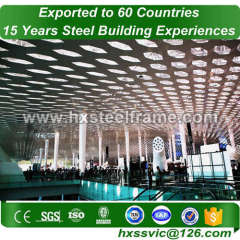

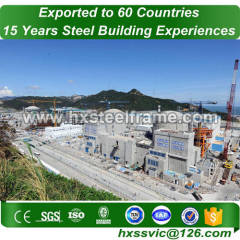

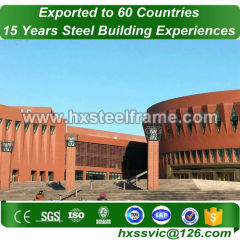

light steel framing systems and prefab metal buildings big-Span at China area

| Price: | 1000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Wall& roof panels: be packed by plastic film

2. Surface processing: painted or galvanized

3. Certification ISO9001: 2008, by BV France

1. light steel framing systems ( made of steel frame ) main components :

SIZE(m) | LENGTH * WIDTH * EAVE HEIGHT |

TYPE | SINGLE SPAN , DOUBLE SPAN , MULTI - SPAN |

ONE FLOOR , TWO FLOORS , THREE FLOORS | |

BUILDING FOUNDATION | STEEL FOUNDATION WITH ANCHOR BOLTS |

COLUMN & BEAM | MATERIA L :Q235B & Q345B |

BRACING | X or V TYPE BRACING MADE BY ANGEL STEEL , ROUND Bar etc |

Wall & Roof C or Z PURLINE | SIZE :C120 ~ C320mm ; Z100 ~ Z300mm |

WALL & ROOF PANEL | SINGLE CORRUGATED STEEL SHEET |

SANDWICH PANEL INSULATION WITH EPS , PU , ROCK WOOL etc | |

WINDOW & DOOR | PVC or ALUMINIUM ALLOY WINDOW |

ELECTRIC ROOL - UP DOOR | |

SLIDING DOOR BY SANDWICH PANEL OR SINGLE CORRUGATED STEEL SHEET | |

SURFACE TREATMENT | HOT GALVANIZED COATING COLD GALVANIZING |

Spray - Painting , Any color , or according to your request | |

ACCESSIORES | SEMI - TRANSPARENT SKYLIGHT BELTS |

VENTILATORS ; DOWN PIPE ; GUTTER | |

STANDARD BOLTS |

2. Why Our light steel framing systems ( made of steel frame ) is your Right Choice:

1) Stable and deep financial capacity

Any investment is an important decision and should be realized through a financially stable company. Our deep community roots and stout economic strength gives us an exceptional advantage in hiring experienced professionals who will complete your project to your expectations.

2) Competitive Prices

Our production capacity(approximately 200,000 metric tons annually) together with effective and economic engineering and manufacturing methods enable us to offer the most competitive prices in the industry.

3) Fast Quotations

Quotations for simple buildings can be submitted quickly due to vast experience of our staff and the advanced design software we use.

4) Fast Delivery

We are able to design, detail, fabricate and supply simple steel buildings in approximately 4 weeks. Most of our buildings are delivered and erected within 8 weeks(this relies on various factors such as site position, weather etc).

5) Site Supervision

A site supervisor is always present at site to ensure that work is being carried out satisfactorily. Any problems that arise are quickly dealt with to minimize any delays. Safety on site is also made a priority.

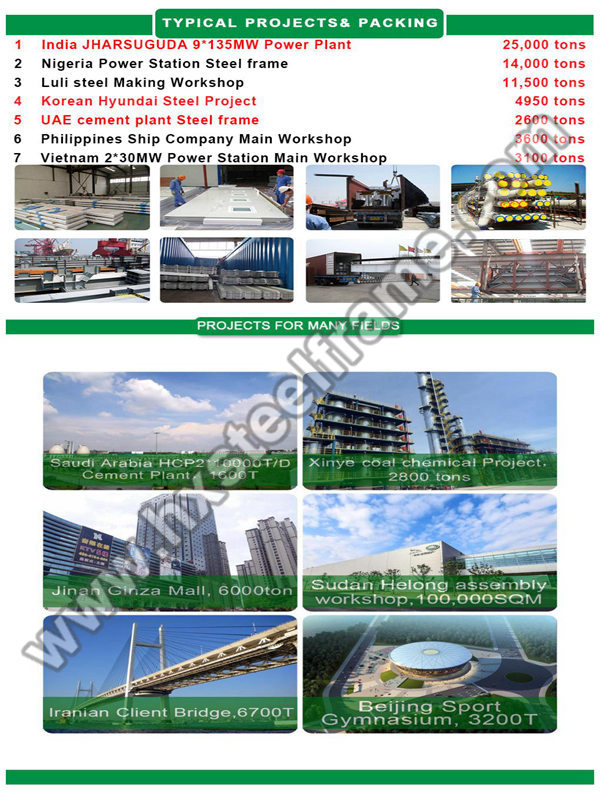

3. Project case- Angola steel structure project, 18800m2:

In 2003, Our company took over the workshop steel structure project of an Angola company, the steel structure building has been completed by now. The whole steel structure building area is 18800m2. This steel structure is particularly special, it has a certain technical difficulties. In order to carry on the project installing smoothly, Our company sent an outstanding engineer to direct the installation of the steel structure building. With 3 months hard work, we completed the project perfect finally. The customer was very satisfied with our work and gave the new steel structure workshop project drawing to us, we were excited about this. This indicates that the customer is well accepted with our steel structure production and they trust Our company. Therefore, we will work harder to make more satisfying steel structure for customers.

4. Design & Engineering strength on light steel framing systems ( made of steel frame ) :

The engineering work in structural steel design includes in-depth analysis and design of the complete structure, in addition to the preparation of construction drawings and shop details.

1) We are an ISO 9001 certified company by UL Inc. USA, for design and manufacture of Pre-Engineered Steel Building Systems and Structures.

2) Our structural design team of 100 dedicated professionals and senior structural designers, is well equipped to work in accordance with all Chinese and international codes.

3) State-of-art technology is used for detailed design which is at par with international building design standards. All our steel buildings are designed using the most advanced metal building soft wares like Staad Pro, MBS, Tekla and others.

5. Our seaworthy packing system for light steel framing systems ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) How to buy your ideal light steel framing systems ( made of steel frame ) ?

A: TT and L/C are acceptable and TT will be more appreciated. 30% deposit before producing, balance before loading by TT.

2) What is the delivery time of light steel framing systems ( made of steel frame ) ?

A: It all depends on the order quantities. Usually, delivery time will be within 1 to 2 months.

3) How to install after the goods arriving destination ?

A: We will provide detailed erection dwgs to you. If it is necessary, we will send technicians to help you. However, the visa fee, air tickets, accommodation, wages will be paid by buyers.

4) Q: Does your steel building can only be used in residential building ?

A: Absolutely not. It can be used in all kinds of buildings, such as hotel, commercial office, school, entertainment club, light industrial workshop, etc.