|

Shandong Huaxing Steel Structure Co., LTD.

|

structural steel sections formed steel buidings lightweight hot sale in Greece

| Price: | 1000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Sandwich panel into container piece by piece

2. Certification ISO14001: 2004, by BV France

3. Installation: erection Drawing or Guide on Site

1. Data of the Steel building ( made of structural steel sections ) :

Specification | |

Material : | Grade Q235 , equivalent to ASTM A36 Grade Q345 , equivalent to ASTM A572 |

Section : | Any product shape according to customer's requirements |

Certification : | ISO quality system , Chinese GB50221 - 2001 |

Sand Blast : | SA 2.5 Sand blasting |

Welding Technology : | Single level butt welding , fillet welding by electric arc welding , and Gas shielded welding |

Surface treatment : | Hot dip galvanized , Epoxy zinc rich primer Standard : ISO1461 ( 1999 ) , JIS H 8641 - 1999 , ASTM A 123 / A 123M-02 |

Welding Testing | Ultrasonic Testing , X-ray Testing |

Manufacturing Technology | Drilling , Cutting , Assembling , Welding , Rectification , Testing etc |

2. About our company:

1) We have a group of professional engineers, most of whom has more than 10 years' experiences in architecture field.

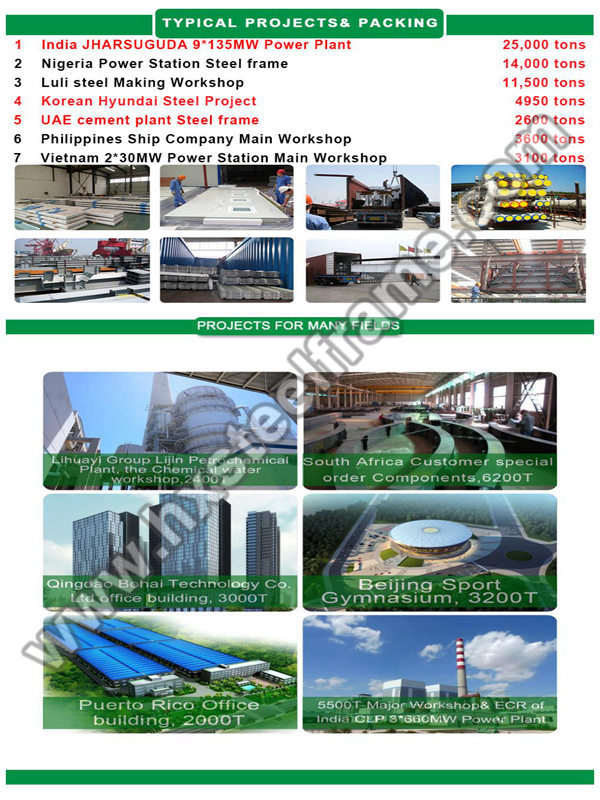

2) Established for more than ten years, our company has got a various of experiences in all kinds of steel structure& steel building design, manufacture, installation and so on. The work staffs have excellent skills. Some of them had helped customers to install the warehouse around the world.

3) We have the capacity of annually 200,000 tons steel structure. We also have possessed more than 300 sets of large precise and advanced processing equipment, including large gantry planning machines, automatic submerged arc welding machines, assembling machines, shot blasting machines and so on.

3. Project case- Angola steel structure project, 18800m2:

In 2003, Our company took over the workshop steel structure project of an Angola company, the steel structure building has been completed by now. The whole steel structure building area is 18800m2. This steel structure is particularly special, it has a certain technical difficulties. In order to carry on the project installing smoothly, Our company sent an outstanding engineer to direct the installation of the steel structure building. With 3 months hard work, we completed the project perfect finally. The customer was very satisfied with our work and gave the new steel structure workshop project drawing to us, we were excited about this. This indicates that the customer is well accepted with our steel structure production and they trust Our company. Therefore, we will work harder to make more satisfying steel structure for customers.

4. Payment Terms & Delivery for Steel building ( made of structural steel sections ) :

Payment: L/ C or by T/ T( 30% prepaid as deposit, balance 70% before shipment)

Delivery time: 15 to 40 days, usually as customers' order

Shipment: 20' GP, 40' GP, 40' HQ, or in bulk

5. Packaging & Shipping for Steel building ( made of structural steel sections ) :

1) Using container:

container of 20 feet, and container of 40 feet

2) By sea for batch goods, for container or bulk-cargo ship, port receiving.

3) Customers specifying freight forwarder or negotiable shipping methods

4) All of the steel column& beams ends and plates will be packed by the blanket to protect them from the crash in the container during the shipment.

5) To make the loading and unloading more efficiently and saving the delivery cost, 40' OT is preferred to loading the steel frames.

6) All the wall and roof panels will be filmed by two sides and fixed stably in the 40HQ container.

7) All the windows and doors will be protected by the bubble rapping papers and fixed stably in the container.

6. FAQ:

1) Is there a clear service life of your Steel building ( made of structural steel sections ) ? If have, how long ?

Under conventional climate and environment, steel structure whole building 30 years, main structure 50 years, protecting system 30 years.

2) What designs do you have in different climates? How can the Steel building ( made of structural steel sections ) adopt to different climates?

Strong wind region: improve the wind-resisting ability of the internal structure.

Cold region: increase the thickness of the wall, or use good insulation material, improve anti-pressure ability of the structure.

High corrosion region: use corrosion resistant material, or paint anti-corrosive coating.