|

Shandong Huaxing Steel Structure Co., LTD.

|

structural steel welding light steel structure AWS welding

| Price: | 1000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Wall& roof panels: be packed by plastic film

2. We are an ISO 9001: 2000 certified company

3. Software: Auto CAD, PKPM, MTS, 3D3S

1. Specification of Steel building ( made of structural steel welding ) :

Steel Structure | Function | Material | Surface Finish | Design | ||

main Frame | Support / wind resistance / bearing weight | Q345 B for beam , column

| painted / galvanized | portal frame or space frame | ||

secondary frame | Support , connect and strengthen , sag rod , bracing , tie bar , etc | Q235B | Drilling , sand blasting , paint, ready to connect | |||

Purlin | supporting for cladding | Q235B for C or Z purlin | galvanized | |||

Roof & wall panel | Insulation / water-proof / fire resistance / wind - resistance | sandwich panel ( EPS / rock wool / PU / glass wool ) / single skin steel sheet | Galvanized / galvalum / color coated | Corrugated / flat | ||

thickness of sandwich panel ( 50mm / 75mm / 100mm / 150mm ) steel sheet : 0.35mm - 0.6mm | ||||||

window | Daylight / air circulation / decoration | pvc steel / aluminum alloy / glass | customized | Sliding / roll-up | ||

Door | Security / insulation / water - proof | steel sheet / sandwich | Prepainted / galvanized | Sliding / rolling up | ||

Accessory | self-locked nail , steel bracket , high strength bolts , self-drilling screw , rivet , inter and outer cullis , rain spout , trimming sheet , glass cemen | |||||

Life span | > 50 years | |||||

Feature | Multi - functional | perfect for workshop / warehouse / power plant / cafe / exhibition hall / GYM / Concert hall / car - parking / 4s shops / logistics etc | ||||

Reusable | 100% light steel structure material can be reused | |||||

Wide span | the max span is 36m without middle column | |||||

fast construction | prefabricated unit component | |||||

stable and durable | excellent anti - quake effects | |||||

Cost - effective | half of the cost of common construction system | |||||

enlarge the space | make the most use of the property of steel structure | |||||

perfect combination between mechanical property and art | Different plan based on different requirements | |||||

considerate design | CAD Drawing and other software | |||||

2. Why Our Steel building ( made of structural steel welding ) is your Right Choice:

1) Stable and deep financial capacity

Any investment is an important decision and should be realized through a financially stable company. Our deep community roots and stout economic strength gives us an exceptional advantage in hiring experienced professionals who will complete your project to your expectations.

2) Competitive Prices

Our production capacity(approximately 200,000 metric tons annually) together with effective and economic engineering and manufacturing methods enable us to offer the most competitive prices in the industry.

3) Fast Quotations

Quotations for simple buildings can be submitted quickly due to vast experience of our staff and the advanced design software we use.

4) Fast Delivery

We are able to design, detail, fabricate and supply simple steel buildings in approximately 4 weeks. Most of our buildings are delivered and erected within 8 weeks(this relies on various factors such as site position, weather etc).

5) Site Supervision

A site supervisor is always present at site to ensure that work is being carried out satisfactorily. Any problems that arise are quickly dealt with to minimize any delays. Safety on site is also made a priority.

3. Project case- Xinwenhua Center Auditorium:

Project Overview:

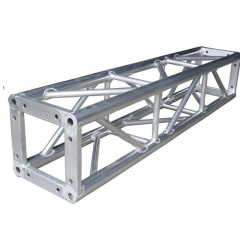

Fabricate and erect approximately 2500 tonnes of structural steel work. The majority being roof steel work over the auditorium which was supported by four 29m long trusses spanning between the reinforced concrete walls.

The trusses were pre-fabricated in sections and as we were faced with a very tight city centre site it was essential to work very closely with other sub-contractors to plan the on site assembly of the trusses prior to installation.

4. We are extremely powerful in supplying Complex Steel Structures:

We are good at flexible and versatile production for the fabrication of complex and heavy steel pieces and structures, thanks to:

1) Advanced engineering

2) Proven fabrication processes adapted for carrying out these types of unique products

3) Know-how and long-standing experience in fabrication of complex steel built-ups

4) Lifting capacity of 200 tons for handling fabrication work of heavy steel built-ups

5) Large working areas to carry out assembly work of oversized steel built-ups

6) Important fabrication capacity for large scale projects

The weight and size of these types of products or the combination of these factors can be challenging, especially in terms of handling activities in the plant and transport. As such, certain of the steel built-up components weighing over 60 tons have to be shipped in sections to the construction sites where they will be installed.

5. Packaging& Shipping for Steel building ( made of structural steel welding ) :

1) All the structure components, panels, bolts and sorts of accessories will be well packed with standard package suitable for ocean transport and loaded into 40' HQ.

2) All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers, who will prevent the goods to be damaged.

3) Good relationship with many vessel companies to make sure the transportation smooth.

6. FAQ:

1) Why should I build steel building using steel structure ?

Steel has the higher strength.

80% recyclable, Steel is the most recycled material in the world.

No warping, no cracking, no chemical treatments.

Stronger connection.

Lower transport costs due to lightweight frames.

Steel frames will not burn, fire proof.

Lightning will not affect a steel framed house since steel creates a positive earth. Lightning energy is conducted straight to the ground.

Each steel structure is a independent engineered.

2) How difficult is it to install Steel building ( made of structural steel welding ) ?

Too easy! Some customers who purchase prefabricated steel building choose to install their own warehouse using local erection team.