|

Shandong Huaxing Steel Structure Co., LTD.

|

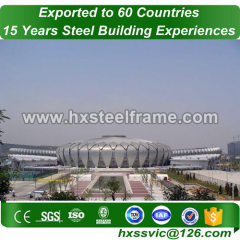

heavy Steel frame prefab buildings nz excellent TEKLA design

| Price: | 1000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Non-destructive test, fully equipped

2. NDT on welding joints is carried out

3. Scope: warehouse, workshop, poultry shed etc

1. Steel building ( made of heavy Steel frame ) main components description :

1 ) Mainly made by H - section and box girder .

Wide flanges make H - beam have a higher lateral stiffness fit for compression member .

Flanges of H - section with same thickness parallel with one another have strong resistance to bending , easy to composite and joint with other component for your prefab steel structure workshop .

2 ) Support System

Support system of prefab steel structure workshop mainly consist of purlin , cross bracing and angle brace made by Z - section , C - section or angle , allot the payload of column and pillar , transfer the loading to whole frame .

Support system makes the frame structure stand as a unity ; improve the solidity and stabilization of frame itself .

3 ) Roof and wall panel system

Roof and wall panel system mainly made of color steel or color steel sandwich panel .

Roof and wall panel system connected by self-tapping screw , easy and fast to assemble .

Good mechanical property as well as bearing capacity of prefab steel structure workshop .

Multiple color and surface finishing available meet your customization requirement and preference for prefab steel structure workshop .

2. What we could do for you:

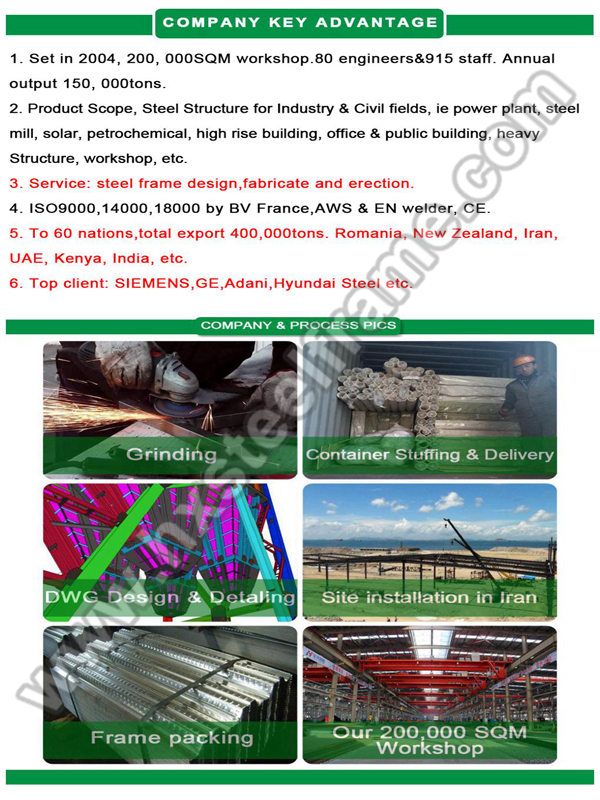

We specializing in steel structure design, manufacturing, installation and sale and featuring advanced technology. Taking the advantages of rich experience in management and cutting-edge technology in steel structure industries, based on production management system, we have established an effective interior production and operation system.

We can make almost all types of land based steel structure products, including steel workshop, warehouse, Steel building ( made of heavy Steel frame ) , high rise steel building, etc. It is making efforts to explore the markets at home and abroad with a brand name of quality products to boost the development of the steel structure market and products in China.

3. Project case- Uganda Steel Coil Processing Plant:

Detailed introduction

Project Description: 30x 120M

Project Type: Gable frame PEB structure with office mezzanine building, Stairs, Platform, etc

Time: Oct. 25, 2012

Location: Uganda

Description:

Site anchor bolt installation all ready finished as planed and all engineering are made as per existing plan to save the client' s investment cost of foundation preparation. We supply the steel structure and panel system within 20 days, which make client very satisfied and we found continuous cooperation with this client after the 1st order.

4. Certificates & Quality Management for the Steel building ( made of heavy Steel frame ) :

We have ISO9000, 14000, 18000 by BV France, AWS& EN welder, CE etc to ensure our whole production progress controllable.

We also have systematic Quality Process and Progress Control documentation: Our fabrication process have been controlled by series of documentation and quality testing which are monitored and certificated by BV, SGS, SKM, JACOBES etc world-famous third party inspection organization.

5. Packing & Delivery for Steel building ( made of heavy Steel frame ) :

For Main Components: Put steel structure components on a steel pallet and tie up the frame part together by packing strap with wood beam and cardboard, then load into container by crane or forklift

For cladding: Plastic film wrap the roof and wall corrugated single steel plate.

but for sandwich panel will load into container piece by piece

This package is to protect the goods from damage, during the transportation.

Delivery:

Load into 40/ 20GP, 40HQ, 40OT or Bulk carrier.

Delivery Time: 15 to 30 days after the receiving deposit or according to client' s requirements.

6. FAQ:

1) Can I have a visit to your factory before the order ?

A: Why not ? welcome to visit our factory. You can fly to Jinan Airport. We will pick you up in the airport. Hotel booking service is available.

2) Do you supply installation service for Steel building ( made of heavy Steel frame ) ?

A: Yes, we do. But you will pay for our professional fee if we install in your local place. Then we will send engineers to supervise it.

3) How long can the Steel building ( made of heavy Steel frame ) be used ?

A: The use life of the main structure is the designed used life, that is 50-100 years( standard request of GB) .