|

Shandong Huaxing Steel Structure Co., LTD.

|

light metal frame lightweight steel frame BV verified

| Price: | 1000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. For big single steel parts, no need to pack

2. Steel grade is Q235B or Q345B

3. Wide span: single or multiple span, max span 36m

1. Technical specs for the Steel building ( made of light metal frame ) :

Item name | Material characteristics | Material Grade | Surface Treatment |

Anchor bolt | Steel rod M24 , M27 | Q235B | |

Steel Column | H shape , Box , steel pipe , Hot rolled sheet | Q235B , Q345B | Paint or Hot dip galvanized |

H shape , steel Truss , Hot rolled sheet | Q235B , Q345B | Paint or Hot dip galvanized | |

Steel Bracing | Steel rod , Steel pipe , Angle steel | Q235B , Q345B | Paint |

Steel Purlin | C or Z shape , steel purlin Thickness :1.8mm ~ 3.0mm | Q235B , Q345B | Hot dip galvanized |

External wall panel , Roof panel | Sandwich panel with EPS , Rock wool , Pu , Glass wool | Steel T = 0.426 ~ 0.8mm , insulation T=50 ~ 150mm | Alu-zinc galvanized then painted |

Door | Sliding or rolling door | Steel or Aluminum sheet , T = 1.0 ~ 1.5mm | Paint or Hot dip galvanized |

Window | alloy-Glass , Aluminium alloy - shutter | T = 1.0 ~ 2.0mm | Alloy |

Day-lighting panel | FRP , T = 1.5mm or T = 1.8mm | Coefficient of thermal expansion : 2.2 x 10 - 5 / cm | Light transmittance 85% |

Ventilator | Turbine ventilator, ventilator along a slope | Steel , stainless steel , PC | Paint , 304 |

Gutter | Galvanized Steel plate , stainless steel plate | T = 2.0mm | Paint , 304 |

Downpipe | PVC pipe , T = 0.5mm | Φ110 , 160 , 200 | |

Bolt | Ordinary , high strength | 10.9S , 4.8s | Bluing for high strength bolts |

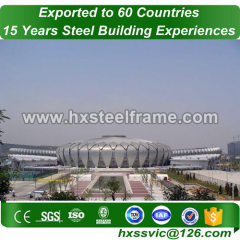

2. Our company advantage:

1) Enough capacity

Our factory is occupies an area of 200000 m2, We have 1020 workers. 15, 000tons steel structure per month, So we have enough capacity for your demand on Steel building ( made of light metal frame ) .

2) Advanced technology

There are 300 sets advanced technology equipment. The CNC cutting machines which are imported from USA to make sure the precise size be cut.

3) customized design

We have 62 senior design engineers, 25 shop dwg detailing engineers. our technology department can make a optimal design just for you review according your requirements and local weather condition.

3. Some of OUR WORKSHOP/ WAREHOUSE PROJECTS:

1) AREVA Transformer Factory Project:

Covering an area totaled 33, 842 sq.m, the program consumed steel in 4299 tons, the column height is 31-33 m, and the inside is installed with the bunk bed traveling crane with the maximum hoisting capacity in 400 tons.

2) NEW ZEALAND Barns / Grain Warehouses:

light gauge steel structure with cold bended profiles.

3) BOLIVIA Cement Plant:

Steel consumption: 3, 655 tons in the first phase, 7200 tons in the second phase.

4) LDK Polysilicon Public Project:

Was generally contracted by FLR CO., LTD, the total steel consumption volume for Phase I project reached over 3000 tons and this program was in a high-rise steel structure of 4-7 floors.

4. Our service for the product of Steel building ( made of light metal frame ) :

1) We provide free design and technical support work: according to the plan, size requirements, use function and load conditions provided by the owner; we will provide free architecture scheme drawings, component detail drawings, installation instruction drawing, installation instructions files.

2) Coordination in product transportation

We' ll track products' transportation in whole course, and actively help customers solve all problems during product transportation.

3) Installation guidance

If our customer needs, we will assign engineers for on-site installation guidance work.

5. Packing & Delivery for Steel building ( made of light metal frame ) :

For Main Components: Put steel structure components on a steel pallet and tie up the frame part together by packing strap with wood beam and cardboard, then load into container by crane or forklift

For cladding: Plastic film wrap the roof and wall corrugated single steel plate.

but for sandwich panel will load into container piece by piece

This package is to protect the goods from damage, during the transportation.

Delivery:

Load into 40/ 20GP, 40HQ, 40OT or Bulk carrier.

Delivery Time: 15 to 30 days after the receiving deposit or according to client' s requirements.

6. FAQ:

1) How to control the quality of your Steel building ( made of light metal frame ) ?

a. quality of the design: think about possible problems in advance and provide a high quality design solution.

b. quality of the raw material: choose the qualified raw material from the top steel mill in China.

c. quality of the production: precise manufacturing technique, experienced workers, strict quality inspection.

2) How to deal with quality problems of your Steel building ( made of light metal frame ) ?

Warranty is 2 years. Within the warranty period, we will responsible for all quality problems caused by production.