|

Shandong Huaxing Steel Structure Co., LTD.

|

commercial steel buildings and commercial steel buildings as per AWS1.1

| Price: | 1000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Delivery time: 15 to 40 days, or as client order

2. Fast installing, time saving and labor saving

3. High quality welding process are used

1. How to build a commercial steel buildings ( made of steel frame ) , please check the following table :

Design Data ( important ) | live load on roof ( KN / M2 ) wind speed ( KM / H ) snow load ( KG / M2 ) if have |

Size ( important ) | width length height roof slope |

Type | single slope or double slope muti slope or single span single floor or two floors |

Inter column | 5m , or 6m …. |

Windows & Door | 1 . quantity 2 . size 3 . Location 4 . PVC or aluminum |

Column &Beam | straight cross-section OR Variable cross-section |

Roof & Wall Panel | 1 . Colorful corrugated steel sheet 0.326~0.8mm thick , YX25-210-840 ( 840mm wide ) 3 . sheet+glass fiber(thick 50mm~200mm) |

Purlin | 1 . C purlin 2 . Z purlin |

Accessories | Do you need the skylight belts , Ventilators,down pipe , out gutter etc ? |

Surface Treatment | Shot blasting with anti rust paint or hot dip galvanize |

2. About the product:

1) Product scope:

commercial steel buildings ( made of steel frame ), steel structure warehouse / workshop / hangar / garage / poultry house, high rise steel building, industrial steel frame, sandwich panel, welded H steel, C/Z channel, corrugated steel sheet, etc.

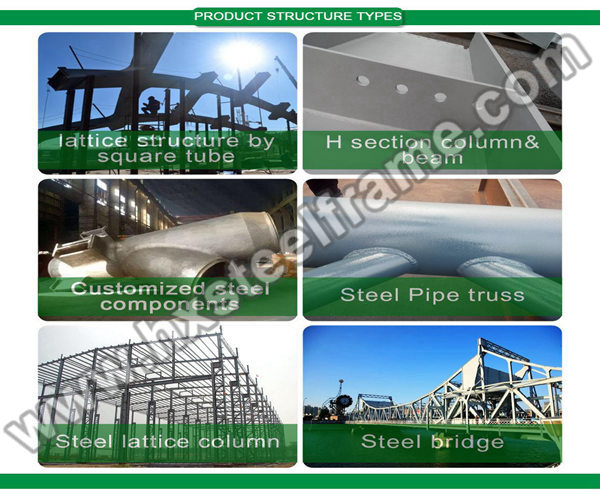

2) Products structure type& Service:

Design & fabrication & Engineering Service, Steel Building, Space Frames, lattice steel structure, Tubular Steel Structures, basic building elements( built-up welded H-section, hot-rolled H-section, channel, steel column, steel beam), standard frames, secondary framing, roof & wall materials.

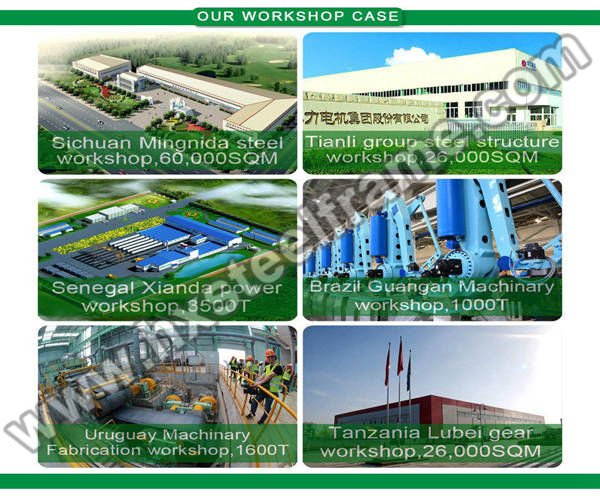

3. Project case- South Africa Light Pre-engineered Building, 7000SQM, 2011:

South Africa workshop project

usage: steel pipe production workshop

length 252M X width 27.5M X height 11M, with a crane of 30 ton, the crane sling height is 7M. The workshop adopt Frame bent structure, lattice form column. Roof and wall surface is single steel sheet, no heat insulation, the bottom of wall has brick wall that 800 mm height and aluminum windows that 1.8m height, skylight sheet on roof for lighting.

Client issue the order to us within 1 week after visit our factory, our hardware and ISO management system leave deep impression to them. Now, we have finished more than 6 orders for this client.

4. Payment Terms & Delivery for commercial steel buildings ( made of steel frame ) :

Payment: L/ C or by T/ T( 30% prepaid as deposit, balance 70% before shipment)

Delivery time: 15 to 40 days, usually as customers' order

Shipment: 20' GP, 40' GP, 40' HQ, or in bulk

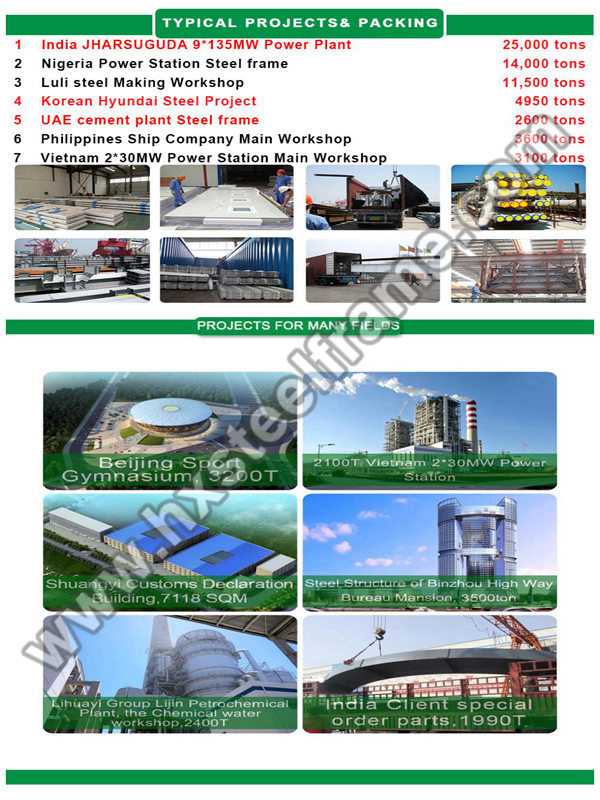

5. Our seaworthy packing system for commercial steel buildings ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Is there a clear service life of your commercial steel buildings ( made of steel frame ) ? If have, how long ?

Under conventional climate and environment, steel structure whole building 30 years, main structure 50 years, protecting system 30 years.

2) What designs do you have in different climates? How can the commercial steel buildings ( made of steel frame ) adopt to different climates?

Strong wind region: improve the wind-resisting ability of the internal structure.

Cold region: increase the thickness of the wall, or use good insulation material, improve anti-pressure ability of the structure.

High corrosion region: use corrosion resistant material, or paint anti-corrosive coating.