|

Shandong Huaxing Steel Structure Co., LTD.

|

commercial metal framing building made of light steel structure recyclable

| Price: | 1000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. More than 80 senior & middle rank engineers

2. Building Type: warehouse, workshop, Agri

3. Certification ISO14001: 2004, by BV France

1. Technical specs for the commercial metal framing building ( made of steel frame ) :

Item name | Material characteristics | Material Grade | Surface Treatment |

Anchor bolt | Steel rod M24 , M27 | Q235B | |

Steel Column | H shape , Box , steel pipe , Hot rolled sheet | Q235B , Q345B | Paint or Hot dip galvanized |

Steel Beam | H shape , steel Truss , Hot rolled sheet | Q235B , Q345B | Paint or Hot dip galvanized |

Steel Bracing | Steel rod , Steel pipe , Angle steel | Q235B , Q345B | Paint |

Steel Purlin | C or Z shape , steel purlin Thickness :1.8mm ~ 3.0mm | Q235B , Q345B | Hot dip galvanized |

External wall panel , Roof panel | Sandwich panel with EPS , Rock wool , Pu , Glass wool | Steel T = 0.426 ~ 0.8mm , insulation T=50 ~ 150mm | Alu-zinc galvanized then painted |

Door | Sliding or rolling door | Steel or Aluminum sheet , T = 1.0 ~ 1.5mm | Paint or Hot dip galvanized |

Window | alloy-Glass , Aluminium alloy - shutter | T = 1.0 ~ 2.0mm | Alloy |

Day-lighting panel | FRP , T = 1.5mm or T = 1.8mm | Coefficient of thermal expansion : 2.2 x 10 - 5 / cm | Light transmittance 85% |

Ventilator | Turbine ventilator, ventilator along a slope | Steel , stainless steel , PC | Paint , 304 |

Gutter | Galvanized Steel plate , stainless steel plate | T = 2.0mm | Paint , 304 |

Downpipe | PVC pipe , T = 0.5mm | Φ110 , 160 , 200 | |

Bolt | Ordinary , high strength | 10.9S , 4.8s | Bluing for high strength bolts |

2. About us:

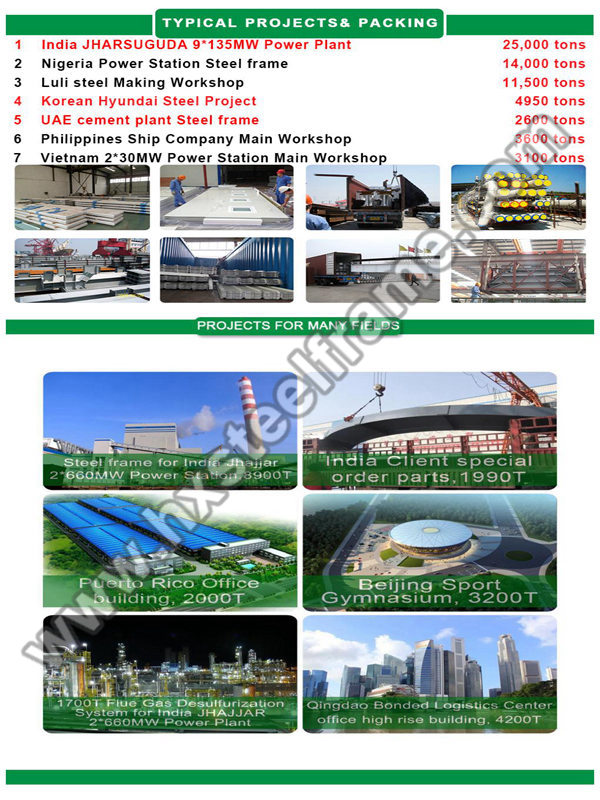

We are a modern steel structure building enterprise specialized in engineering design, manufacture, installation and service of steel structures; and its manufacturing base is situated in Shandong, China. Due to customers' trust and constant innovation of our team, the enterprise is now with a total area of 360, 000 m2 as regards our plants.

We have passed ISO9001: 2000 International Quality System Certification and has a level-one qualification of steel structure project specialized contracting. The enterprise has been verified by BV and SGS which are two global largest verification organizations.

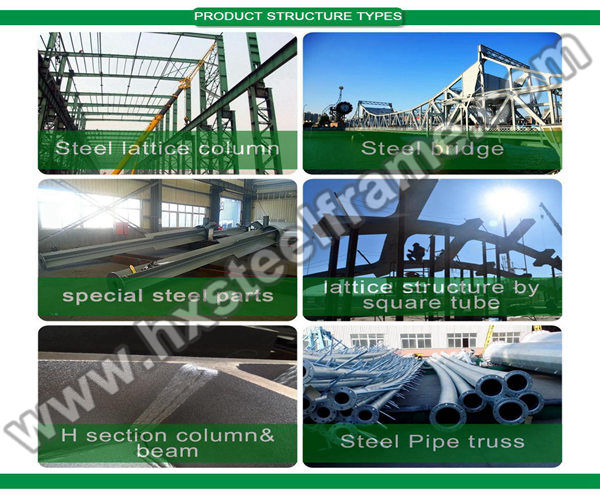

The business scope of us are various steel building, such as steel structure workshop, warehouse, multi-storey building, prefab steel house, container steel house, high-rise frame building and frame structure for large equipment, etc. We also supply various steel structure materials, such as H-type steel, color steel sheet, C-type purlin, Z-type purlin, floor deck as well as steel beam and steel column.

3. Project case- South Africa Light Pre-engineered Building, 7000SQM, 2011:

South Africa workshop project

usage: steel pipe production workshop

length 252M X width 27.5M X height 11M, with a crane of 30 ton, the crane sling height is 7M. The workshop adopt Frame bent structure, lattice form column. Roof and wall surface is single steel sheet, no heat insulation, the bottom of wall has brick wall that 800 mm height and aluminum windows that 1.8m height, skylight sheet on roof for lighting.

Client issue the order to us within 1 week after visit our factory, our hardware and ISO management system leave deep impression to them. Now, we have finished more than 6 orders for this client.

4. How we ensure the high quality of commercial metal framing building ( made of steel frame ) :

After years of exploration, practice and improvement, our company has built an experienced technical team in steel structure. Every project is supposed to go through the following procedures:

1) Owing plasma cutting, flame cutting, available to provide multiple cutting service.

2) Well-experienced engineer team and production team for steel structure fabrication, welder working with CWI certificate, according to WPS( welding procedure specification) and PQR( procedure qualification record) .

3) Professional non-destructive testing, fully equipped.

4) Professional surface treatment: sandblasting, paint spraying, powder coating as per American standard.

5) More than 10 years steel structure fabrication experience

6) Full set of manufacturing process plan to ensure delivery on time.

5. Our seaworthy packing system for commercial metal framing building ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Q: How could I control the cost of building a commercial metal framing building ( made of steel frame ) ?

A: Firstly, the designing scheme should be mutually discussed and then accepted. Then, the kinds of building materials should be confirmed since different types and qualities make various prices. After that, we will send you a detailed quotation.

2) Q: How Long does it take to build a commercial metal framing building ( made of steel frame ) ?

A: It depends on the size of the warehouse. Generally, the construction period of is 1 month of a 2000-square-meter workshop by a construction team of 8-10 people. It only costs 2-3 weeks to build the steel structure frame.

3) Q: Is it difficult to build a commercial metal framing building ( made of steel frame ) ?

A: totally not, you can let your local teams build it according to the construction drawings and erection guiding video provided by us.