|

Shandong Huaxing Steel Structure Co., LTD.

|

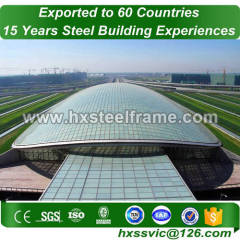

metal building installation made of steal frame rust proof sale to Malta

| Price: | 1000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Shipping depended on order quantity

2. Engineers' guidance on-site is available

3. EPS sandwich panel( for wall, roof, floor)

1. Products description for the metal building installation ( made of steel frame ) :

Main Steel | |

Steel Beam Column | Q235B , Q345B |

Secondary Steel | |

Tie Bar | Q235B |

Purlin | C and Z purlin |

Bracing | Q235B |

Accessories | |

Surface | Painted or Hot Dip Galvanized |

Door | Rolling Up Door or Sliding Door |

Window | PVC or Aluminum Alloy |

Roof and Wall Panels | Corrugated Steel Sheet , EPS Sandwich Panel , Rock Wool Sandwich Panel , PU Sandwich Panel |

Others | |

Service | Design , Fabrication and Installation |

We can offer quotations according to customers' drawings and requirements , free design drawings and detailed installation drawings . | |

Design software : Auto CAD , PKPM , MTS , 3D3S , TArch , Tekla Structures ( X steel ) V12.0 , etc | |

Packing | main steel frame with 40 OT roof and panel load in 40 HQ Or According To Customer Requirement |

2. Why choose us as your steel structure supplier:

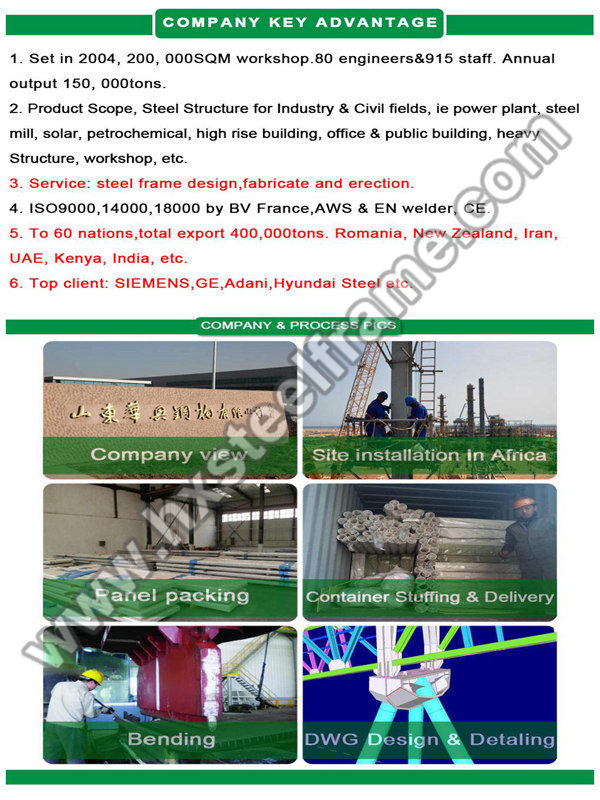

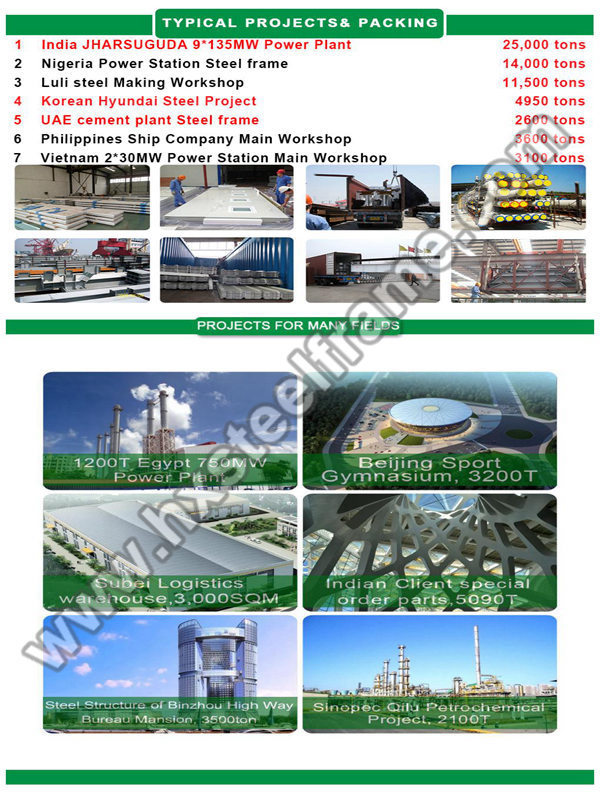

Founded in Shandong province, we are a professional manufacturer of steel structure building, workshop, warehouse, high rise building, industrial steel structure, civil steel structure, sandwich panel and profiled steel with ISO9001, SGS and CE certification.

We once made 30, 000 SQM prefabricated building in 16 days for a major buyer in Saudi Arabia. And, we manufactured 200, 000 square meter of prefabricated steel building monthly for post-Wenchuan Earthquake reconstruction. Our daily capacity is large 5, 0000 square meter and this is how we manage it:

1) 200, 000 square meter of factory space

2) 10 production lines for our prefabricated building series, 960 workers

3) 200 workers in charge of overseas construction

4) Our sales representatives can reply to your inquiries within eight hours in English, French and Japanese.

5) Two hundred workers oversee overseas construction.

6) We passed quality tests by India Adani Power, Hyundai Steel, China Construction Group, China Railway Construction Group and other biggest companies in the world.

3. Project case- Heavy Steel Structure Building in Qingdao, 60, 000 SQM:

The Project - metallurgical automatic transmission equipment assembly base steel structure project. Located in Qingdao China High-tech Zone, total span is 120 meters, total length is 198.1 meters; eave height is 13.2 meters; the ridge height is 18.6 meters.

1) Trims,flashing: color steel sheet;

2) Gutter: color steel sheet;

3) Downpipe: PVC;

4) Door: sandwich panel door;

5) Window: Aluminium window( single glass)

This project is the national important investment project, the government, 3rd party QC consultant and the owner track the quality and progress very strictly in the whole process, finally they are satisfied with our quality and performance, and issue 5% extra bonus for our one month advance delivery which save them too much cost and make their production beginning earlier.

4. We found international surface treatment system for the metal building installation ( made of steel frame ) :

We got NACE 1 and 2 level certificate as per American standard.

We build professional enclosed shot blasting workshop, enclosed sand blasting room, 34000m2 fully-enclosed painting workshop and 20, 000 m2 enclosed packing workshop.

5. Our seaworthy packing system for metal building installation ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) How can I install these metal building installation ( made of steel frame ) together as a building after cargo arrived ?

Normally, most clients choose to install the steel building structure frame themselves or ask local technical engineer for further instruction.

If local technical support is not available or cost too much, we could also provide technical support engineer cross over-seas for installation guide even with our installation engineering team.

2) How to maintain my metal building installation ( made of steel frame ) years of using ?

metal building installation ( made of steel frame ) are built for long-time, reliable, steady usage purpose, the maintenance process is easy to operate and complete, most our product can live 10-15 years with minimal maintenance work like gel filled and paint spray. We will keep tracking the usage performance of our products and provide maintenance instruction for our clients.