|

Shandong Huaxing Steel Structure Co., LTD.

|

steel building structures made of H steel column wide-span to Liberia customer

| Price: | 1000.0 USD |

| Payment Terms: | L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Components will be packaged by steel pallet

2. Material: steel frame, sandwich panel, Q235

3. Building Type: warehouse, workshop, Agricultural

1. components and materials of the steel building structures ( made of steel frame ) :

Main structure | Welded H section , Lattice structure , Tubular column or beam , space frame etc |

Purlin | C Section Channel or Z Section Channel |

Roof Cladding | Sandwich Panel or Corrugated Steel Sheet with Fiber Glass Wool Coil |

Wall Cladding | Sandwich Panel or Corrugated Steel Sheet |

Tie Rod | Circular Steel Tube |

Brace | Round Bar |

Column & Transverse Brace | Angle Steel or H Section Steel or Steel Pipe |

Knee Brace | Angle Steel |

Roof Gutter | Color Steel Sheet |

Rainspout | PVC Pipe |

Door | Sliding Sandwich Panel Door or Metal Door |

Windows | PVC/Plastic Steel/Aluminum Alloy Window |

Connecting | High Strength Bolts |

Packing | Decided by you , loaded into 1X 40ft GP , 1X20 ft GP , 1X40 ft HQ |

Drawing | We can make the design and quotation according to your require or your drawing |

2. What we could do for you:

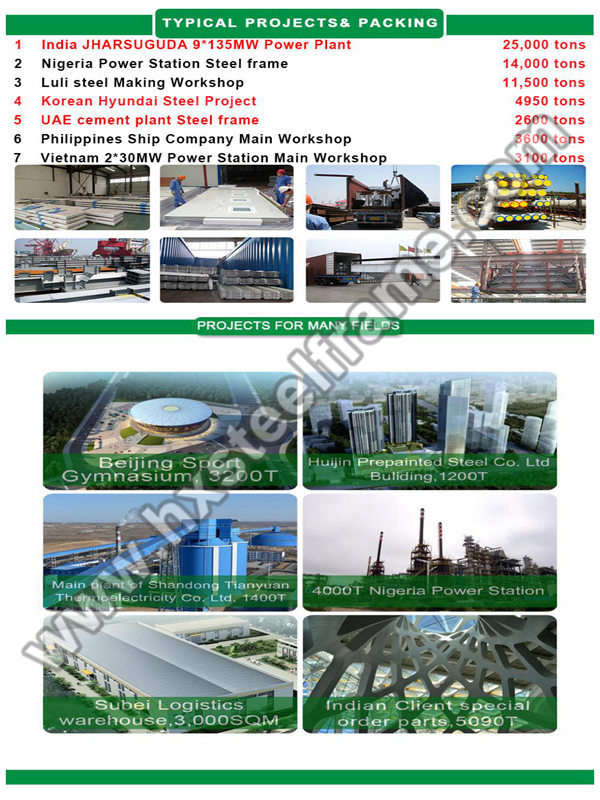

We specializing in steel structure design, manufacturing, installation and sale and featuring advanced technology. Taking the advantages of rich experience in management and cutting-edge technology in steel structure industries, based on production management system, we have established an effective interior production and operation system.

We can make almost all types of land based steel structure products, including steel workshop, warehouse, steel building structures ( made of steel frame ) , high rise steel building, etc. It is making efforts to explore the markets at home and abroad with a brand name of quality products to boost the development of the steel structure market and products in China.

3. Project case- Philippines Prefabricated Cold Storage Warehouse, 2013, 2900 tons:

Main steel frame:

Steel beam & column: Q345, Welded H beam

Wind-resistant column: Q345, Welded H beam

Secondary frame:

Roof purlin: Z250*75*20*2.2

Ceiling purlin: C120*50*20*2.2

Wall purlin: C180*70*20*2

Tie bar: 102*2

Vertical & horizontal bracing: 20

Kneel-bracing: L504

Purlin bracing: Q235, 12

Sleeves tube: Q235, 32*2.5

Roof system:

Type V930 pu panel 0.5/100/0.6mm Pu panel

Wall system:

Type v930 panel 0.5/100/0.6mm Pu panel

This project is invested by the government, before the client issue the order, the client, government, and the 3rd party consulting company visited us for 4 times. Finally after compare the advantage between 6 suppliers, they choose us. The later result prove their selection are wise. We finish the project 20 days before the delivery end date, and with good quality.

4. We found international surface treatment system for the steel building structures ( made of steel frame ) :

We got NACE 1 and 2 level certificate as per American standard.

We build professional enclosed shot blasting workshop, enclosed sand blasting room, 34000m2 fully-enclosed painting workshop and 20, 000 m2 enclosed packing workshop.

5. Our seaworthy packing system for steel building structures ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) How can I install these steel building structures ( made of steel frame ) together as a building after cargo arrived ?

Normally, most clients choose to install the steel building structure frame themselves or ask local technical engineer for further instruction.

If local technical support is not available or cost too much, we could also provide technical support engineer cross over-seas for installation guide even with our installation engineering team.

2) How to maintain my steel building structures ( made of steel frame ) years of using ?

steel building structures ( made of steel frame ) are built for long-time, reliable, steady usage purpose, the maintenance process is easy to operate and complete, most our product can live 10-15 years with minimal maintenance work like gel filled and paint spray. We will keep tracking the usage performance of our products and provide maintenance instruction for our clients.