|

Shandong Huaxing Steel Structure Co., LTD.

|

metal arch buildings and steel building packages outdoor hot sale in Honduras

| Price: | 1000.0 USD |

| Payment Terms: | L/C,L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Product code: AISI, ASTM, BS, DIN, GB, JIS

2. Engineers' guidance on-site is available

3. Wide span: single or multiple span, max span 36m

1. Information for metal arch buildings ( made of steel frame ) :

Standard | ASTM , BS , DIN , GB , JIS |

Material Grade | Q235 & Q345 ( S235JR & S355JR ) |

Dimensions | Yours requirements |

Place Of Origin | Shandong China ( Mainland ) |

FOB Price | US $ 20 - 150 / Square Meter |

Port | Qingdao |

Minimum Order Quantity | 100SQM |

Supply Ability | 1000 Ton / Tons per Month |

Payment Terms | L/C ,T/T |

Quality Control | The third party , SG S , ASIA INSPECTION all accept |

Delivery Term | Within 20 days after signing contract |

Packaging | According yours requirement , usually bundle with steel strip |

Delivery Container | 20'GP , 40'GP , 40'HQ , 40'OT |

Our Experience | Have exported for 13 years , clients from all over the world |

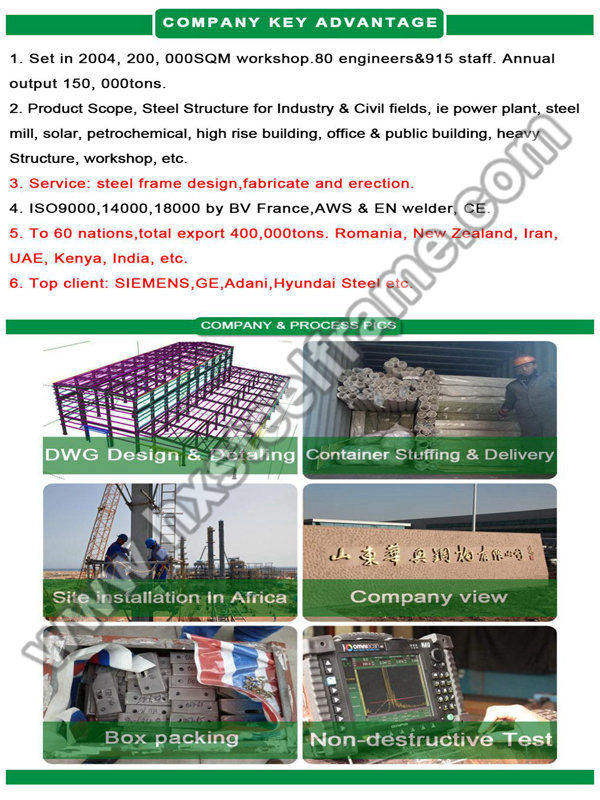

2. Who we are:

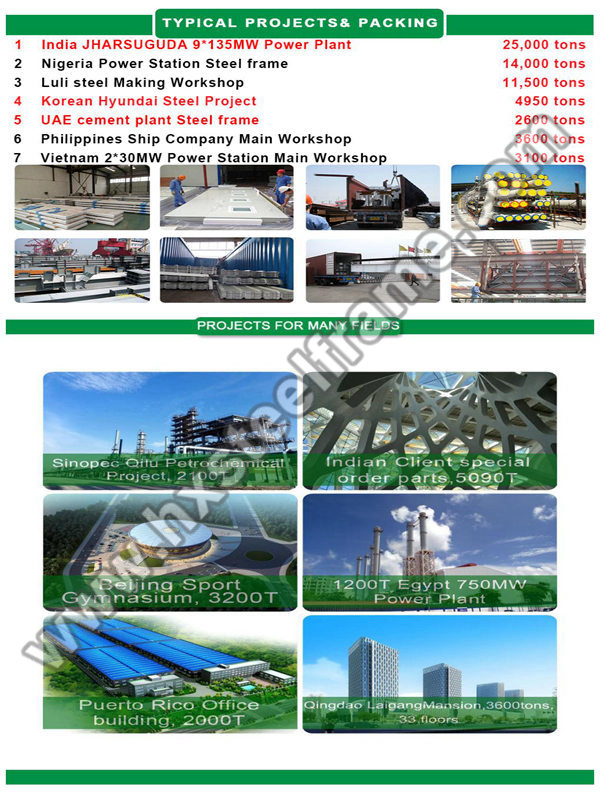

We are mainly specially steel structure construction company undertaking the design, fabrication, assembly, and after-sales service of various types of metal arch buildings ( made of steel frame ), civil construction, heavy steel structures, stadiums, industrial workshops and warehouse building, steel structures high-rise building.

Now we have 3 heavy steel production line, six light steel production lines, 3 H-beam secondary processing lines, and advanced digital-controlled multi-head cutting machine,automatic submerged arc welding machine, assembly machine, calibrating machines, full-automatic shot blasting machines, totaling 200 equipment or more.

3. Project case- Uganda Steel Coil Processing Plant:

Detailed introduction

Project Description: 30x 120M

Project Type: Gable frame PEB structure with office mezzanine building, Stairs, Platform, etc

Time: Oct. 25, 2012

Location: Uganda

Description:

Site anchor bolt installation all ready finished as planed and all engineering are made as per existing plan to save the client' s investment cost of foundation preparation. We supply the steel structure and panel system within 20 days, which make client very satisfied and we found continuous cooperation with this client after the 1st order.

4. We found international surface treatment system for the metal arch buildings ( made of steel frame ) :

We got NACE 1 and 2 level certificate as per American standard.

We build professional enclosed shot blasting workshop, enclosed sand blasting room, 34000m2 fully-enclosed painting workshop and 20, 000 m2 enclosed packing workshop.

5. Our seaworthy packing system for metal arch buildings ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Is there a clear service life of your metal arch buildings ( made of steel frame ) ? If have, how long ?

Under conventional climate and environment, steel structure whole building 30 years, main structure 50 years, protecting system 30 years.

2) What designs do you have in different climates? How can the metal arch buildings ( made of steel frame ) adopt to different climates?

Strong wind region: improve the wind-resisting ability of the internal structure.

Cold region: increase the thickness of the wall, or use good insulation material, improve anti-pressure ability of the structure.

High corrosion region: use corrosion resistant material, or paint anti-corrosive coating.