|

Shandong Huaxing Steel Structure Co., LTD.

|

prefab shop buildings made of steel frame work hot Sell sale to Djibouti

| Price: | 1000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Accessories packed& protected by plastic paper

2. Resistant to 8-9 earthquake grades.

3. Fully support in installation & guidance

1. Characteristics of prefab shop buildings ( made of steel frame ) :

Steel structure is widely used as warehouse , factory , hotel , church , garage etc . It is durable , economic and environmental .

Main Grade : Q345B , Q235B

Standard : ISO9001 : 2008

We are a Factory-direct provider of all kinds of steel structure buildings and material plant . We specialize in design , fabricate construction , install and related technology guide . Our competitive price and high quality have got customers from all over the word .

Applications :

Used as Steel workshop / warehouse / shed , Exhibition Hall , Office buildings , Garage , Multi-story building , Hanger , Agricultural storage , Logistic centers , and all kinds of steel materials etc .

Specifications :

Main Steel : Q345B , Q235B

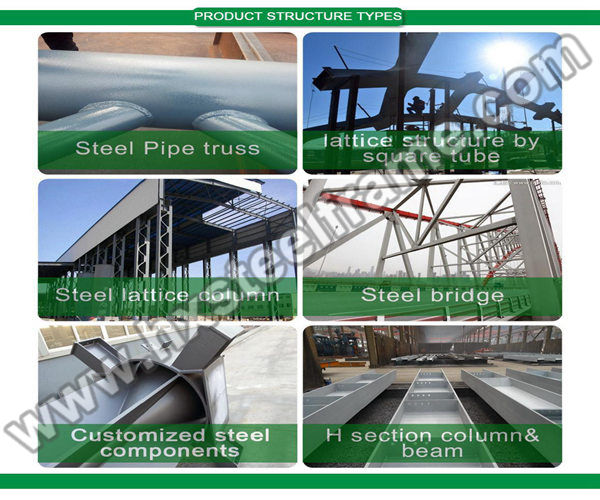

Column&Beam : Welded or Hot rolled H-section

Wall&Roof : EPS , Rock wall , PU sandwich , corrugated steel sheet

Door : Rolled up door or Sliding door

Window : Plastic steel or Aluminum alloy window

Surface : Hot dip galvanized or painted . ( all colors we can do )

Crane : 5T , 10T , 15T , etc .

2. Company Brief:

Founded in Shandong, we are one of the most powerful enterprises of steel building and steel structure in China.

Area of Main factory: 360,000 square meters and the 200,000 square meters' workshops.

Total number of staff: 960 persons, details are as follow:

Number of Admin Staff: 140.

Number of Marketing and Sales: 102.

Number of Architectural Designers: 58

Number of In Line QC: 38.

Number of regular workers for production and installation of prefab shop buildings ( made of steel frame ) : 600

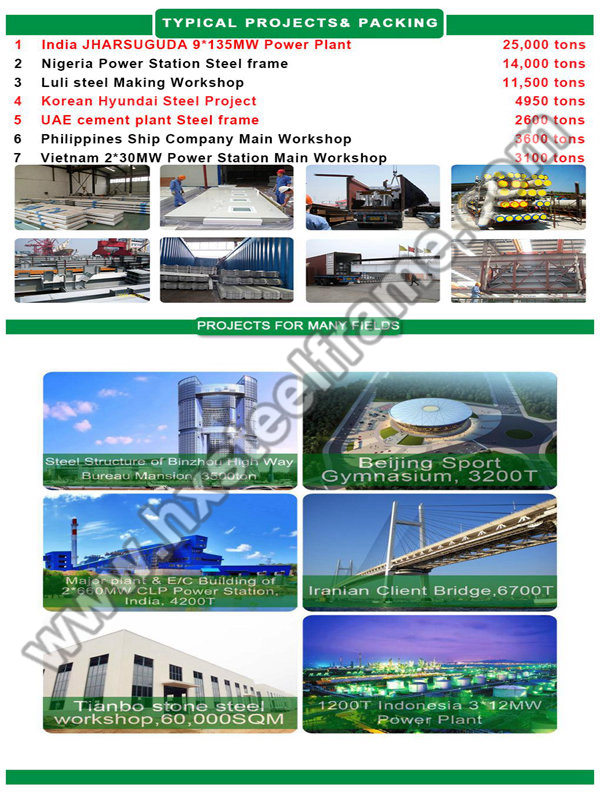

We have the experience to do the big projects with the top rank construction company in the world, we are always showing our best service and professionalism, and we have exported the steel structure buildings to more than 110 countries.

3. Project case- Argentina Steel Structure workshop Building:

We are the largest steel structure building materials supplier and manufacturer in Shandong, China.

This steel structure building used for workshop built in 2010 year for our Argentina Customer.

Project Conditions:

1) Size: 5930M2

Main workshop area 80m long* 60m wide* 9m Eaves height( ridge height 10m)

Affiliated workshop area: 1130 square meter.

2) Wall & roof material: V-960 light steel sandwich panel

3) Thermal Insulation: 50mm EPS foam, 12kg/ m3

4) Wind load: 0.79kn/ M2

5) Crane: 8 cranes( lifting capacity: 2 ton)

6) Windows and doors: electrical rolling window&doors, aluminium alloy

4. Hardware Advantage for prefab shop buildings ( made of steel frame ) :

Factory I covers area of 253 mu( 168, 751SQM) , with 18, 000SQM of heavy structure workshop, 36, 000SQM of light structure workshop, 16, 000SQM of non-standard product workshop, 3000SQM of pre-fabricated piping workshop and 40, 000SQM of finished product stacking yard.

Factory II covers an area of 1000 mu( 667, 000 SQM), include 30, 000SQM heavy structure workshop( lifting capacity 200T) , 34, 000SQM non-standard product workshop, 34, 000SQM of enclosed painting workshop, 20, 000SQM of packing workshop and 30, 000SQM of finished product storage yard have been constructed.

Our heavy structure workshop of factory II is specially designed for fabricating all kinds of super heavy structure, the crane are equipped with max elevating capacity of 200MT.

5. Our seaworthy packing system for prefab shop buildings ( made of steel frame ) :

We found mature exporting packing and stuffing system:

With more than 300000tons exporting experiences, we adopt enclosed transportation to avoid damage to components caused by rough loading& unloading in delivery process. It not only guarantees components quality, but also saves the delivery cost for clients.

To improve the container delivery efficiency, we introduced advanced container stuffing equipment from Germany in 2012, which could make us finish one 40 feet container stuffing within 2 minutes.

6. FAQ:

1) Do you offer service for installation ?

Re: We will give detailed installation drawings and direction info for free. And if you need, we could also send engineers as installation director even a team.

2) What should I provide to build a prefab shop buildings ( made of steel frame ) ?

A: So easy! Design drawing would be a better reference for us. However, you will

never mind if you don't have any. Simply notify us your requirements, such as the

area, wind load, usage of the warehouse etc. Before long, you' ll possess an amazing design.

If you have any new need, please provide your drawing paper or technical parameter for us reference, we will quote for you more precisely and accordingly.

3) Is the prefab shop buildings ( made of steel frame ) erection quick ?

Yes, Steel beam, steel column, crane beams, purlins, support, wall beam, they are prepared in a factory, they are installed only need to connect with bolt on site, this installation is quick and convenient, Only need to provide the installation drawings.