|

Shandong Huaxing Steel Structure Co., LTD.

|

Prefab Steel workshop steel column construction reduce foundation cost

| Price: | 1000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Wall& roof panels: be packed by plastic film

2. Workshop Column: Welded/ Hot rolled H-section

3. Product meet national/ international standar

1. How to build a Prefab Steel workshop ( made of steel frame ) , please check the following table :

Design Data ( important ) | live load on roof ( KN / M2 ) wind speed ( KM / H ) snow load ( KG / M2 ) if have |

Size ( important ) | width length height roof slope |

Type | single slope or double slope muti slope or single span single floor or two floors |

Inter column | 5m , or 6m …. |

Windows & Door | 1 . quantity 2 . size 3 . Location 4 . PVC or aluminum |

Column &Beam | straight cross-section OR Variable cross-section |

Roof & Wall Panel | 1 . Colorful corrugated steel sheet 0.326~0.8mm thick , YX25-210-840 ( 840mm wide ) 3 . sheet+glass fiber(thick 50mm~200mm) |

Purlin | 1 . C purlin 2 . Z purlin |

Accessories | Do you need the skylight belts , Ventilators,down pipe , out gutter etc ? |

Surface Treatment | Shot blasting with anti rust paint or hot dip galvanize |

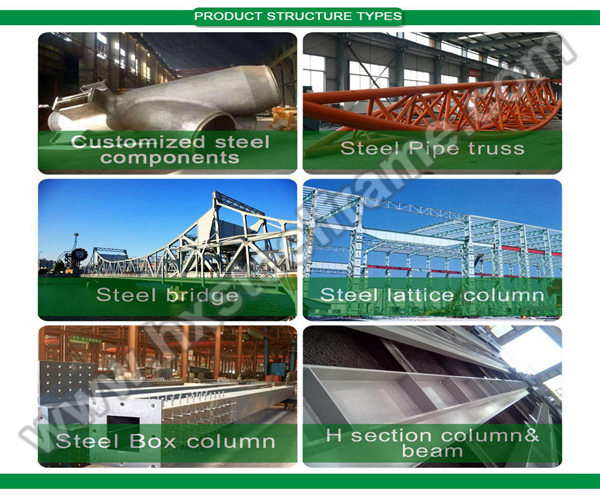

2. Wide Fields of Steel Structure be used:

1) Industrial steel structure warehouse, Prefab Steel workshop ( made of steel frame )

2) Steel workshop / hangar / garage

3) prefabricated steel structure shed, Exhibition Hall, Office buildings

4) Garage, Musty-story building, Agricultural storage

5) Logistic centers and all kinds of steel structure buildings etc

3. Some of OUR WORKSHOP/ WAREHOUSE PROJECTS:

1) AREVA Transformer Factory Project:

Covering an area totaled 33, 842 sq.m, the program consumed steel in 4299 tons, the column height is 31-33 m, and the inside is installed with the bunk bed traveling crane with the maximum hoisting capacity in 400 tons.

2) NEW ZEALAND Barns / Grain Warehouses:

light gauge steel structure with cold bended profiles.

3) BOLIVIA Cement Plant:

Steel consumption: 3, 655 tons in the first phase, 7200 tons in the second phase.

4) LDK Polysilicon Public Project:

Was generally contracted by FLR CO., LTD, the total steel consumption volume for Phase I project reached over 3000 tons and this program was in a high-rise steel structure of 4-7 floors.

4. Trial Assemblies to ensure smooth erection of Prefab Steel workshop ( made of steel frame ) on project site:

Our plant is fitted out with large working areas for major assembly work of steel structures and oversized built-up components

In order to ensure the optimal installation of the steel structures on-site, trial assemblies of various and unique steel pieces with complex geometry forming part of a built-up component, are performed in the plant prior to their delivery to site. In addition to validating the quality of the design, the compliance with engineering parameters and fabrication accuracy, these trial assemblies add great value for the client since they mean potential time and cost savings with regard to installation work on site.

To successfully carrying out trial assemblies of large steel components, our fabrication complexes have been fitted out with large production areas and state-of-the-art equipment as well as measurement method, which are integrated in Tekla Structures 3D software, thus ensuring the quality control of its products.

5. Advantage of the Prefab Steel workshop ( made of steel frame ) :

1) Excellent Material Quality

The steel structure building can resist scratch, fading and are moisture-proof. They are designed to withstand harsh weather conditions, and provide long-term durability, which are fit for many uses.

2) Larger Internal Storage

These steel structure building provide larger internal space than many other sheds. They can be used as a workshop, light industry factory, garage, or general small industrial storage.

3) Easy Assembly

Compared with other metal sheds, steel structure building are fast to build with installation instructions.

4) Maintenance free

In general, the steel structure building do not need repairing.

6. FAQ:

1) Q: How could I control the cost of building a Prefab Steel workshop ( made of steel frame ) ?

A: Firstly, the designing scheme should be mutually discussed and then accepted. Then, the kinds of building materials should be confirmed since different types and qualities make various prices. After that, we will send you a detailed quotation.

2) Q: How Long does it take to build a Prefab Steel workshop ( made of steel frame ) ?

A: It depends on the size of the warehouse. Generally, the construction period of is 1 month of a 2000-square-meter workshop by a construction team of 8-10 people. It only costs 2-3 weeks to build the steel structure frame.

3) Q: Is it difficult to build a Prefab Steel workshop ( made of steel frame ) ?

A: totally not, you can let your local teams build it according to the construction drawings and erection guiding video provided by us.