|

Shandong Huaxing Steel Structure Co., LTD.

|

built-up steel column formed prefab steel garage cost-saving to Paris customer

| Price: | 1000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. 100% QC inspection before shipment

2. EPS sandwich panel( for wall, roof, floor)

3. Main Steel: Q345, Q235, Q345B, Q235B etc.

1. Typical Surface treatment for Steel building ( made of built-up steel column ) :

Surface Treatment |

Hot dip galvanize |

Standard : JIS , DIN , ASTM B695 - 2000 |

Hot dip galvanizing hole cutting good looking on surface |

Galvanizing process : Steel structural components → Degreasing → Rinsing→ Pickling → Rinsing → Fluxing → Galvanizing → Quenching → (Passivation) → Inspecting → Finished Product |

Paint |

1 . Primer paint one coat 20 - 30 um |

2 . Middle paint two coat 40 - 60 um |

3 . Finish paint one coat 20 - 30 um Paint type : 1 . red primer 2 . zinc primer 3 . Alkyd primer |

2. Applications of steel structure:

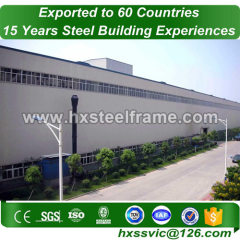

Structural steel fabrication have become increasingly and widely used at the workshops, warehouse, Steel building ( made of built-up steel column ) and other industrial and civil architectures. For example, single-span and multi-span gantry light-frame structures, exhibition Hall, industrial steel frame, Office buildings, Garage, Multy-story building, Hanger, Agricultural storage, Logistic centers, and all kinds of steel construction, etc.

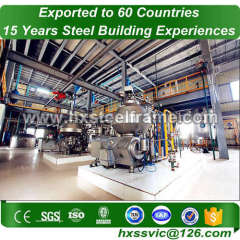

3. Project case- Congo Steel Sheet Making Factory project, 2016:

Project Overview:

Beam & Column structure with large span curved cellular rafters. Package included structural steel work, stairs, balustrading and steel decking.

Main Contractor: MAPA Group

Engineer: Five Consulting Engineers

Tonnage: 2800

Completion Date: 2016

Due to the tight schedule of this project, to save the time and improve the container delivery efficiency, we use our container stuffing equipment from Germany, which could make us finish one 40 feet container stuffing within 2 minutes. The client and owner are all surprised to see our container stuffing system. What is more important and make them amazing, the goods are 100% brand new and without any damage after reach to project site. This help the owner get many prize from the local government.

4. Our complete flow Service for the Steel building ( made of built-up steel column ) :

1) Before sales of prefab steel structure building: We will provide you the most suitable product, guide our customer to find the products you most needed, assure that our customer can pay least money and get most return.

2) Technical Consultation and Suggestion before Construction: We provide professional consultation and suggestion service for customers' project evaluation about how cost and duration.

3) After sales service of prefab steel structure workshop: Our company insist to use the best quality to win more customer, if there is any question after receive the products, we will provide the best solution to solve the problem our customer have.

5. Packaging & Shipping for Steel building ( made of built-up steel column ) :

1) Using container:

container of 20 feet, and container of 40 feet

2) By sea for batch goods, for container or bulk-cargo ship, port receiving.

3) Customers specifying freight forwarder or negotiable shipping methods

4) All of the steel column& beams ends and plates will be packed by the blanket to protect them from the crash in the container during the shipment.

5) To make the loading and unloading more efficiently and saving the delivery cost, 40' OT is preferred to loading the steel frames.

6) All the wall and roof panels will be filmed by two sides and fixed stably in the 40HQ container.

7) All the windows and doors will be protected by the bubble rapping papers and fixed stably in the container.

6. FAQ:

1) How about the delivery time of the Steel building ( made of built-up steel column ) ?

Reply: Usually, 5000SQM or 800tons steel building within 45-60 days after the order confirmed, also depends on the fabrication quantity.

2) What makes you different from other manufacturers ?

We believe our service department has the experience and knowledge to safely service your need for structural steel construction, such as industrial workshop, light steel warehouse, container house, Steel building ( made of built-up steel column ). We have trained service technicians who will be able to help your erection, and have been providing our customer's an effective service solution.

3) Can I customize my Steel building ( made of built-up steel column ) ?

Answer: We have as a wide variety of finishes and features that will satisfy your personal taste and needs. Please contact our sales to explain some detail you want to customize the warehouse.