|

Shandong Huaxing Steel Structure Co., LTD.

|

erection steel structure and welded steel structures well welded for Oman

| Price: | 1000.0 USD |

| Payment Terms: | L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Standard accessary: put into boxes or bag

2. Fully support in installation & guidance

3. Products passed through strict quality checks

1. Fill the Table below and Sent It to Us, to Get Your Free Proposal for Steel building ( made of erection steel structure ) :

Your location | Country ________ State ________ City _______ Postal code ________ |

Size | Length ________ meter Width ________ meter Height ________ meter |

Storey | Storey number ________ |

Wind Load | ________ km / hour |

Snow Load | ________ kn / m² |

Anti - earthquake | ________ magnitude |

Roof Normal Payload | ________ kg / m² |

Brick wall needed or not | If needed , brick height ________ |

Thermal insulation if needed | If needed , EPS panel , PU sandwich panel Glass wool panel , Rock wool panel are optional . If needed , normal pre-painted steel tile will be used for your project . |

Crane if needed | If needed , _____ units , max lifting weight ____ tons ; max lifting height _____ m |

Storage Cargo condition | If additional requirement for anti-corrosive |

2. Company In Brief:

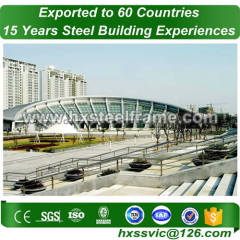

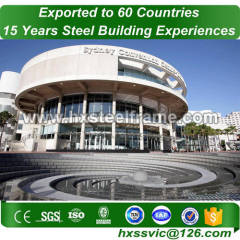

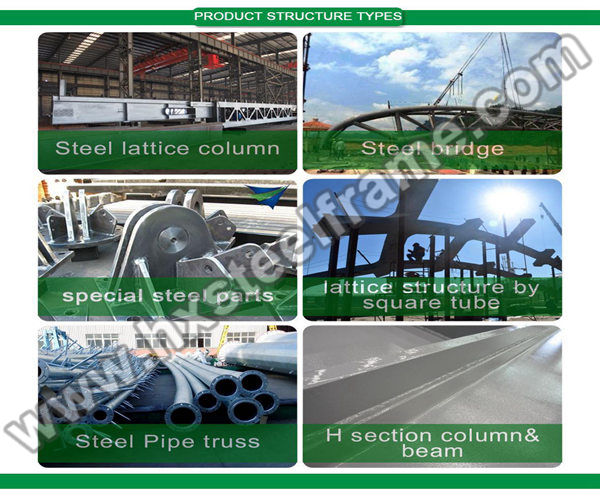

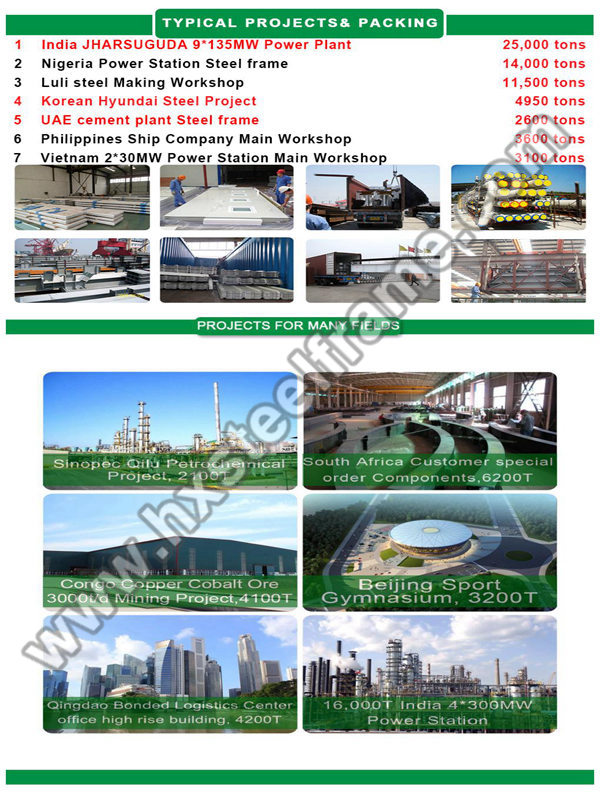

We specializes in providing complete solutions for high-quality steel structure products including: design, fabrication and erection of. Besides pre-engineered buildings, nowadays, we have developed heavy structural industry and commercial projects that aim to provide customers full structures such as workshops, warehouses, plazas, exhibition centers, supermarkets, railway stations, airports and so on …

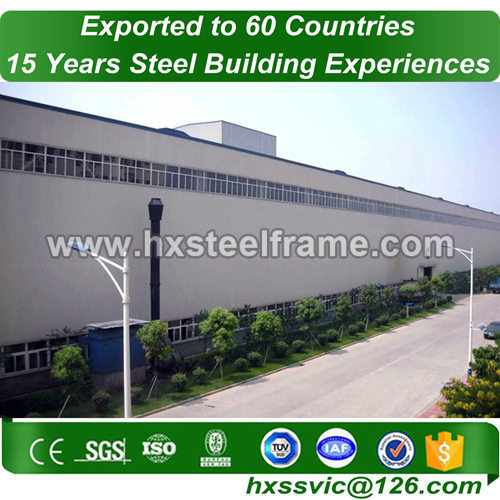

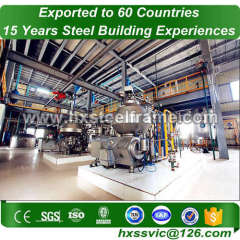

With a well-trained workforce of over 1, 000 professional staffs, quality management system ISO 9001:2008, ISO 14001: 2004, OHSAS 18001: 2007 and a 200, 000 m2 factory with high technology automatic production facilities, we delivers the optimal solution, high-quality products and perfect services for your project.

Our top serviced client include SIEMENS, GE, India Adani Power, Hyundai Steel etc.

3. Project case- Structural Steel Logistics Warehouse:

This logistics warehouse is constructed for Hidu, it' s located in Qingdao, China, total area is 40, 000m2.

Our company takes 22 days in total to finish the area of 20,000m2, it' s a miracle in this field of steel structure construction, and we got high reputation from our customer.

1) Roof use V760 type 0.6mm steel sheet with 75mm glass wool and attaching veneer.

2) Wall use V840 type 0.6mm steel sheet

3) Skylight panel on roof

4) Ventilator on roof

4. Service we provided for the Steel building ( made of erection steel structure ) :

1) Pre-Sales Service:

Inquiry and consulting support.

View our Factory.

2) After-Sales Service:

Training how to install the steel structure, training

Engineers available to do some instruction of steel structure overseas.

5. Packaging & Shipping for Steel building ( made of erection steel structure ) :

1) Using container:

container of 20 feet, and container of 40 feet

2) By sea for batch goods, for container or bulk-cargo ship, port receiving.

3) Customers specifying freight forwarder or negotiable shipping methods

4) All of the steel column& beams ends and plates will be packed by the blanket to protect them from the crash in the container during the shipment.

5) To make the loading and unloading more efficiently and saving the delivery cost, 40' OT is preferred to loading the steel frames.

6) All the wall and roof panels will be filmed by two sides and fixed stably in the 40HQ container.

7) All the windows and doors will be protected by the bubble rapping papers and fixed stably in the container.

6. FAQ:

1) Is there a clear service life of your Steel building ( made of erection steel structure ) ? If have, how long ?

Under conventional climate and environment, steel structure whole building 30 years, main structure 50 years, protecting system 30 years.

2) What designs do you have in different climates? How can the Steel building ( made of erection steel structure ) adopt to different climates?

Strong wind region: improve the wind-resisting ability of the internal structure.

Cold region: increase the thickness of the wall, or use good insulation material, improve anti-pressure ability of the structure.

High corrosion region: use corrosion resistant material, or paint anti-corrosive coating.