|

Shandong Huaxing Steel Structure Co., LTD.

|

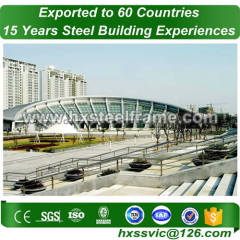

conventional steel structures metal building systems fireproof

| Price: | 1000.0 USD |

| Payment Terms: | L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. The enterprise been verified by BV and SGS

2. Span:single span or multi span

3. Foundation connected by anchor bolt

1. components and materials of the Steel building ( made of conventional steel structures ) :

Main structure | Welded H section , Lattice structure , Tubular column or beam , space frame etc |

Purlin | C Section Channel or Z Section Channel |

Roof Cladding | Sandwich Panel or Corrugated Steel Sheet with Fiber Glass Wool Coil |

Wall Cladding | Sandwich Panel or Corrugated Steel Sheet |

Tie Rod | Circular Steel Tube |

Brace | Round Bar |

Column & Transverse Brace | Angle Steel or H Section Steel or Steel Pipe |

Knee Brace | Angle Steel |

Roof Gutter | Color Steel Sheet |

Rainspout | PVC Pipe |

Door | Sliding Sandwich Panel Door or Metal Door |

Windows | PVC/Plastic Steel/Aluminum Alloy Window |

Connecting | High Strength Bolts |

Packing | Decided by you , loaded into 1X 40ft GP , 1X20 ft GP , 1X40 ft HQ |

Drawing | We can make the design and quotation according to your require or your drawing |

2. About us:

Have you ever experienced Complicated & Tedious to communicate with many of different factories for your wide range products demand for your projects? Are you tired and bored with your suppliers after the order confirmed? No worries. We can help you to solve all these problems. You only need to sit in your office. All of the other things hand over to us.

We are one Stop Shop for all of your steel building materials. We offer various types of steel structure, steel building, workshop, steel warehouse etc at competitive price.

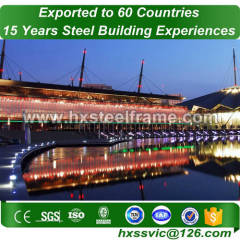

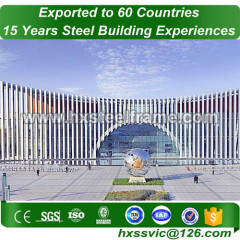

We have been in the building field for more than 10 years earned our reputation as one of the Chinese's leading suppliers of construction metal products. We mainly worked with the Developer, Contractor, Designer and the Architect. In the following famous projects we are all involved as VIP supplier: Shanghai World Expo, Shanghai Disney Resort, South Korean Hyundai Steel Project 2950T.

We have our own Design Team and Quality Control Center. You only need send us your projects' Plan drawings then we make the solutions for you.

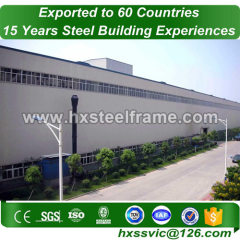

3. Project case- Industry Prefabricated Steel building:

Argentina prefabricated steel workshop project was done in the year of 2013, finished installation in the year of 2014. Total area of this workshop is 5, 700 square meters. Main workshop size is 84X 60X 9m, totally 4 spans, 15m per span with one 3ton crane in each, lifting height of the crane is 6m. Two accessory houses on both sides of the main workshop.

4. Hardware Advantage for Steel building ( made of conventional steel structures ) :

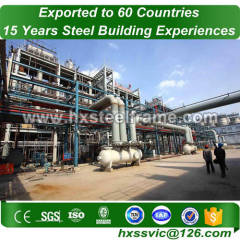

Factory I covers area of 253 mu( 168, 751SQM) , with 18, 000SQM of heavy structure workshop, 36, 000SQM of light structure workshop, 16, 000SQM of non-standard product workshop, 3000SQM of pre-fabricated piping workshop and 40, 000SQM of finished product stacking yard.

Factory II covers an area of 1000 mu( 667, 000 SQM), include 30, 000SQM heavy structure workshop( lifting capacity 200T) , 34, 000SQM non-standard product workshop, 34, 000SQM of enclosed painting workshop, 20, 000SQM of packing workshop and 30, 000SQM of finished product storage yard have been constructed.

Our heavy structure workshop of factory II is specially designed for fabricating all kinds of super heavy structure, the crane are equipped with max elevating capacity of 200MT.

5. Packing & Delivery for Steel building ( made of conventional steel structures ) :

For Main Components: Put steel structure components on a steel pallet and tie up the frame part together by packing strap with wood beam and cardboard, then load into container by crane or forklift

For cladding: Plastic film wrap the roof and wall corrugated single steel plate.

but for sandwich panel will load into container piece by piece

This package is to protect the goods from damage, during the transportation.

Delivery:

Load into 40/ 20GP, 40HQ, 40OT or Bulk carrier.

Delivery Time: 15 to 30 days after the receiving deposit or according to client' s requirements.

6. FAQ:

1) How to control the quality of your Steel building ( made of conventional steel structures ) ?

a. quality of the design: think about possible problems in advance and provide a high quality design solution.

b. quality of the raw material: choose the qualified raw material from the top steel mill in China.

c. quality of the production: precise manufacturing technique, experienced workers, strict quality inspection.

2) How to deal with quality problems of your Steel building ( made of conventional steel structures ) ?

Warranty is 2 years. Within the warranty period, we will responsible for all quality problems caused by production.