|

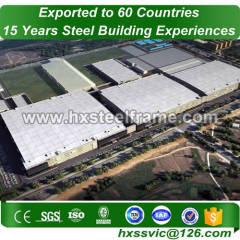

Shandong Huaxing Steel Structure Co., LTD.

|

heavy metal fabrication formed steel buildings low cost sale to Congo

| Price: | 1000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. 100% QC inspection before shipment

2. In-house QA Laboratory to ensure quality

3. Guarantee: The main structure over 35 to 50 years

1. Typical Surface treatment for Steel building ( made of heavy metal fabrication ) :

Surface Treatment |

Hot dip galvanize |

Standard : JIS , DIN , ASTM B695 - 2000 |

Hot dip galvanizing hole cutting good looking on surface |

Galvanizing process : Steel structural components → Degreasing → Rinsing→ Pickling → Rinsing → Fluxing → Galvanizing → Quenching → (Passivation) → Inspecting → Finished Product |

Paint |

1 . Primer paint one coat 20 - 30 um |

2 . Middle paint two coat 40 - 60 um |

3 . Finish paint one coat 20 - 30 um Paint type : 1 . red primer 2 . zinc primer 3 . Alkyd primer |

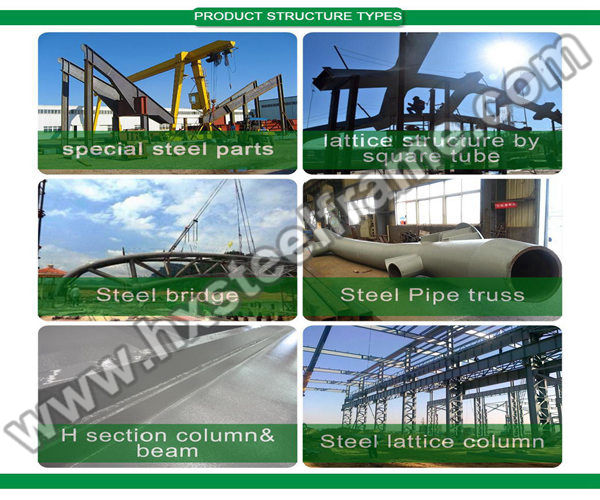

2. Our products scope include:

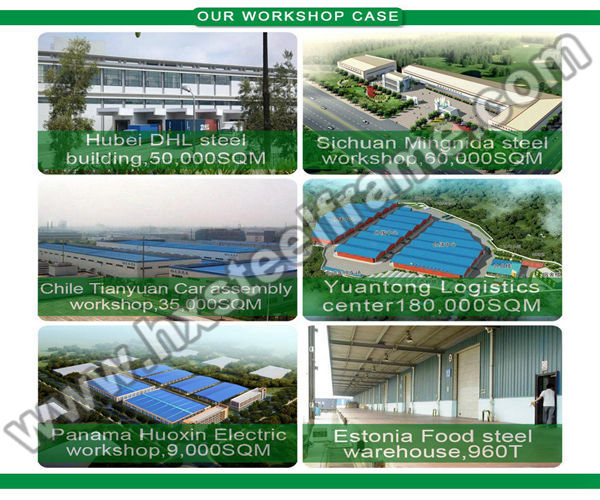

Single layered light and MID-sized workshops and warehouses, Steel building ( made of heavy metal fabrication ), single layered heavy duty workshops, wide-span public buildings, high-layered and super high-layered buildings, muti-layered industrial workshops, office buildings and houses, bridges, wide-span highway bridges and bridges in city, viaducts; industrial platform and support; structures that can be dismantled and transported, etc

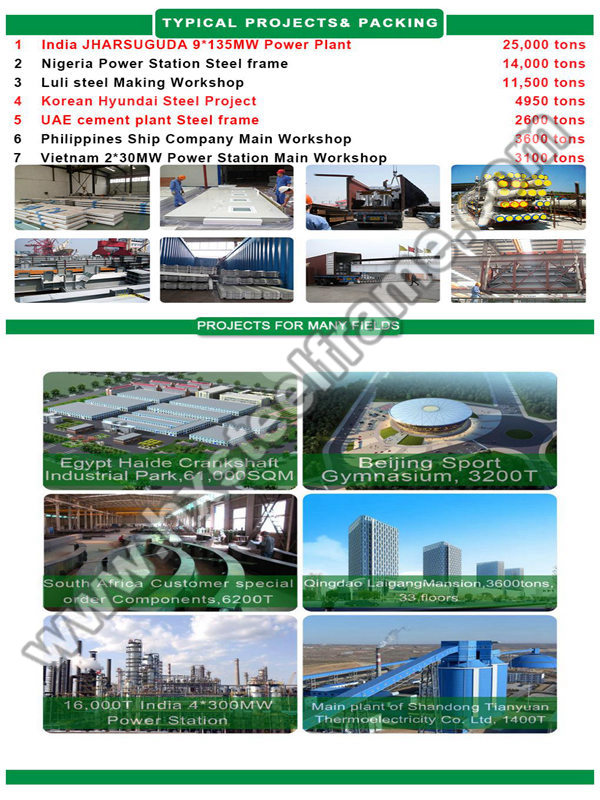

3. Project case- South Africa Light Pre-engineered Building, 7000SQM, 2011:

South Africa workshop project

usage: steel pipe production workshop

length 252M X width 27.5M X height 11M, with a crane of 30 ton, the crane sling height is 7M. The workshop adopt Frame bent structure, lattice form column. Roof and wall surface is single steel sheet, no heat insulation, the bottom of wall has brick wall that 800 mm height and aluminum windows that 1.8m height, skylight sheet on roof for lighting.

Client issue the order to us within 1 week after visit our factory, our hardware and ISO management system leave deep impression to them. Now, we have finished more than 6 orders for this client.

4. Certificates & Quality Management for the Steel building ( made of heavy metal fabrication ) :

We have ISO9000, 14000, 18000 by BV France, AWS& EN welder, CE etc to ensure our whole production progress controllable.

We also have systematic Quality Process and Progress Control documentation: Our fabrication process have been controlled by series of documentation and quality testing which are monitored and certificated by BV, SGS, SKM, JACOBES etc world-famous third party inspection organization.

5. Packaging & Shipping for Steel building ( made of heavy metal fabrication ) :

1) Using container:

container of 20 feet, and container of 40 feet

2) By sea for batch goods, for container or bulk-cargo ship, port receiving.

3) Customers specifying freight forwarder or negotiable shipping methods

4) All of the steel column& beams ends and plates will be packed by the blanket to protect them from the crash in the container during the shipment.

5) To make the loading and unloading more efficiently and saving the delivery cost, 40' OT is preferred to loading the steel frames.

6) All the wall and roof panels will be filmed by two sides and fixed stably in the 40HQ container.

7) All the windows and doors will be protected by the bubble rapping papers and fixed stably in the container.

6. FAQ:

1) How can I install these Steel building ( made of heavy metal fabrication ) together as a building after cargo arrived ?

Normally, most clients choose to install the steel building structure frame themselves or ask local technical engineer for further instruction.

If local technical support is not available or cost too much, we could also provide technical support engineer cross over-seas for installation guide even with our installation engineering team.

2) How to maintain my Steel building ( made of heavy metal fabrication ) years of using ?

Steel building ( made of heavy metal fabrication ) are built for long-time, reliable, steady usage purpose, the maintenance process is easy to operate and complete, most our product can live 10-15 years with minimal maintenance work like gel filled and paint spray. We will keep tracking the usage performance of our products and provide maintenance instruction for our clients.