|

Shandong Huaxing Steel Structure Co., LTD.

|

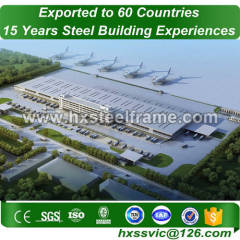

prefabricated structures formed steel bulidings professional sale to Paris

| Price: | 1000.0 USD |

| Payment Terms: | L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Customers or us specifying freight forwarder

2. Certification ISO9001: 2008, by BV France

3. QC:own high quality control or use third party

1. Product Details for Steel building ( made of prefabricated structures ) :

Main frame | ||

1 | Main steel structure

( columns and beams ) | 1 . Steel Q345 ( S355JR ) or Q235 ( S235JR ) H shape 2 . Straight cross-section or Variable cross - section |

2 | Sub steel structure | 1 . Material Q235 ( S235JR ) steel 2 . Bolt connections . Anti-rust painted or galvanized . 3 . Bracing :X - type or V - type or other type bracing made from angle , round pipe , etc 4 . Purlins : C or Z type : Size from C120 ~ C320 , Z100 ~ Z200 |

Maintenance system | ||

3 | Roof | Sandwich panel ( PU / EPS / fiberglass / rook wool ) or Colorful steel tile |

4 | Wall | Sandwich panel ( PU / EPS / fiberglass / rook wool ) or Colorful steel tile |

Doors | Steel rolling shutter or others | |

Windows | Alu. Alloy window , or others | |

Fitting | ||

7 | Edge Cover | Steel sheet 0.5mm thickness |

8 | Bolts | M24 , M22 , M16 embedded bolts , intensive bolts , galvanized ordinary bolts , high-strength bolts , etc |

9 | Others options | Day - lighting panel , Roof ventilator , Down pipe , Galvanized , Crane , sanitary Products , etc |

10 | Foundation | Cement and steel foundation bolts |

2. About us:

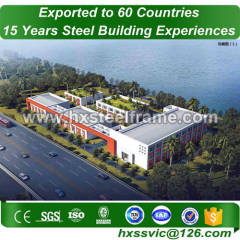

Our company commenced its operations in 2004, and pioneered the high-end metal building products market in China. We have been the first mover in China, right from workshop, high rise building, Steel building ( made of prefabricated structures ) etc to all kinds of pre-engineered buildings.

Today, we are a leading turnkey Pre-Engineered Steel building Construction Solution provider in China with integrated facilities for design, manufacture, logistics, supply and project execution capabilities for pre-engineered steel buildings. We holds a significant part of market share in Asia for metal building systems. We works in close association with industry leaders in project development and construction, providing support to critical industrial, commercial and infrastructure projects.

We are also a certified green building partner and all our products comply with international green norms.

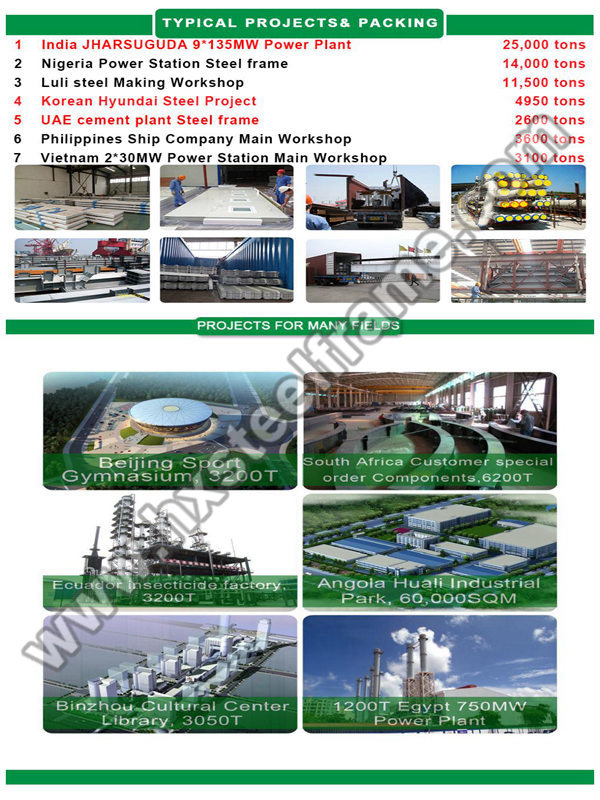

3. Project case- Extended Ship Manufacturing/ Repair Yard& Office Building-Singapore:

Detailed introduction

Location: Singapore, heavy steel structure fabrication work

Tonnage: 2000ton( Including All Main frame and Secondary Structures)

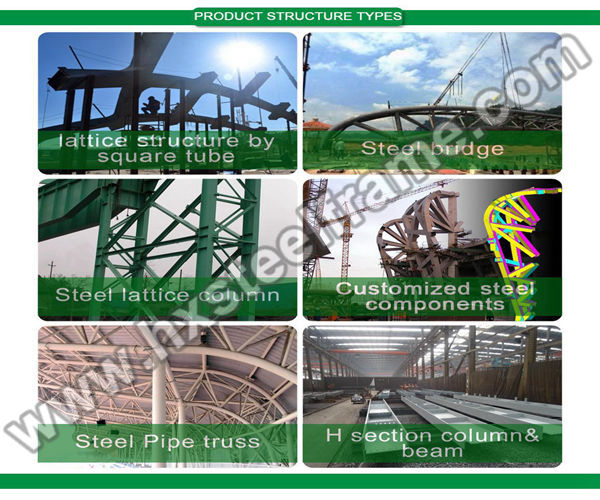

Structure Type: lattice column and truss girder with crane capacity 2x 50T, 1x 32T, 2x 30T, 2x 20T, 2x 15T, 2x 5T.

Execution: October.15, 2012

Difficulty: Material Substitution From British Standard Into Chinese standard and Make the converting and output all the shop-drawings accordingly.

This project, the fabrication standard is as per American standard, all the welders shall have the AWS welder certificate, the 3rd party QC will stay in our factory track the whole fabrication process. Finally after 50 days efforts, our products pass the inspection by client 100% at once. Client feel happy to work with us. Now we are the VIP supplier in client' s list.

4. What you can get from us for your demanded Steel building ( made of prefabricated structures ) :

1) Steel structure special designing and processing

2) EPS sandwich panel( for wall, roof, floor)

3) All construction & decoration materials &downpipe are strictly selected.

4) Designing & Installation drawings( in details)

5) Full support in installation technology & guidance

6) Engineers' guidance on-site in your place is available

7) Custom-made service is available

5. Packaging & Shipping for Steel building ( made of prefabricated structures ) :

1) Using container:

container of 20 feet, and container of 40 feet

2) By sea for batch goods, for container or bulk-cargo ship, port receiving.

3) Customers specifying freight forwarder or negotiable shipping methods

4) All of the steel column& beams ends and plates will be packed by the blanket to protect them from the crash in the container during the shipment.

5) To make the loading and unloading more efficiently and saving the delivery cost, 40' OT is preferred to loading the steel frames.

6) All the wall and roof panels will be filmed by two sides and fixed stably in the 40HQ container.

7) All the windows and doors will be protected by the bubble rapping papers and fixed stably in the container.

6. FAQ:

1) Q: How could I control the cost of building a Steel building ( made of prefabricated structures ) ?

A: Firstly, the designing scheme should be mutually discussed and then accepted. Then, the kinds of building materials should be confirmed since different types and qualities make various prices. After that, we will send you a detailed quotation.

2) Q: How Long does it take to build a Steel building ( made of prefabricated structures ) ?

A: It depends on the size of the warehouse. Generally, the construction period of is 1 month of a 2000-square-meter workshop by a construction team of 8-10 people. It only costs 2-3 weeks to build the steel structure frame.

3) Q: Is it difficult to build a Steel building ( made of prefabricated structures ) ?

A: totally not, you can let your local teams build it according to the construction drawings and erection guiding video provided by us.