|

Shandong Huaxing Steel Structure Co., LTD.

|

modular structures and prefabricated steel structures for Khartoum client

| Price: | 1000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Standard accessary: put into boxes or bag

2. Branded and reputed consumables are used

3. Software: Auto CAD, PKPM, MTS, 3D3S

1. Technical specs for Steel building ( made of modular structures ) :

Specification | Structure type | Heavy steel structure |

Design standard | AISI / ASTM / BS / DIN / GB / JIS | |

Length | With customer's requirement | |

Width | Single span , double-span , multi-span | |

Height | With customer's requirement | |

Components | Bolt | Steel grade 45 |

Column | Q235B , Q345B welded H section steel | |

Beam | Q235B , Q345B welded H section steel | |

Tube | Steel Q235B , Q345B | |

High strength bolt | Cr 40 , 10.9S , 9.8S , galvanization | |

Sleeve | Steel Q235B , Q345B , galvanization | |

Purlin | Q235B C channel or Z channel , galvanization | |

Roof & Wall panel | Sandwich panels , Corrugated steel sheet , FRP sheet |

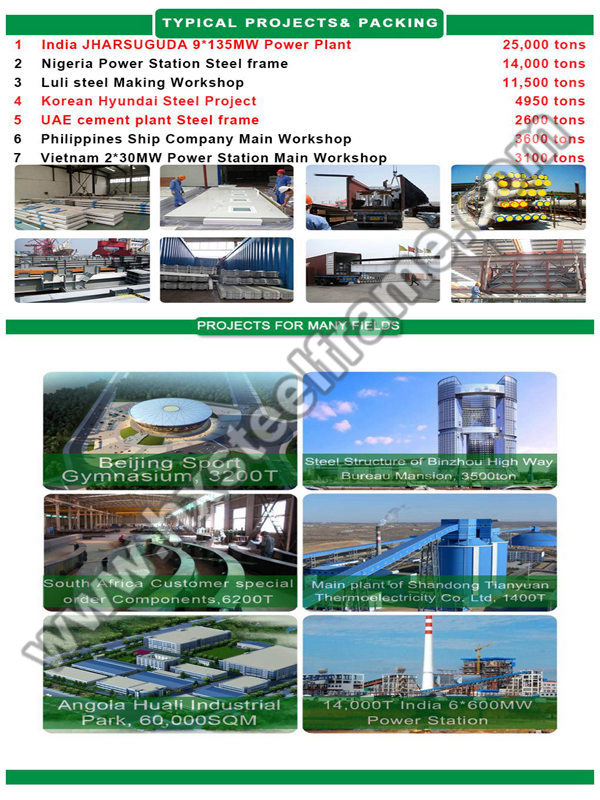

2. Applications of steel structure:

Structural steel fabrication have become increasingly and widely used at the workshops, warehouse, Steel building ( made of modular structures ) and other industrial and civil architectures. For example, single-span and multi-span gantry light-frame structures, exhibition Hall, industrial steel frame, Office buildings, Garage, Multy-story building, Hanger, Agricultural storage, Logistic centers, and all kinds of steel construction, etc.

3. Project case- Extended Ship Manufacturing/ Repair Yard& Office Building-Singapore:

Detailed introduction

Location: Singapore, heavy steel structure fabrication work

Tonnage: 2000ton( Including All Main frame and Secondary Structures)

Structure Type: lattice column and truss girder with crane capacity 2x 50T, 1x 32T, 2x 30T, 2x 20T, 2x 15T, 2x 5T.

Execution: October.15, 2012

Difficulty: Material Substitution From British Standard Into Chinese standard and Make the converting and output all the shop-drawings accordingly.

This project, the fabrication standard is as per American standard, all the welders shall have the AWS welder certificate, the 3rd party QC will stay in our factory track the whole fabrication process. Finally after 50 days efforts, our products pass the inspection by client 100% at once. Client feel happy to work with us. Now we are the VIP supplier in client' s list.

4. Certificates & Quality Management for the Steel building ( made of modular structures ) :

We have ISO9000, 14000, 18000 by BV France, AWS& EN welder, CE etc to ensure our whole production progress controllable.

We also have systematic Quality Process and Progress Control documentation: Our fabrication process have been controlled by series of documentation and quality testing which are monitored and certificated by BV, SGS, SKM, JACOBES etc world-famous third party inspection organization.

5. Packaging & Shipping for Steel building ( made of modular structures ) :

1) Using container:

container of 20 feet, and container of 40 feet

2) By sea for batch goods, for container or bulk-cargo ship, port receiving.

3) Customers specifying freight forwarder or negotiable shipping methods

4) All of the steel column& beams ends and plates will be packed by the blanket to protect them from the crash in the container during the shipment.

5) To make the loading and unloading more efficiently and saving the delivery cost, 40' OT is preferred to loading the steel frames.

6) All the wall and roof panels will be filmed by two sides and fixed stably in the 40HQ container.

7) All the windows and doors will be protected by the bubble rapping papers and fixed stably in the container.

6. FAQ:

1) Is there a clear service life of your Steel building ( made of modular structures ) ? If have, how long ?

Under conventional climate and environment, steel structure whole building 30 years, main structure 50 years, protecting system 30 years.

2) What designs do you have in different climates? How can the Steel building ( made of modular structures ) adopt to different climates?

Strong wind region: improve the wind-resisting ability of the internal structure.

Cold region: increase the thickness of the wall, or use good insulation material, improve anti-pressure ability of the structure.

High corrosion region: use corrosion resistant material, or paint anti-corrosive coating.